Custom Automation

Customized Solutions for Non-Standard Automation Equipment

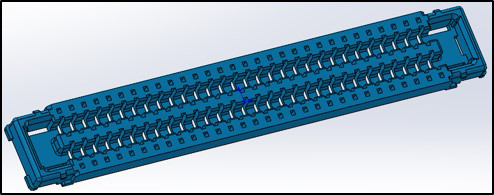

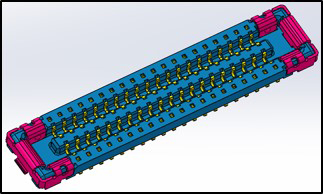

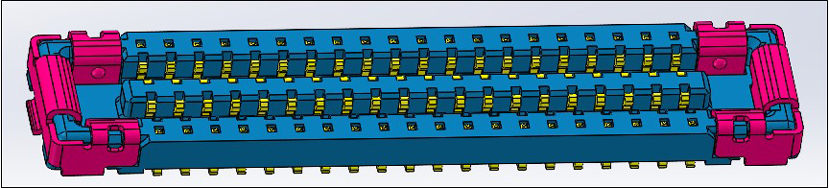

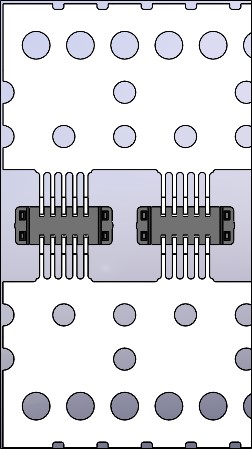

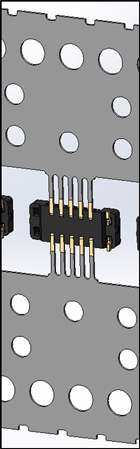

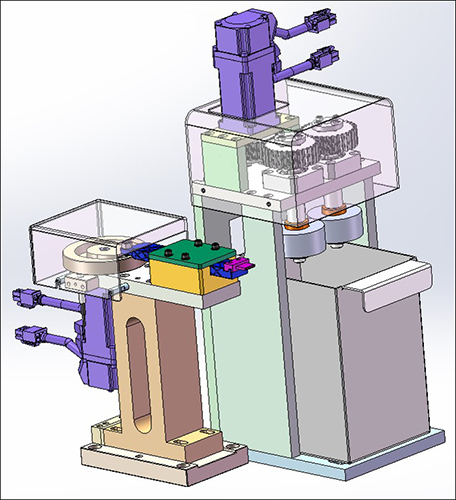

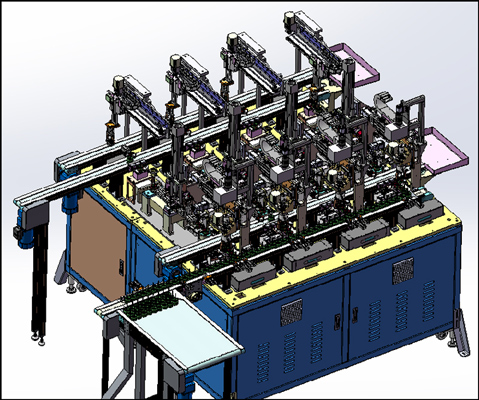

Female End Fully Automatic Pin Insertion Machine

Assembly Section

|

+ |  |

+ |  |

= |  |

Detection Section

| Coplanarity Detection |

|

| GAP Detection |  |

Product Function Introduction

- It belongs to the 3C industry, specifically the consumer electronics sector, and is widely used in the mobile phone industry. BTB series connectors (used for connecting mobile phone motherboards, screens, cameras, etc.) are commonly found in domestic brands such as Huawei, Xiaomi, Oppo, Vivo, and others.

- The product offers a wide range of options to meet the needs of both high-end and low-end mobile phones.

