Temperature Sensor

High Temperature Infrared Sensor, Non-Contact, 4-20mA Output

Industrial Laser Infrared Temperature Sensor, 300 ~ 1400℃

Infrared Temperature Sensor for Human Body

Infrared Temperature Sensor, Non-Contact, 0 ~ 1200℃

Infrared Temperature Sensor, Non-Contact, 4-20mA Output

Infrared Temperature Sensor, Non-Contact, 4-20mA/ RS485 Output

Non-Contact Infrared Temperature Sensor with Display

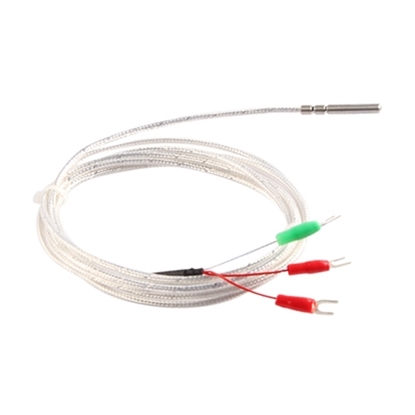

RTD Sensor Probe, Pt100, 3 Wire

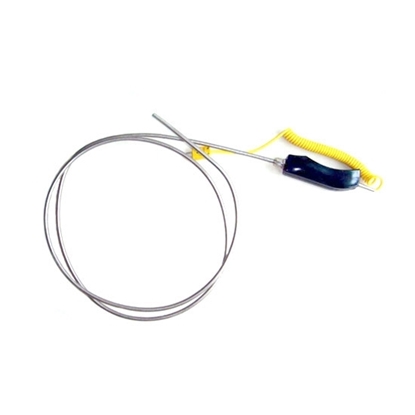

Thermocouple, K type, Sheath

Thermocouple, E type, Sheath

Thermocouple, J type, Sheath

Thermocouple, T type, Sheath

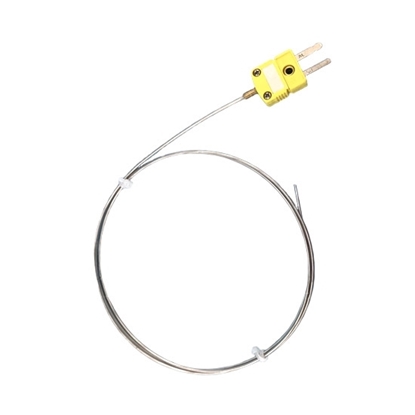

K type Thermocouple Probe, Sheath Diameter 1mm

Thermocouple, S type, Assembly

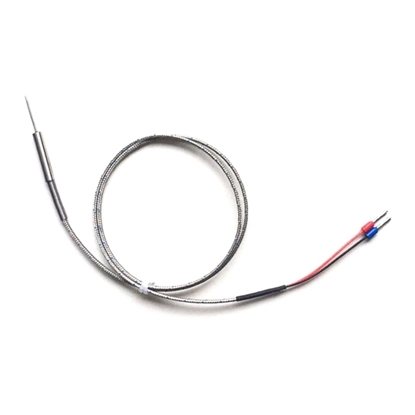

Thermocouple, K type, Assembly

Thermocouple, E type, Assembly

Thermocouple, B type, Assembly

Thermocouple, J type, Assembly

Thermocouple, T type, Assembly

Thermocouple, N type, Assembly

Cheap price temperature sensors for sale online. Temperature sensors are sensors that sense temperature and convert it into a usable output signal. They are the core components of temperature measuring instruments. Temperature sensors are used in temperature detection, display, temperature control, overheat protection and other fields. ATO provides you with different types of temperature sensors, such as thermocouples, RTD sensors, infrared temperature sensors, and thermistor temperature sensors. You can choose temperature sensors with different temperature detection ranges on our website, from -200℃ to +1600℃.

ATO's Temperature Sensor Types

Thermocouple:

Thermocouples measure temperature by generating thermoelectric potential through the temperature difference at the junction of two different metals. They have an extremely wide temperature measurement range (such as K type and B type), fast response speed, and no external power supply is required, but the accuracy is low and cold end compensation is required. It is suitable for fast or extreme environment temperature measurement, such as high-temperature industry.

Thermocouples measure temperature by generating thermoelectric potential through the temperature difference at the junction of two different metals. They have an extremely wide temperature measurement range (such as K type and B type), fast response speed, and no external power supply is required, but the accuracy is low and cold end compensation is required. It is suitable for fast or extreme environment temperature measurement, such as high-temperature industry.

RTD Sensor:

Resistance temperature detector sensors use the characteristics of metal resistance changing linearly with temperature. They have high accuracy and good stability, but they need a constant current power supply and slow response. They are widely used in laboratories, chemical process control and other scenes that require long-term stability and high accuracy.

