Gas Detector, Gas Leak Detector

A gas detector is an instrument used for the gas leakage concentration detection. The gas detector works mainly by using gas sensor inside to detect the presence of gas in the environment. The gas sensor serves as a reference point or scale which is the core part of gas leak detectors. Different gas sensors can react to different gases, so that the gas detector can detect different types and concentrations of gases. When the detected gas concentration exceeds the preset value, the alarm will sound to warm the user. So, it is an essential part of safety system to safe guard your life.

Contents

- What Types of Gases can Gas Detectors Monitor?

- What are Different Types of Gas Detectors?

- How Does a Gas Detector Work?

- How to Select a Right Gas Detector?

- How to Calibrate a Gas Detector?

- How to Install a Fixed Gas Detector?

- What Can You Buy on ATO.com?

What Types of Gases can Gas Detectors Monitor?

Then, what kinds of gases can be detected by gas detectors? There are usually tree categories of the gases to be measured by gas detectors in daily life and work, that is, combustible gas, toxic gas and VOC (Volatile organic compounds).

• Combustible gas

Combustible gas is the most common gas type which need to be monitored by gas detector. The combustible gas refers to the gas that can be evenly mixed with air (or oxygen) in a certain concentration range to form premixed gas, which will explode when it meets the fire source and release a large amount of energy during combustion. Such gases are ubiquitous in the working environment of oil chemical industry, chemical manufacturing, etc.

The common combustible gas includes hydrogen (H2), carbon monoxide (CO), methane (CH4), ethane (C2H6), propane (C3H8), butane (C4H10), ethylene (C2H4), propylene (C3H6), butene (C4H8), acetylene (C2H2), propiolic (C3H4), butyl acetylene (C4H6), hydrogen sulfide (H2S), phosphine (PH3) and so on.

Some gas detectors can detect only one kind of gas, while others can detect many kinds of gases. When choosing a combustible gas detector, it should be determined according to the environment on site. If the working environment is relatively simple, there is only a single gas, then we will choose a single gas detector. But the real working environment is very complex, and we often meet with mixture of several gases, such as liquefied petroleum gas, natural gas, gas, etc., which contain several kinds of combustible gas in the gas. In such case, we need a multi-gas detector, which can detect those what kind of combustible gas content in the mixed gas is high to avoid the danger of burning and explosion.

• Toxic gas

Toxic gas refers to the gases that is harmful to human body, even causing poisonous. It is mainly divided into excitant gas (can irritate the eyes and respiratory tract mucosa) and asphyxiating gas (can result from a lack of oxygen to the body). These gases can cause harm to human body directly, and also is very dangerous.

The common poisonous gases have carbon monoxide (CO), hydrogen sulfide (H2S), ammonia (NH3), chlorine (CL2), sulfur dioxide (SO2), and so on.

When the gas detector monitors the toxic gas, we generally quantify the toxic gas through several levels:

- TWA: 8-hour weighted average concentration, usually sampled once every 15 minutes. Working under this concentration for 8 hours does not affect health.

- STEL: 15-minute weighted average concentration, usually sampled once every 5 minutes. People staying below this concentration for 15 minutes will not cause irreparable damage.

- IDLH: An immediate threat to life and health concentration, sometimes called an immediate lethal dose. People at this concentration will die immediately or lose the ability to escape.

- MAC: Maximum permissible concentration. Below this concentration, workers are engaged in productive work for a long period of time without causing any acute or chronic occupational hazards.

Knowing the four levels above, we can use the number on the gas detector or alarm signal to determine whether the toxic gas in our work environment is leaking or causing harm to our body.

• VOC (Volatile Organic Compounds)

VOC refers to any self-volatile organic liquids or solids at normal temperature and pressure, usually called organic solvents. The VOC gas detector can detect gasoline, diesel, benzene, crude oil, paint, etc.

The gas detectors are widely used in photovoltaic power generation, garbage power generation, waste gas treatment, natural gas, electric power, pharmaceutical, chemical industry, food, tobacco, casting, iron and steel, mining, oil, gas, petroleum, paper industry, shipbuilding and shipping, painting, sewage treatment and other industries that can produce special gases.

What are Different Types of Gas Detectors?

There are many kinds of gas detectors. Here are some classifications of gas detectors from different angles, which will help you choose which type of detector to buy.

- According to different detected gases, there are combustible gas detectors, toxic gas detectors, common gas detectors, and special gas detector. The price varies, ranging from hundreds to thousands, even to tens of thousands.