Equipment Function Introduction

- It can complete the assembly of adhesive core (main body) + terminals+post-insertion parts (see details in the previous page graphic introduction), and perform functional testing, rejection of defective products, and packaging of good products. Each tray contains 5000pcs of good products.

- The machine is suitable for producing products with multiple PINs, with quick and convenient replacement.

- Compared to traditional manual operations, this equipment has a high production capacity, fast efficiency, and stable performance of a CCD visual inspection system, eliminating the occurrence of defective products caused by human fatigue, mistakes, etc.

Design Cycle: The design cycle is 45 days, and the processing and assembly debugging is 75 days. UPH=35K/class (40PIN).

|

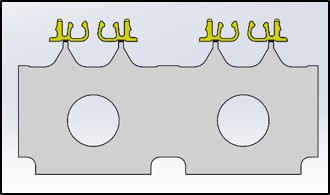

1. CarrierFunction: Arrange the plastic (main body) uniformly and orderly, that is, the main body positioning. |

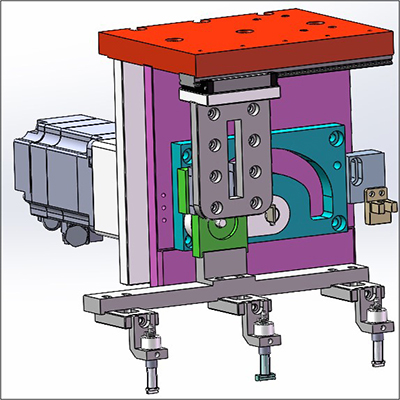

2. Insertion MechanismFunction: Pin Insertion Module, inserts semi-finished products (terminals) into the main body, meeting product functionality and dimensional requirements with an accuracy of within 0.02mm. |

|

|

|

3. Mounting HD ModulesFunction: Insert the main product of the assembled terminal into the back shelf to meet the product function and size requirements, and the accuracy is within 0.02mm. |

4. Cutting and Rotating Module

|

|

| Function: Cutting module, high-precision terminal cutting, punching, riveting, and cutting can be completed by the motor, fast speed and good stability. | Function: 4-station rotary module, complete product direction change and multi-station work, suitable for small spaces and environments with direction change requirements. |

5. Handling and Clamping Correction Module

|

|

| Function: Handling module, with a small size, fast speed, high stability, can be used as an independent handling module, suitable for many occasions. | Function: Clamping and correcting module, this mechanism can be used for positioning of the mechanism with poor repeat positioning accuracy. |

6. Sealing Module

Function: Heat sealing module, can be used with automatic machine or manual semi-automatic use.

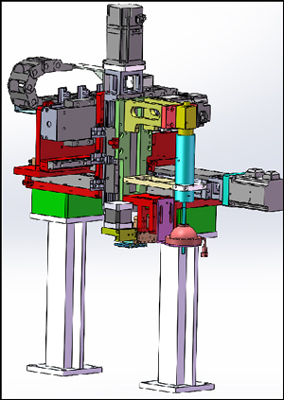

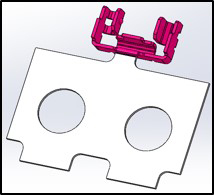

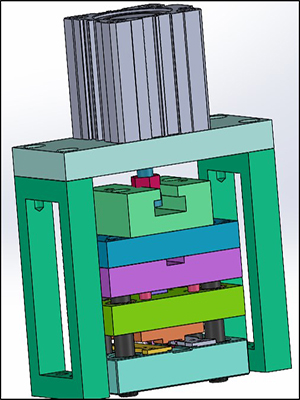

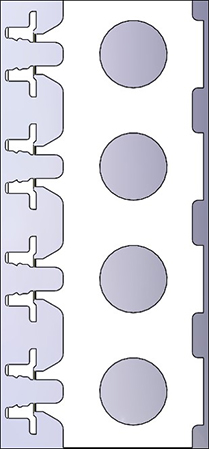

Male End Cam Post-Insertion Machine

|

+ |  |

= |  |

→ |  |

Product Function Introduction

- It belongs to the 3C industry, specifically the consumer electronics sector, and is widely used in the mobile phone industry. BTB series connectors (used for connecting mobile phone motherboards, screens, cameras, etc.) are commonly found in domestic brands such as Huawei, Xiaomi, Oppo, Vivo, and others.

