We are interested in knowing how to disassemble the water-cooled spindle of a CNC engraving machine to clean waterway impurities. In fact, the correct approach is not to disassemble the water-cooled spindle for cleaning, because the structure of the water-cooled spindle is quite complex, non-professionals to disassemble easy to damage the spindle, affecting the concentricity of the spindle components and parts of the connection assembly, must be disassembled to clean up, should be handed over to the manufacturer to carry out.

Tag: spindle motor

The spindle motor is a high speed, high precision mechanical and electrical precision component, we have a variety of failure phenomena in the maintenance of spindle motor process, ATO summarized in the maintenance of spindle motor common failures and what are the solutions?

The spindle motor is also called a high-speed motor, which refers to an AC motor with a rotational speed of more than 10,000 rpm/min. Mainly used in wood, aluminum, stone, hardware, glass, PVC and other industries, it has the advantages of fast speed, small size, light weight, low material consumption, low noise, low vibration, etc. It has attracted more and more attention in related industries. In the modern society with rapid technological progress, the spindle motor has been widely applied, and it couples with its meticulous workmanship, high speed and high processing quality of the motor. Besides, other ordinary motors cannot meet the technical requirements of the spindle motor or play a role as the spindle motor doe in the industrial production process.

With the development of motorized spindle manufacturing technology, there are new requirements for spindle finishing and machining efficiency, and automatic tool change technology is bred.Because of its fast and efficient tool change, it is favored by machining users today with the rising labor cost. The high-speed automatic tool change device has become an important technology of machining center and an important index of high-level machining center. ATC spindle is also becoming more and more popular.

ATO provides popular three phase 0.35kW, 9kW and 12kW air cooled automatic tool change spindle motors at a low price. Low noise 3 phase 1.5KW, 1.8kW, 4kW, 5.5kW and 7.5kW water cooled ATC spindles are also provided. It is suitable for high speed and high-precision milling, drilling and tapping of CNC planer, wood carving/engraving machine, metal and non-metallic materials.

With the development of technology and rising labor costs, more and more enterprise factories are using automation, such as machining. The ATC spindle motor is also an integral part of machining. It brings great convenience to everyone and improves production efficiency, but at the same time, there are some problems. Let's talk about some common problems and solutions of automatic tool change spindles.

With the development of industrial technology, automatic tool changing spindle is widely used. Automation has gradually become the main form of enterprise production and processing. So, what should we pay attention to in use?

- ATC spindle motors and VFD should be used together. The specifications and parameter settings of the VFD should match the rated parameters of the spindle.

- When using, first check whether the air duct is blocked or not, and use compressed air to blow through it in emergency use.

- The cooling circulation system must be in normal operation before use. Do not use without cooling

- Water cooled motors must ensure that the coolant must be clean.

It is necessary to cool and dissipate the automatic tool change electric spindle, especially in high temperature. If you find that the electric spindle is overheated during the application process, then you should consider whether to take heat dissipation measures. Do not allow the electro-spindle to run in overheating conditions, which will affect the service life. ATO will introduce to you two cooling methods for spindle motors.

With the development of industrial technology, automation has gradually become the main form of enterprise production and processing. In machining, the tool needs to be changed frequently due to different materials or shapes. The high speed motorized spindle has also been continuously developed from the traditional manual tool change to the ATC.

The rear end of the electric spindle is a cylinder structure. It uses air pressure to push the thimble against the middle pull rod so that the collet extends outward and the tool falls off, and then the device can automatically grab the tool using the shaft platform. The rear end of the spindle uses a solenoid valve to release the air and cut off the air so that the tool is clamped. This process is called automatic tool change.

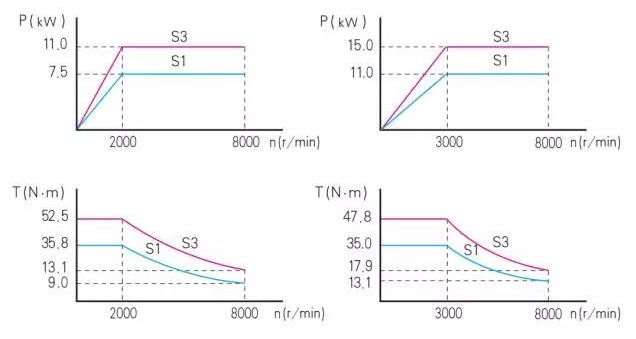

In terms of usage, the servo motor is mainly responsible for the feed of the machine tool, making the workpiece move to the tool or the tool move to the workpiece, mainly to realize the work of cutting, with higher requirements for torque and control accuracy; while the spindle motor is mainly responsible for driving the spindle of the machine tool, driving the workpiece or the tool head to rotate, with higher requirements for constant power characteristic output to meet the sufficient torque output capability at different speeds. Therefore, when designing, these two motors will make targeted parameter optimization according to their application requirements respectively.

Spindle motor, also called high speed motor, refers to the AC motor with more than 10000 rpm. Mainly used in wood, aluminum, stone, hardware, glass, PVC and other industries, it has the advantages of fast speed, small size, light weight, low material consumption, low noise, low vibration, etc.

The spindle motor is a key component of any CNC machine. Operators use it to drill, engrave, cut, and perform other such operations on materials at high speeds, and it is used in a wide variety of industries. A good spindle will ensure that the CNC machine runs efficiently and produces high-quality workpieces for you.

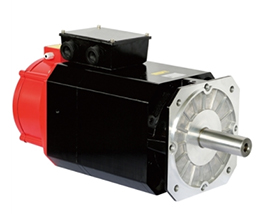

The operating principle of the AC spindle servo motor is that when the symmetrical three-phase winding on the stator is connected to the symmetrical three-phase, the excitation current is supplied by the power supply and a rotating magnetic field is established in the air gap between the stator and the rotor rotating at a synchronous speed. By the electromagnetic inductance, the induced potential is generated in the rotor guide bar. Because the rotor guide strip has formed a closed circuit, a current is running through the rotor guide strip. This generates electromagnetic torque and realizes the energy transformation from electrical energy to mechanical energy. ATO provides customers with a wide range of AC spindle servo motors of good quality with favorable prices.

|

|

| side | compact junction box |

Spindle motor is also called high speed motor, refers to the revolution more than 10000 RPM AC motor. It has the advantages of fast speed, small size, light weight, low material consumption, low noise, low vibration, widely used in wood, aluminum, stone, hardware, glass, PVC and other industries. ATO.com store provides 2 types of spindle: Air-cooled spindle motor and water-cooled spindle motor. Here we will share 11 tips with you when using a spindle motor.