Dryer

Industrial/Lab Vacuum Oven with Pump

Freestanding Electric Oven, Forced Air, 220V/110V

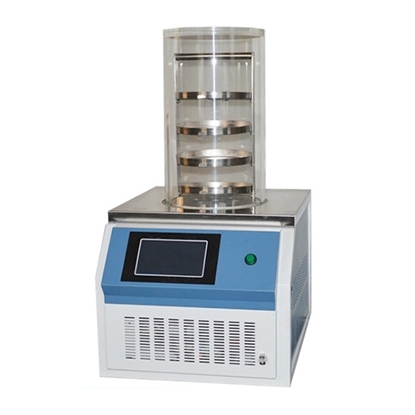

Ordinary/Gland Type Vacuum Freeze Dryer Machine

Multi-Manifold Industrial/Commercial Freeze Dryer

Dryer is an industrial, commercial, and laboratory equipment used in drying process of materials. ATO offers industrial vacuum oven with pump and electric forced air oven, specially designed for drying heat sensitive, easily decomposed and easily oxidized substances. Freeze dryer is available in ordinary type, gland type and multi-manifold type. The all dryers are freestanding, with desktop and vertical design, and a variety of capacities and power options. It is ideal for drying, baking and heating materials.

How to Maintain a Dryer?

Anti-corrosion. For dryers that often handle corrosive materials, we must do a good job of anti-corrosion work. The commonly used anti-corrosion methods mainly include the following three:

- Electrostatic powder spraying method. The electrostatic powder spraying method is a method of applying a new type of powder coating to the cylinder of the dryer. When we manufacture our dryers, we usually use cold-rolled stainless steel. The cost of this kind of steel is very high, and it cannot have superior corrosion resistance when replaced with ordinary carbon steel. The corrosion resistance of the powder coating used in electrostatic powder spraying is completely comparable to that of stainless steel. Moreover, this kind of powder coating has the characteristics of toughness, durability, good decoration, outdoor weather resistance and heat resistance.

- Use austenitic nickel-chromium stainless steel for welding. There are many parts of the dryer that must be welded, and the materials used in the old-fashioned welding often appear cracks and corrosion. The impact on the life of the freeze dryer machine is extremely serious. The difference between austenitic nickel-chromium stainless steel and ordinary carbon steel lies in its poor thermal conductivity, large expansion coefficient during heating, and high electrical resistance.

- Passivation and phosphating method. In the manufacturing and production of dryers, many parts are made of carbon steel. If the working time is long, it is easy to cause a lot of rust on the surface, and a lot of manual rust removal work is often required. Passivation and phosphating methods are mainly through electrical and electrochemical reactions. Through a one-time treatment, the surface of the rust-grown iron and steel workpiece can show the original color of the metal, and at the same time, a dense anti-rust film layer is formed on the metal surface.

Fault Checking. If you want to maintain the freeze dryer, you need to check and judge the failure of the dryer as much as possible to use visual, auditory, and olfactory tests to analyze:

- Use visual judgment. The so-called visual judgment is to observe the changes in the readings of the various meters of the industrial freeze dryer, the conditions of each connecting part, the leakage of each joint sealing surface, whether there are abnormalities in the oil and water, and the heating of the motor.

- Use auditory judgment. The so-called use of auditory judgment is to listen to whether the sound emitted by the components of the lab freeze dryer is normal, and if there is an abnormal phenomenon, it is necessary to determine the source of the abnormal sound.

- Use smell to judge. The so-called olfactory judgment is to use the nose to smell the various parts of the dryer and the oil at the parts for abnormal odors.

Dryer FAQs:

What is freeze drying?

Freeze drying takes advantage of the scientific principle of "sublimation", the direct transition of a solid to a gas, by removing ice from frozen food as water vapor. Using sublimation, the food retains much of its original texture, flavor, and nutrition when rehydrated. Once frozen, foods are subjected to vacuum drying. The air and water vapor are removed from the food processing chamber using a vacuum pump. This includes removing the water vapor that was once inside of the foods. When these two steps are properly completed, the food is dry enough to allow for safe storage at room temperature.

What happens to microorganisms in the freeze-drying process?

Nothing. The microorganisms stay viable, but dormant, even under the extreme conditions of freeze drying. In fact, scientists use a laboratory version of freeze drying to preserve microorganisms for future studies because the microorganisms can be rehydrated alive for decades. Therefore, when home freeze drying raw foods the microorganisms on those raw foods will remain viable, then activate upon rehydration. Food items that are traditionally cooked before eating must also be cooked before eating as a freeze-dried food. Examples are raw meats, raw seafood, raw eggs, and foods containing these raw ingredients.

Can freeze dried foods be safely vacuum packaged?

Yes. As long as the food is dried to a low residual moisture, vacuum packaging is safe. Remember, vacuum packaging is not a food safety process itself. In fact, removing oxygen from a package may make it more of a concern for the botulism bacteria to grow and produce toxin if there is a moist environment. Fortunately, without moisture the botulism bacteria cannot grow. Therefore, it is safe to place properly dried or freeze-dried foods in vacuum packaging or in containers that also have oxygen absorber packets placed inside.