- The product offers a wide range of options to meet the needs of both high-end and low-end mobile phones.

Equipment Function Introduction

- It can complete the assembly of the adhesive core (main body) and post-insertion parts (see details in the previous page graphic introduction).

- The machine is suitable for producing products with multiple pin numbers, with quick and convenient replacement.

- Compared to traditional manual operations, this equipment has high production capacity, fast efficiency, and good product consistency.

Design Cycle: The design time is 35 days, and the processing and assembly debugging is 60 days. UPH=63K/class.

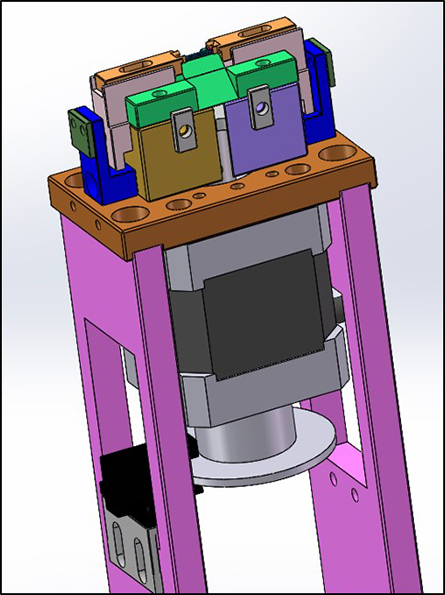

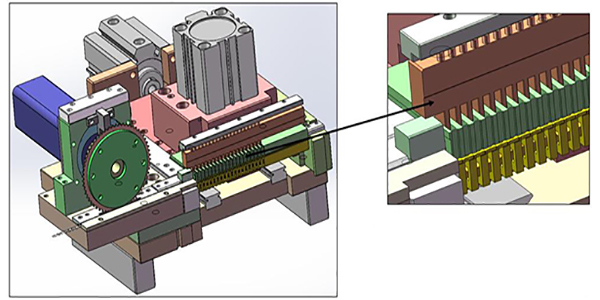

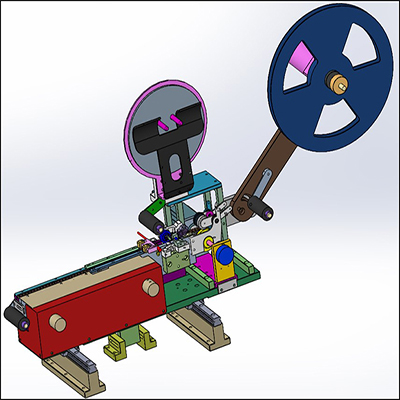

1. Cam Pin Module

Function: Cam pin insertion head, suitable for single insertion of terminals and rear gear, widely used for various connectors, 3C, and other industries.

