Level Sensor

Industrial Capacitive Water Level Sensor, 4-20mA/RS485

Capacitance Tank Level Sensor for Oil/Gas Tank, 0-1000mm

Capacitance Fuel Level Sensor for Diesel & Petrol, 0-2000mm

Capacitive Hydraulic Oil Level Sensor, Stainless Steel

Capacitive Liquid Level Sensor for 8-11 mm Pipeline Level Detection

Capacitive Fluid Level Sensor for 12-26 mm Pipeline Level Detection

RF Capacitive Level Sensor for Corrosive/High-temp Liquids

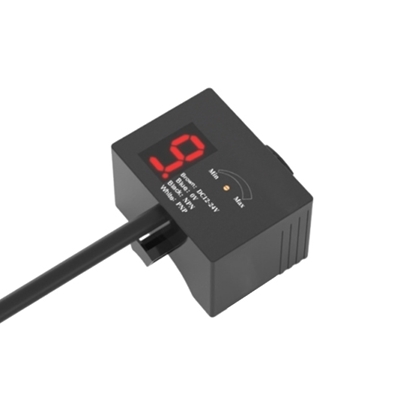

Digital Capacitance Level Transmitter, 1-1500mm

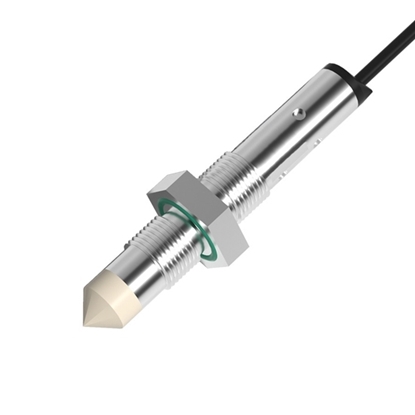

Capacitive Level Switch, Frequency Difference, G1/2"

Non Contact Capacitive Liquid Level Sensor, NPN+PNP

Contact Capacitance probe Level Sensor for Liquid/Powder

Ultrasonic Tank Level Sensor, Output 4-20mA/1-5V/RS485, 0-40M

Ultrasonic Water Tank Level Sensor, Output 4-20mA, 0~5m

Ultrasonic Liquid Level Sensor, Non Contact, 0.5-1.5M

Ultrasonic Fuel Level Sensor with Bluetooth, RS232/RS485/0-5V

Ultrasonic Oil Level Sensor, Non Contact, RS232/RS485/0-5V

Ultrasonic Level Sensor for Water/Fuel/Oil/Powder, 0-60M

Waterproof Ultrasonic Water Level Sensor, IP67, 5m~30m

Smart Wireless Ultrasonic Level Sensor, WiFi/Zigbee, 0-5m

Split-type Ultrasonic Level Sensor, Non Contact, 5m/10m/15m

What is a level sensor?

High-quality ATO level sensors is for sale, and we offer various types and functions of level sensors. A level sensor is a device used to detect and measure the height of liquid or solid materials, widely used in industries such as industrial automation, petrochemicals, water treatment, food and beverage, and pharmaceuticals. It can not only monitor the liquid level height in real time, but also detect other media such as oil, sewage, rainwater, etc., and transmit the data to the control system to achieve automation control, improve production efficiency, and prevent overflow or drying problems.

Working principle of level sensor

Level sensors detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface. Substances that flow become essentially horizontal in their containers (or other physical boundaries) because of gravity whereas most bulk solids pile at an angle of repose to a peak. Level sensors can be divided into two categories based on different measurement principles: contact type and non-contact type. Contact type level sensor: It directly contacts the liquid and other fluids measures the level through float, capacitance, conductivity, radar and other methods. For example, a float level sensor uses the float to change its electrical signal as the level rises and falls, thereby detecting the height of the level. Non contact level sensor: using technologies such as ultrasound, radar, or laser, the level can be calculated through reflected signals without direct contact with the measuring object. For example, an ultrasonic level sensor determines the level by measuring the time difference between the ultrasonic pulse from the sensor to the level.

The main types of level sensors

Level sensors are mainly divided into two types based on whether they touch the measured material:

- Contact Type: The sensor touches the liquid directly. Common examples include float, electrode, and capacitive sensors.

- Non-Contact Type: The sensor measures the level from outside, without touching the liquid. These are used in harsh or dangerous environments, like corrosive or high-temperature liquids.

Common Contact-Type Level Sensors

- Float Type (Float level sensor): A float rises or falls with the liquid level, triggering a switch. Simple and widely used in water or oil tanks.

- Conductive Type (Electrode level sensor): Uses the conductivity of the liquid to complete a circuit between electrodes. Best for water or other conductive fluids.

- Capacitive Type (Capacitive level sensor): Detects changes in capacitance caused by the liquid level. Works well with various liquids, including corrosive ones.

- Optical (Photoelectric) Type: Uses light refraction or reflection to detect if liquid is present. Good for small tanks or precision needs.

Common Non-Contact Level Sensors

- Ultrasonic Level Sensor: Emits ultrasonic waves and measures the echo time to determine the level. Ideal for water, chemicals, or bulk solids.

- Radar Level Sensor: Sends microwave or radar signals to the surface and measures the return time. Suitable for extreme conditions like high temp or pressure.

- Laser Level Sensor: Uses laser beams for distance measurement. Offers very high accuracy for clear or transparent liquids.

- Magneto strictive Sensor: Uses magnetic fields and waveguides for ultra-precise and stable level detection. Common in oil, fuel, and chemical tanks.

Application areas of level sensors

- Water treatment industry: Used for water level monitoring of water tanks, water pools, sewage treatment, etc.

- Petrochemical industry: Monitor the liquid level of oil tanks and chemical storage tanks to prevent overflow or drying up.

- Food and pharmaceuticals: Ensure precise control of liquid raw materials during the production process to improve product quality.

- Industrial manufacturing: Used for level detection on automated production lines to improve production efficiency.

- Agricultural irrigation: Used for water level monitoring and automated control of irrigation systems.

Level sensors play a crucial role in modern industry and daily life, improving production efficiency, reducing costs, and ensuring safe operation. Choosing the appropriate level sensor based on specific application requirements will help achieve more accurate level monitoring and intelligent control. If you have any questions about purchasing, you can contact us.