- According to functional classification, there are single-gas detector and multi-gas detector. The single gas detector is mainly used to detect a kind of gas in the detection occasion. The multi gas detector has 4 in 1 gas detector, 5 in 1 gas detector, 6 in 1 gas detector, etc., which can detect the presence of one or more gases with one device. The commonly-used multi gas detector is the 4-gas detector used to monitor LEL, CO, O2 & H2S gas leakage.

- According to mode of use, it can be classified into portable (handheld) and fixed (online, wall-mounted). Selecting which type of gas detector usually depends on the use scenario. Portable gas detector is used for safety detection by field operators before operation. Fixed type gas detector mainly realizes continuous detection for a long time, so as to ensure the safety of the site, and does not need on-site personnel control and can be intelligently interconnected.

- According to the sampling method, there are diffusion type and pump-suction type. The diffusion gas detector makes the gas detection with the contact to the gas at the detected area. It means the worker have to enter in the place where the detected gas is located. However, the cost is relatively low. The pump type gas detector can draw the gas sample with a built-in pump, so it has a fast response time and allow the worker to take the measurement at a relatively remote distance and ensure the worker safety.

- According to the detection principle, there are many types of gas sensors to detect different gases, including electrochemical, semiconductors, oxidation, catalytic, photoionization, infrared, etc.

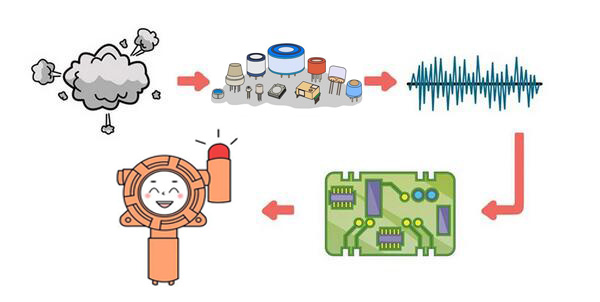

How Does a Gas Detector Work?

The working principle of the gas detector mainly depend on the gas sensor, the core components of the gas detector. Different gas sensors have different principles when detecting gas leakage. Understanding the working principle of the gas detector can help you deal with the small faults of the gas detector in our daily work. The following will give you several common gas sensor structure and principle.

• Electrochemical

Electrochemical gas sensor is used to measure the current produced by the detected gas either being chemically oxidized or reduced at the electrode so as to obtain the concentration of the gas. A considerable part of the flammable, toxic and harmful gases have electrochemical activity, which can be oxidized or reduced. Through the reaction, the composition and concentration of the gas can be distinguished.

Electrochemical sensors are suitable for toxic gas detectors to monitor CO2, H2S, NO, NO2, CLO2, HCN, NH3, PH3 and various toxic organic compounds.

• Semiconductor

Semiconductor sensors are made of metal oxide semiconductor materials. At a certain temperature, the electrical conductivity changes with the gas composition of the environment. Tin dioxide is the most commonly used material in semiconductor sensors. For example, semiconductor sensors are used for alcohol detection, based on the principle that the resistance of tin dioxide decreases dramatically when it encounters alcohol gas at high temperatures.

Semiconductor gas sensors can be used effectively to detect methane (natural gas, methane), alcohol, carbon monoxide, hydrogen sulfide, ammonia (including amines, hydrazine). The semiconductor gas sensor is inexpensive, suitable for civil gas detection, but it has poor stability and is greatly affected by the environment. Therefore, it is not suitable for the place with accurate measurement requirements.

• Catalytic bead

The catalytic bead sensor works based on Wheatstone-Bridge principle, that is, when the induction resistance and combustible gas in the environment have non-flame combustion, the heat changes the resistance value of the induction resistance, and the bridge balance is lost, making it output a stable current signal which is proportional to the combustible gas concentration.

The catalytic bead sensor is usually used to detect combustible gas. It has accurate detection, fast response, long life and low price. However, most of the element organic compound vapor has toxic inhibition to the sensor.

• Thermal conductivity

Each gas has its own specific thermal conductivity. When two or more gases differ greatly in thermal conductivity, thermal conductivity elements can be used to distinguish the content of one of the components. Such sensors have been used to detect hydrogen, carbon dioxide and high concentrations of methane. However, this kind of gas sensor can be applied in a narrow range with many limiting factors.