|

|

2. Sweeping Belt and Shaping Module

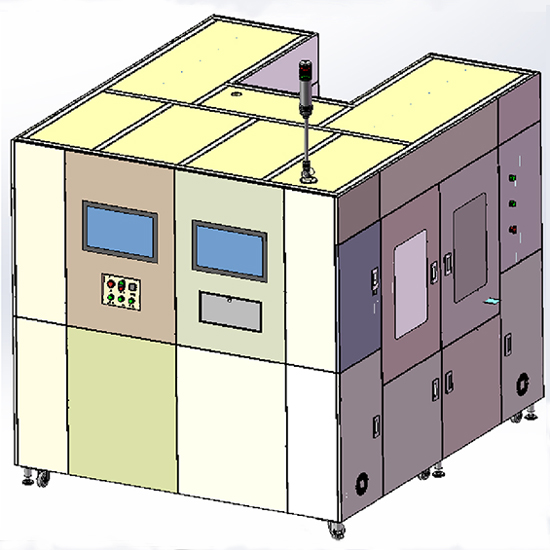

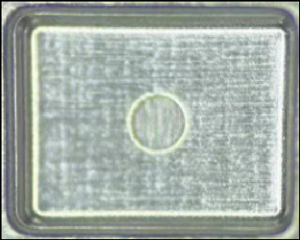

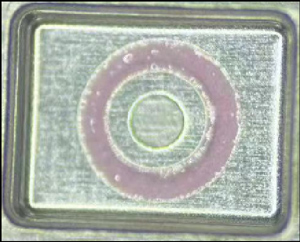

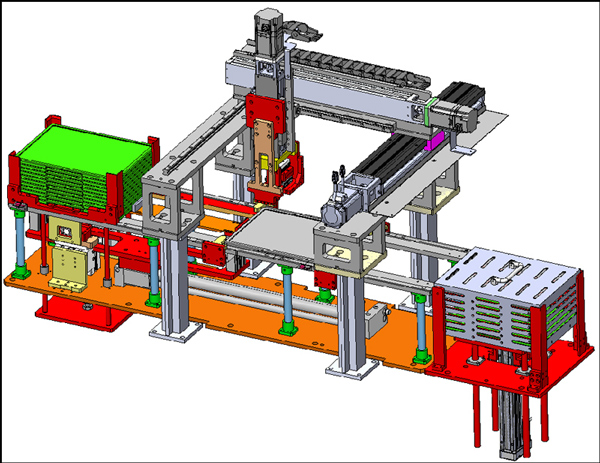

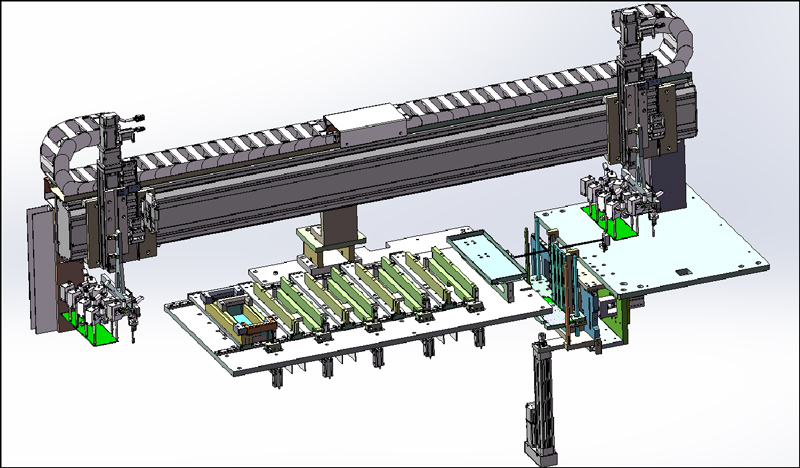

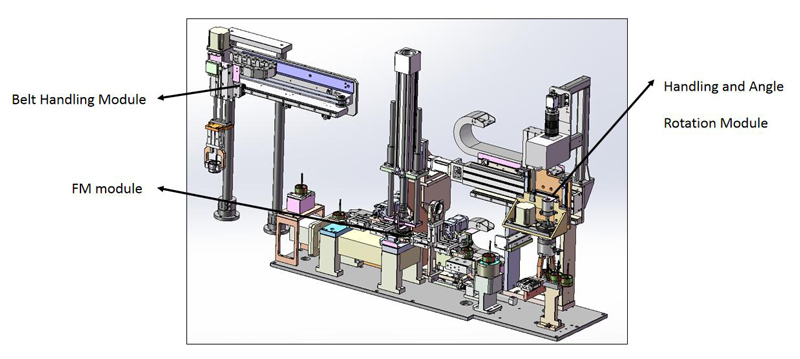

Glue Film Laminating Machine

|

→ |  |

→ |  |

Iron Shell |

|

Dispensing |

Film |

Product Function Introduction

- It belongs to the 3C industry - consumer electronics, which is widely used in the mobile phone industry, and the film it is attached to is a waterproof and breathable film.

