Servo motors are widely used in various applications for their precision and accuracy in controlling angular or linear position, velocity, and acceleration. Like any other electrical or mechanical component, servo motors can experience faults and errors. Here are some common servo motor faults, errors, and troubleshooting tips.

Tag: servo motor

In the transmission stage of various instruments and meters, the combination of a servo motor and reducer is widely used. This reducer is suitable for CNC processing machine tools, lathes and milling machines, various packaging machinery, food machinery, etc. It has the characteristics of high torque and wear resistance.

The linear servo motor is a modular product integrating servo motor and screw, the electric linear servo motor converting the rotary motion of servo motor into linear motion, while converting the best advantages of servo motor - precise speed control, precise rpm control and precise torque control into precise speed control, precise position control and precise thrust control; a new revolutionary product that realizes high precision linear motion series.

A linear servo motor changes the rotational motion of a motor into a straight line. Conventional electric motors move in a circle, while linear actuators move forward and backward. The push and pull action allows the device to slide, tip, and lift items with the push of a button. The design provides operators accurate and precise control over the production. The fluid movement means the linear actuator requires minimal maintenance over its lifespan and comes with natural energy efficiency. They are easier to install than their hydraulic or pneumatic counterparts, cost less, and take up significantly less room.

A linear servo motor is a modular product that integrates servo motor and lead screw, linear servo actuator is a direct drive solution where the load is directly connected to the moving portion of the motor. Direct drive linear motors are available in a variety of configurations (iron core, U-channel, tubular) but ultimately work the same.

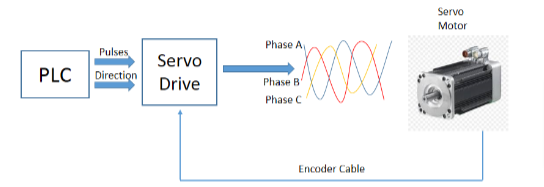

The servo driver is a controller used to control the servo motor. Its function is similar to the frequency converter. It is used for ordinary AC motors. It is a part of the servo system and is mainly used in high-precision positioning systems. Generally, the servo motor is controlled by three methods of position, speed and torque to achieve high-precision positioning of the transmission system. In order to ensure the normal operation of the equipment, it has become a very important task to judge the fault in time and deal with it in time. Here we will introduce the analysis and troubleshooting of the AC servo motor driver.

AC Servo drive is a controller used to control servo motors. Today, more and more users have it. ATO AC servo drives are widely used in automation equipment such as industrial robots and CNC machining centers. The following introduces how to install and wire the AC servo drive correctly.

Linear servo motors, also called permanent magnet linear servo motors, generate thrust and speed based on supply current and voltage, and perform linear motion along the driven axis. A linear servo motor is an integral part of a closed-loop system, providing thrust and speed based on commands from the servo controller using a feedback device to achieve a closed-loop.

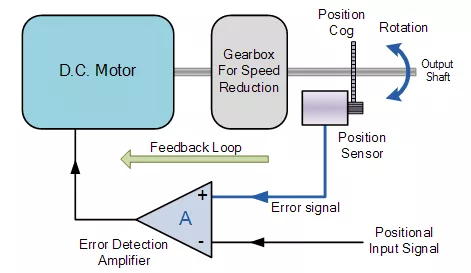

The servo motor can control the speed with accurate position. The voltage signal can be converted into torque and speed to drive the control object. The rotor speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, it is used as an executive element, and has the characteristics of small electromechanical time constant and high linearity. Servo motor is divided into DC and AC servo motor. Its main feature is that when the signal voltage is zero, there is no rotation phenomenon, and the speed decreases uniformly with the increase of torque. Now we will talk about using computer to control a DC servo motor.

The DC servo motor has many advantages, including low cost, simple structure, large starting torque, wide speed regulation range and easy control. It is easy to maintain (replacement of carbon brushes) and it has requirements for the environment. Therefore, it can be used in general industrial and civil occasions. Next we'll look at how to control DC servo motor speed with analog.

The position control mode of the servo motor is very common in the precision movement of industrial automation. The principle is that the servo motor drive carries out precise control of the motor movement after receiving the position pulse and direction pulse of the pulse generator (PLC, single chip microcomputer). Servo motor has three control modes: speed control, position control and torque control. This time we will introduce the position control mode of ATO new servo motor, using PLC to pulse.