Resistance temperature detector sensors use the characteristics of metal resistance changing linearly with temperature. They have high accuracy and good stability, but they need a constant current power supply and slow response. They are widely used in laboratories, chemical process control and other scenes that require long-term stability and high accuracy.

Infrared Temperature Sensor:

Infrared temperature sensor realizes non-contact temperature measurement by detecting infrared energy radiated by objects. It has extremely fast response, but is affected by emissivity, distance and medium. It is suitable for moving objects (such as motor bearings), human body temperature measurement or dangerous environments.

Infrared temperature sensor realizes non-contact temperature measurement by detecting infrared energy radiated by objects. It has extremely fast response, but is affected by emissivity, distance and medium. It is suitable for moving objects (such as motor bearings), human body temperature measurement or dangerous environments.

Thermistor Temperature Sensor:

The thermistor relies on the resistance change characteristics of semiconductor materials. It has high sensitivity but strong nonlinearity. It is small in size and low in cost. It needs to pay attention to the self-heating effect. It is mostly used in low-cost scenarios with narrow temperature range such as home appliances (air conditioners, refrigerators) and battery management.

The thermistor relies on the resistance change characteristics of semiconductor materials. It has high sensitivity but strong nonlinearity. It is small in size and low in cost. It needs to pay attention to the self-heating effect. It is mostly used in low-cost scenarios with narrow temperature range such as home appliances (air conditioners, refrigerators) and battery management.

How to Choose a Temperature Sensor?

When choosing a temperature sensor, it is necessary to consider the application scenario, measurement requirements and environmental conditions comprehensively. The following are several key factors that can help you make a reasonable choice.

- Measurement range and accuracy requirements: If you need to measure high temperature, thermocouples are a common choice. For medium and low temperature and high precision occasions, RTD sensors are more suitable. If you only measure changes in the normal temperature range, such as ambient temperature, you can choose a thermistor or a digital temperature sensor. If the object is not touchable, you can choose an infrared sensor.

- Response time: Select the appropriate temperature sensor based on the required measurement time. Systems that require fast response (such as real-time control systems) should use sensors with fast response speed. RTD and some digital temperature sensors may have relatively slow response speed, but high accuracy.

- Installation environment: Choose the right temperature sensor based on the installation environment. In high vibration, high humidity or chemical corrosion environments, it is necessary to select sensors with firm packaging and protection level. If it is an embedded system, pay attention to the size and installation method of the sensor.

Precautions for Using Temperature Sensors

- The installation position should be reasonable: The temperature sensor must be close to or deep into the object to be measured to avoid air interlayer affecting the measurement results. For example, when measuring the temperature of a pipeline, it should be buried in the pipe wall as much as possible or a special temperature measuring sleeve should be used. The sensor should be installed away from heat sources, vents or other interference sources.

- Avoid electromagnetic interference: Sensor signal lines (especially analog outputs such as thermocouples) are easily interfered with. Shielded wires or twisted pairs should be used, and they should be away from strong electrical interference sources such as high-power power lines, inverters, and motors. At the same time, ensure good grounding.

- Pay attention to the measurement range and environmental adaptability: Do not use the temperature sensor beyond its temperature range. For example, thermistors are prone to burn out at high temperatures. For harsh environments (such as high humidity and high corrosion), you should choose a model with a higher protection level and add a protective sleeve if necessary.

- Regular calibration and inspection: Temperature sensors may drift over time, especially RTD and thermocouples. The measured values should be calibrated or compared regularly to ensure accuracy. If abnormal readings are found after long-term use, they should be replaced or recalibrated in time.

- Correct and reliable wiring: Different sensors have different wiring methods (2 wire, 3 wire, 4 wire system). Before installation, the corresponding pins should be carefully connected. Loose or reverse connection can easily lead to measurement errors or damage the equipment.

Application of Temperature Sensors

- Industrial automation and process control: In power plants, chemical industry, metallurgy, pharmaceutical and other industries, temperature control is related to safety and efficiency. Temperature sensors are used to monitor the temperature of key positions of reactors, pipelines and furnaces, and the system realizes automatic heating, cooling, alarm and other control functions.

- Household appliances: Air conditioners, refrigerators, rice cookers and water heaters are all equipped with built-in temperature sensors for temperature detection and control. Air conditioners adjust the cooling intensity according to the room temperature, and rice cookers judge the stage of the heating process by temperature changes.

- Automotive electronics: Modern cars use a large number of temperature sensors to monitor engine coolant temperature, oil temperature, intake temperature, battery temperature to ensure engine performance, battery life and vehicle safety.

- Medical equipment: In medical and laboratory equipment such as thermometers, incubators, ventilators, laboratory culture equipment, etc., temperature sensors are used to detect human body temperature, maintain a constant temperature environment or monitor sample status.

- Environmental monitoring: In meteorological stations, smart agriculture, and building automation systems, temperature sensors are used to monitor environmental temperature and humidity, regulate greenhouses, air conditioners, fresh air systems, etc., to improve comfort and energy efficiency.