- There are many types of products.

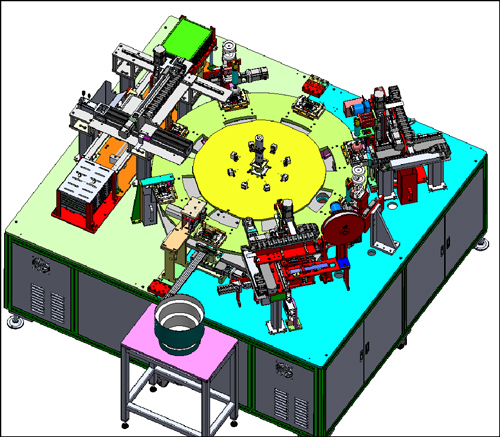

Equipment Function Introduction

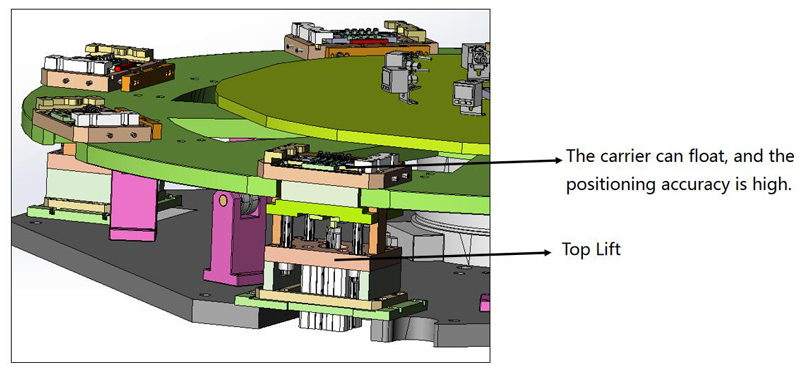

- The vibration plate orderly discharge of materials, the manipulator to the 8-point indexing plate, vehicle floating positioning, visual guidance positioning, dispensing, glue position detection, cutting waterproof blue film, 3-axis manipulator film, gantry mechanical hand material and automatic plate.

- The machine is suitable for the production of a variety of products, quick and convenient replacement.

- Compared with traditional manual operation, this equipment has high production capacity, fast efficiency, CCD visual detection system stable performance, to eliminate manual fatigue, and errors caused by bad outflow.

- Material taking manipulator, cutting module, gantry manipulator, automatic disk changer, etc. can be used as non-standard module, independently disassembled to sell.

Design Cycle: The design time is 45 days, the processing is 25 days, and the assembly and debugging is 70 days, a total of 140 days.

Length x Width x Height: 2.2m x 2m x 1.8m.

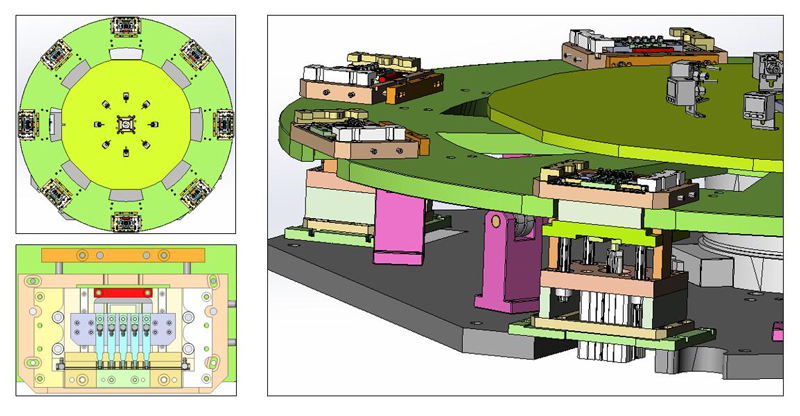

1. Turntable and Floating Positioning Module

2. Dispensing Module |

3. Cutting and Filming Module |

|

|

|

Self-made 4-axis module, completes the dispensing function, fast speed, high precision, with a camera positioning system, precise positioning and detection. |

Self-made 3-axis module, combined with the punching die and camera positioning module, has high speed, high precision and wide application. |

4. Cutting and Placing Module

The self-made gantry handling module, combined with the automatic disk changing mechanism, can realize automatic disk changing and save manpower.

