How to Choose a Suitable DC Servo Motor with Gearbox?

In the transmission stage of various instruments and meters, the combination of a servo motor and reducer is widely used. This reducer is suitable for CNC processing machine tools, lathes and milling machines, various packaging machinery, food machinery, etc. It has the characteristics of high torque and wear resistance. Do you know how to match the gearbox according to the servo motor in practical application?

What is a DC servo motor?

A Low-voltage DC servo motor refers to the engine that controls the operation of mechanical components in the servo system and is a device that assists in the indirect speed change of the motor. The main function of the servo motor is used in a closed loop to transmit signals to the system at any time, and at the same time correct its own operation with the signals given by the system. The low-voltage DC servo motor includes a stator, a rotor core, a motor shaft, a motor winding commutator, a motor winding, speed-measuring motor winding, and a speed-measuring motor commutator. The rotor core is laminated and fixed on the motor shaft by silicon steel punching sheets. composition. Low-voltage DC servo motors have good speed control characteristics, can achieve smooth control in the entire speed range, have almost no oscillation, are small in size, energy saving, low noise, no heat, and long life.

What is a gearbox?

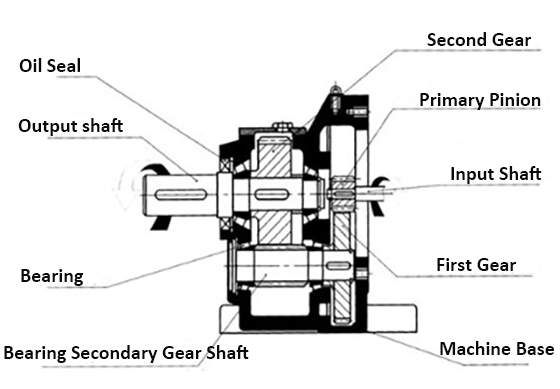

The planetary speed reducer gearbox uses all levels of gear transmission to achieve the purpose of speed reduction. The gearbox is composed of various levels of gear. The reducer is generally used for low-speed and high-torque transmission equipment. The motor, internal combustion engine, or other high-speed operating power passes through the inline planetary speed reducer gearbox. The gear on the input shaft meshes with the large gear on the output shaft to achieve the purpose of deceleration. The reducer is a power transmission mechanism that uses the speed converter of the gear to reduce the number of revolutions of the motor to the desired number of revolutions and obtain a larger torque mechanism.

How to match the gearbox according to the servo motor?

- Flange specifications: The cross-sectional size of the reducer is generally similar to that of the motor. For other parameters, refer to the instructions of the selected brand. The technical catalog generally indicates the selection steps and calculation examples. Specific models have different representations for each brand. It is usually expressed roughly by the size of the output flange or the size of the cross-section. Generally, there are 40 flanges, 60 flanges, 80 flanges, 120 flanges, 160 flanges, 18 flanges and other specifications.

- Speed ratio: The reduction ratio of the gearbox is roughly selected by dividing the rated speed of the motor by the output speed. For example, if the required output speed is 200RPM, and the rated speed of the motor is 3000RPM, then the speed ratio of the reducer is preferably about 1:15. The level of output speed depends on the needs of working conditions.

- Torque: The rated torque of the reducer must be greater than or equal to the product of the rated torque of the motor multiplied by the reduction ratio. Assuming that the rated torque of the motor is 10Nm and the reduction ratio is 15, the rated torque of the selected gearbox model should be greater than 10*15=150Nm.

- Accuracy: The return clearance (backlash, backlash, or gyration clearance) of the gearbox depends on the specific work requirements. Generally speaking, the clearance used with the servo motor should not be greater than 20arc/min.

General principles:

- Small servo motors can be equipped with large reducers, but large motors are generally not equipped with small reducers.

- The higher the rigidity of the same specification, the better the quality, so our process is a hard-tooth surface-cutting process.