• Photoionization

Photoionization detector (PID) uses an UV light source to convert organic compounds in the detected gas into positive and negative ions (ionization) that can be detected. The detector measures the charge of the ionized gas and converts it into a current signal, which is amplified and displayed as a "PPM" concentration. After being detected, the ions recombine to form gases and vapors.

PID is suitable for a large number of organic compounds containing carbon including aromatics and alkyl iodides; olefins, sulfur compounds, amines, ketones, ethers, alkyl bromides and silicate esters; organic esters, alcohols, aldehydes and alkanes, ammonia, arsenic, selenium, bromine and iodine, etc.

• Infrared

Infrared gas sensor (IR) uses the selective absorption characteristics of different gas molecules in near infrared spectrum; through the relationship between gas concentration and absorption intensity (Lambert- Bill Lambert law), identify gas components and determine their concentration.

Infrared sensor is widely used in the detection of a variety of gases, and features high reliability, good selectivity, high precision, no toxic, less interference by the environment and so on. The IR sensor can be used to detect carbon dioxide and methane. ATO portable CO2 detector adopts the infrared sensor with increased accuracy and stability.

How to Select a Right Gas Detector?

Through the above introduction, we have a general understanding of the types of gas detector. It is helpful for us to choose a suitable gas detector. For various kinds of production occasions and testing requirements, choosing a right gas detector does matter with the safety of life and property. The following factors can be taken into consideration for selection of gas detector.

• Gas Type

Each production section will encounter different types of gas leaks. Therefore, when selecting a gas detector, all possible scenarios should be taken into account.

If methane and other less toxic alkanes are in the majority, LEL detector is undoubtedly the most appropriate choice. This is not only because the LEL detector is simple in principle and widely used, but also it is convenient for maintenance and calibration.

In the presence of toxic gases such as carbon monoxide (CO) and hydrogen sulfide (H2S), a specific gas detector is preferred to select in order to ensure the safety of workers.

If there are more organic toxic and harmful gases such as aromatic hydrocarbons, halogenated hydrocarbons, ammonia (amine), ethers, alcohols, lipids, etc., considering the low concentration that may cause poisoning of personnel, the photoionization detector should be chosen, while LEL detector is never used, because it may cause casualties.

If the gas type covers the several gases above, choosing a multi gas detector may achieve twice the result with half the effort.

• Measuring range

Each kind of poisonous and harmful gas detector has its fixed detection range. Only when the detection is completed within the measuring range can the instrument be ensured to carry out the measurement accurately. The sensor may be permanently damaged if the sensor is measured for a long time beyond the measurement range. For example, chlorine (Cl2) gas detector has a 0-10 PPM range, and if the detector is accidentally used in an environment over 10PPM, the sensor may burn out completely.

Therefore, before the purchase of gas detection instruments, it must confirm the range you need. The gas detector measuring range is generally chosen to be 150% of the measured gas concentration on site. Do not use the gas detector with large measuring range to test very low concentrations, as the accuracy cannot reach. Also do not exceed the range of use, this will cause gas detector sensor poisoning, overload and early failure.

• Environmental conditions

The environmental conditions involve temperature, humidity, pressure, other gas interference, production process, and so on, which may affect the accuracy, sensitivity and reliability of gas detectors.

When detecting gas leakage, we usually use a single gas detector to detect a particular gas. However, there is usually more than one gas in the detection environment, so we should pay attention to whether other gases will interfere with the detection of the gas detector and make the detection results inaccurate.

Different industrial environments also decide different type selection of gas detectors, portable or fixed style. Portable gas detector or hand-held gas detector, can be carried around to detect the gas anytime and anywhere. Fixed gas detector refers to an instrument fixed in a certain area and used for real-time monitoring of the gas environment in the area. It can maintain a 24-hour continuous monitoring and can effectively interact with other equipment. For example, the fixed type gas detector is suitable for the long-term operation of leakage detection in production or storage positions; portable or hand-held gas detection instruments are used for overhaul detection, emergency detection, entry detection and circuit detection.

• Functions

Now the gas detectors have many additional functions, such as waterproof, dustproof, explosion-proof, data logging, data transmission, etc., which should be selected according to the actual needs.

• Ease of Use

For use of fixed style gas detectors, the wiring and installation is essential to consider while portable or handheld gas detector is relatively easy to operate for the user. However, no matter what kinds of gas detectors, regular calibration is necessary. Before use of the gas detector and after change of gas detector, it must calibrate the gas detector to ensure the accuracy of the gas detector and indeed play the role of safe protection.