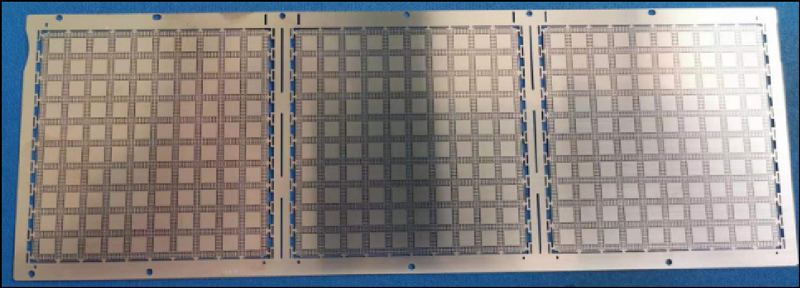

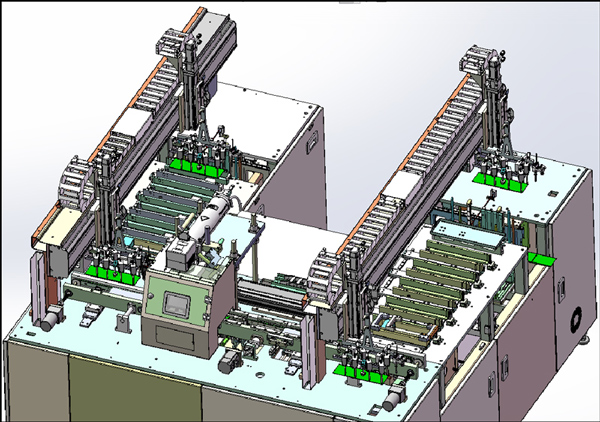

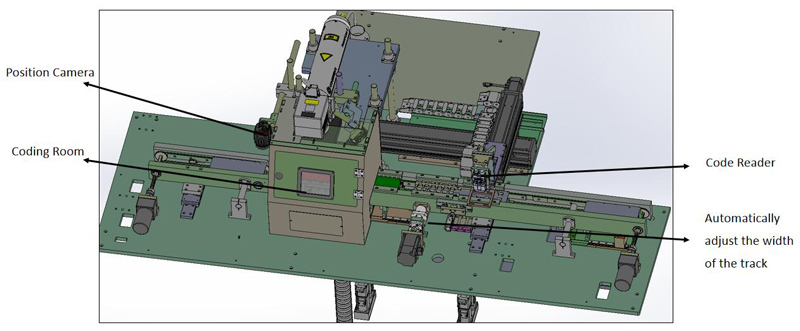

2D Marking Coding Machine

Product Function Introduction: It belongs to the semiconductor industry.

Equipment Function Introduction

- Laser engrave the QR code on the semi-finished product, and complete the inspection and blanking.

- The machine is suitable for the production of various products, and the replacement is quick and convenient.

- Compared with traditional manual work, it has high production capacity, fast efficiency, automatic identification of QR codes, and prevents bad outflows.

- Eliminate the tedious wearing process of manual work (gloves, electrostatic wristbands, etc.).

Design Cycle: The design time is 40 days, the processing is 25 days, and the assembly and debugging is 60 days, a total of 125 days.

Length x Width x Height: 2.1m x 1.9m x 1.9m.