Servo motor can control speed, position accuracy is very accurate. It can convert voltage signals into torque and speed to drive control objects. Servo motor rotor speed is controlled by the input signal, and can respond quickly, in the automatic control system, used as an executive element, and has the characteristics of mechanical and electrical time constant is small, high linearity, can receive the electrical signal into the motor shaft angular displacement or angular velocity output.

RC servo motor, short for radio control servo motor, can also be regarded as a DC servo motor, but its characteristics and application fields are different from DC servo motors. RC servo motors are mostly used for steering control of remote control models. Potentiometers (variable resistors) are used to detect the position, and the rotation angle can reach 180°.

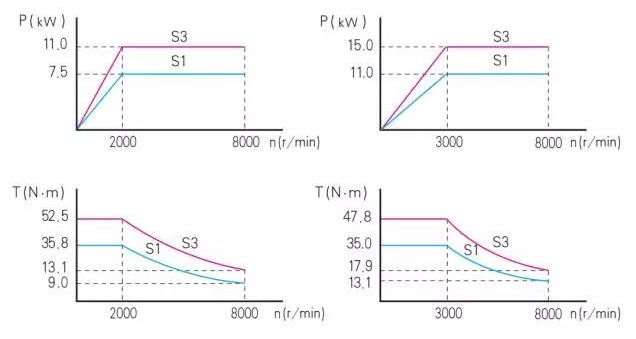

In terms of usage, the servo motor is mainly responsible for the feed of the machine tool, making the workpiece move to the tool or the tool move to the workpiece, mainly to realize the work of cutting, with higher requirements for torque and control accuracy; while the spindle motor is mainly responsible for driving the spindle of the machine tool, driving the workpiece or the tool head to rotate, with higher requirements for constant power characteristic output to meet the sufficient torque output capability at different speeds. Therefore, when designing, these two motors will make targeted parameter optimization according to their application requirements respectively.

Speed control is generally achieved by inverters, servo motors to do speed control, is generally used for rapid acceleration and deceleration or speed precision control occasions, because relative to the inverter, servo motors can reach thousands of revolutions within a few millimeters, because the servo is closed-loop, the speed is very stable. Torque control is mainly to control the output torque of the servo motor, again because of the fast response of the servo motor. Application of the above two kinds of control, you can treat the servo drive as a frequency converter, generally with analog control.

In industrial applications such as automation technology, servo motor is the most commonly used high-tech equipment. Servo motor can control speed and position accuracy, also can convert voltage signals into torque and speed to drive control objects. Servo motor is divided into AC servo and DC servo two categories.

In the servo system, the engine that controls the operation of mechanical components is called servo motor, which is a kind of subsidized motor indirect variable speed device that can control the speed, so that the position of the object and the orientation, state and other output controlled quantities can follow the input target (or a given value) of any change, and the position accuracy of the servo motor is very high, and it can convert the voltage signal into torque and speed to drive the control object, but how does a servo motor control work?

No matter what kind of servo motor, use for a long time, will produce some small problems, then today we bring you six common motor failure performances. When the servo motor has small problems, not only to detect promptly, but also to find the cause of these failures, we can prescribe the right medicine to repair the servo motor.

Servo motor is an independent electrical device, which can rotate each part of the machine with high efficiency and precision. The output shaft of this motor can be moved to a specific angle, position, and velocity that a normal motor does not have. Servo motor adopts conventional motor and its position feedback with the sensor. Before using the servo motor, you need to know how to use it to better play its role.

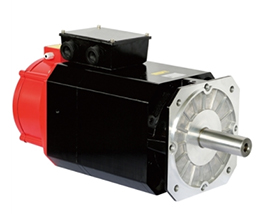

The operating principle of the AC spindle servo motor is that when the symmetrical three-phase winding on the stator is connected to the symmetrical three-phase, the excitation current is supplied by the power supply and a rotating magnetic field is established in the air gap between the stator and the rotor rotating at a synchronous speed. By the electromagnetic inductance, the induced potential is generated in the rotor guide bar. Because the rotor guide strip has formed a closed circuit, a current is running through the rotor guide strip. This generates electromagnetic torque and realizes the energy transformation from electrical energy to mechanical energy. ATO provides customers with a wide range of AC spindle servo motors of good quality with favorable prices.

|

|

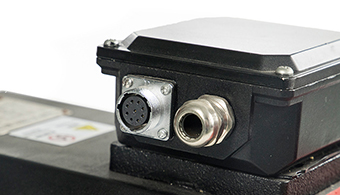

| side | compact junction box |