How to Calibrate a Gas Detector?

When the gas detector is used for a period of time, the instrument accuracy will be affected by use environment, the sensor loss, misoperation or interfering gas. In order to ensure the instrument accuracy and use safety, gas detectors must be calibrated periodically. Generally, gas detectors are calibrated once a year, and strictly, the instrument will be calibrated every six months or every three months. The more times of calibration, the less prone the detector to drift and the better the detection effect.

To put it simply, the calibration of gas detector requires two steps: firstly, reset the instrument to zero in "air" without containing gases to be measured; secondly, the instrument is calibrated with standard gases with known concentration. For specific calibration procedure of ATO portable gas detectors, you are suggested to refer to the user manual.

Due to the difference of sensor in gas detectors, the calibration method is also different. Here we take the ozone (O3) gas detector as an example. Ozone gas detector is commonly used in industrial laboratories, and now it is mostly calibrated by chemical titration method, which is internationally recognized as one of the calibration method. Its principle is to use strong oxygen ozone chemicals to react with potassium iodide, allowing free iodine out into the water, causing water color change; after the use of sodium thiosulfate standard solution for titration, free iodine converted into sodium iodide, and the end of the reaction is complete discoloration of water. In addition to chemical titration method, gas detectors can be calibrated with standard calibration gas, which are commonly used by manufacturers of gas detectors.

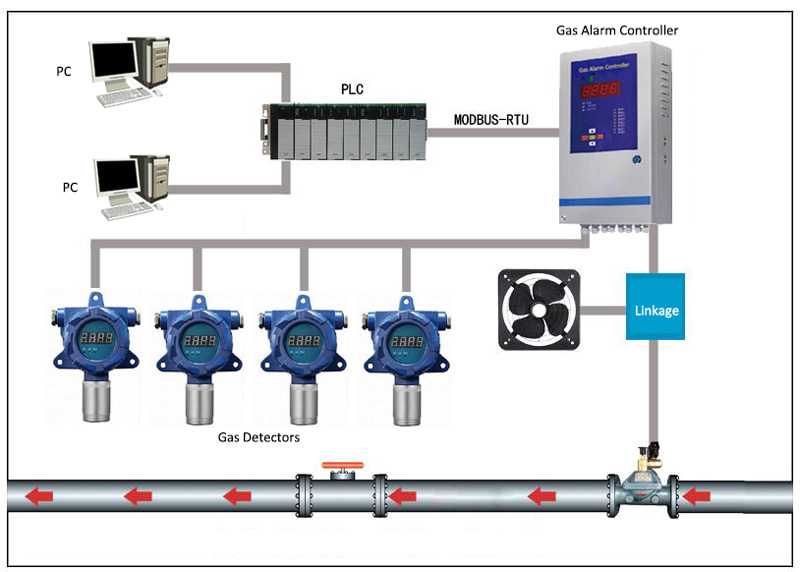

How to Install a Fixed Gas Detector?

In the petroleum industry, chemical industry and other industries existing some dangerous gases, gas detector is essential equipment to ensure the safety of our life and production. Generally, fixed gas detector is selected, which can be installed at a certain detection point. The fixed type gas detector and alrm can not only detect the gas concentration in working environment, and when gas concentration exceed the specified value, it will send out sound and light alarm and through the linkage with solenoid valve, cut off the gas source at the same time and start the exhaust or spray device, which can effectively avoid the risk of gas leakage. So how should we install the fixed gas detector after we buy it? Let’s share the installation steps of the fixed gas detector and gas alarm.

First of all, it need to see which gases need to detect, and whether there are national or local regulations or installation codes on fire protection or construction when installing the detection equipment, and whether there are relevant industrial safety standards when installing such gas detectors, etc. These regulations or installation specifications are what we have to follow.

Second, it should find the risk points for the gas, and figure out which are leakage points and receptor points. The leakage point is the place where dangerous gases can escape from. The receptor point is a location where dangerous gases can pose a threat to people, property or equipment. Although most devices have many leakage and receptor points, these two categories of risk points are not always in the same place. For example, a potential leak could be in a nearby plant, but the receptor point may not be limited to the plant, and may involve a wider area. To identify the leakage point, we shall refer to all hazard area classification maps, process safety management and risk management plan, etc. Generally, the fixed gas detector should be installed close to the potential leakage point. The gas leak detector and alarm should be installed in locations where there are likely to cause damage or injury to personnel, even if there is no specific leak nearby.