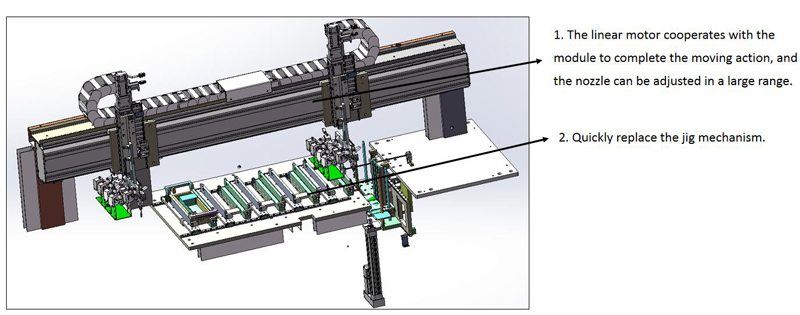

1. Loading, Handling and Isolation Belt Storage Module

- The linear motor cooperates with the module to complete the moving action, and the nozzle can be adjusted in a large range.

- Quickly replace the jig mechanism.

2. Positioning, Coding and Reading Module

3. Unloading, Handling, NG and Isolation Belt Storage Modules

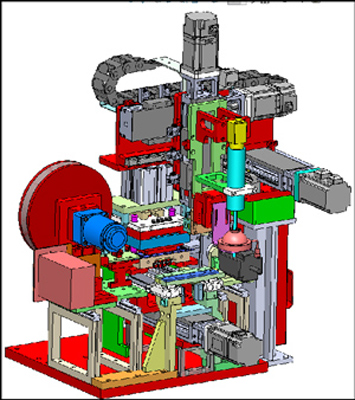

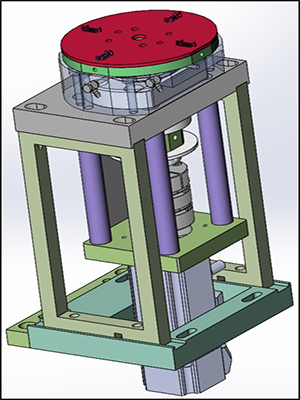

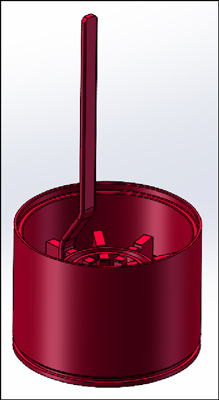

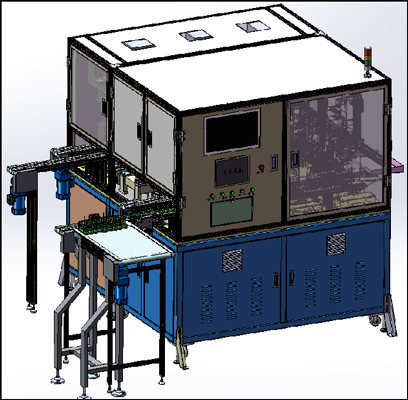

Anode Correction Frequency Modulator

|

|

Product Function Introduction

- It belongs to the home appliance industry.

- For microwave ovens and home appliances, it is understood that Midea is the only microwave oven factory in China to realize automatic production. It is highly scalable.

Equipment Function Introduction

- Product antenna correction, frequency adjustment and detection, OK & NG product classification and outflow.

- It is suitable for producing a variety of products, with no need to replace any parts, and can be switched with one key.

- The overturning module and the belt feeding module can be sold as independent modules, or customized according to customer needs.

- It has high production capacity and fast efficiency compared with traditional manual work. One machine can save 2 people/shift and 4 people/day.

|

|

|

|

Loading, Vision Correction, Flipping, Frequency Modulation and Unloading Modules

Above, ATO store provides a variety of customized automation solutions for non-standard equipment, including female end fully automatic pin insertion machine, male end cam post-insertion machine, glue film laminating machine, 2d marking coding machine, and anode correction frequency modulator, please contact us if you need it.