Then, determine the exact installation location of gas detector and carry out installation operation. The installation of gas detector must be firm and should be fixed in the corresponding position with expansion screws. At the same time, we also need to adjust the installation position of the gas detector according to different gases detected. When the detected gas is heavier than air, the installation height of the gas detector should be 0.3m ~ 0.6m from the ground. When the detected gas lighter than air, the installation height of gas detector should be 0.5m ~ 2m higher than the release source. Do not install gas detectors at the following locations:

- Places directly affected by steam and lampblack.

- Air supply ports, ventilation fans, room doors and other places with large air flow.

- Places where water vapor and water drop are abundant.

- Temperature below -40℃ or above 70℃.

- Places with strong electromagnetic fields.

Finally, do the wiring of fixed gas detector, to let gas detector receive signals of the controller. The wire adopts a highly shielded wire to prevent the electrical signal interference. The wiring should be carried out in accordance with the wiring diagram of fixed gas detector user manual. After the wiring is completed, power on the detector and check whether the gas detector can work properly.

What Can You Buy on ATO.com?

ATO.com is one-stop online shop for all kinds of automation electronics, equipment and devices like motors, motor controllers, power supplies, sensors, passive components, test & measurement instruments, tools, etc., with high quality, reasonable price and awesome service. So it is also your reliable source of gas detectors and gas analyzers to suit your different applications.

5 best gas detectors to buy on ATO.com

ATO best sellers of gas detectors are shown in the below table. To get more details and price list of gas detectors, please move to our product pages.

ATO gas detector

Here you can find both portable gas detectors and fixed gas detectors to fit your needs. Our gas detectors are your best gas leak detection solution for ammonia (NH3), carbon monoxide (CO), hydrogen sulfide (H2S), carbon dioxide (CO2), chlorine (Cl2), hydrogen (H2), nitrogen (N2), ozone (O3), etc. With high accuracy and fast response time, our gas detectors come with various measuring range for options. Once the detected gas leak concentration exceeds the preset alarm point, the detector will give you alarm to safeguard your life.

• Portable / Handheld Gas Detector Features

- Big LCD dot matrix display, easy to read gas type, unit, concentration, local time, etc.

- Built-in micro-sampling pump, 10 grades of suction are available.

- Explosion-proof certification

- With self-calibration and zero calibration functions, making gas detection more accurate and reliable.

- One key to restore factory setting, free from maloperation.

- Two-stage alarm with sound and light, and alarm point is settable.

- Large capacity rechargeable lithiumpolymer battery for long running time.

- High-strength special engineering plastic housing, with anti-slip, waterproof, dustproof and explosion-proof.

- Optional data logging function for high-speed data transmission by USB to computer.

• Fixed Gas Detector Features

- Adopting high precision sensor for accurate gas leak detection.

- Equipped with 3-wire system analog output or RS485 output (optional).

- Explosion-proof design, relaible and stable.

- Infrared ray controller can remote control the alarm point settings, zero calibration, and address modification.

- Two-stage alarm with sound and light, and the alarm point is settable.

- With self-calibration function, and three standard keys will be used to realize on-site maintenance.

ATO gas analyzer

In addition to gas detectors, gas analyzer is an analysis instrument for gas composition. Due to the diversity of gases being analyzed and the variety of analysis principles, there are many kinds of gas analysis instruments, and the commonly used are thermal conductivity gas analyzer, electrochemical gas analyzer and infrared absorption analyzer, etc.

ATO provides you a portable gas analyzer with a modular design, allowing it to detect up to 18 gases simultaneously with high precision and fast speed. This portable multi gas analyzer is suitable for the university laboratory, research institute, large oil refinery, metallurgical plant, inspectation and quarantine bureau, hospital, mines, tunnel engineeringsite, etc

• Portable Multi-Gas Analyzer Features

- Using world top brand sensors, to guarantee the test results reliable and accurate.

- Multiple industrial pump gas sampling, ten grades of pumping flow rate for selection.

- Multi-display mode is switchable.

- Various gas concentration units can be shifted freely.

- Modular internal structure (can be customized for 1-18 gases detection)

- With an indepedent SD memory card, can view and delet the historical detection data.

- High capacity rechargeable lithium polymer battery, long operation time and standby time

- 3.5-inch hd LCD screen and 120 degree wide view, beautiful and useful menu interface