Hello everyone,

I have a question about the shaft orientation of the ATO-DYN-205 torque sensor during testing.

From what I can tell, one shaft seems to “drive” the other. The first shaft requires some non-zero torque just to spin, while the second shaft only registers the torque acting on it. In my quick test, gripping and spinning the first shaft doesn’t show any torque on the display, but gripping and spinning the other shaft does register torque (basically the torque needed to spin the sensor itself).

The labeling on the sensor suggests the motor should be connected to the first shaft. That makes it seem like the sensor is intended to detect the load torque, rather than the full torque produced by the motor.

My question: Is it acceptable to connect the motor to the other shaft instead?

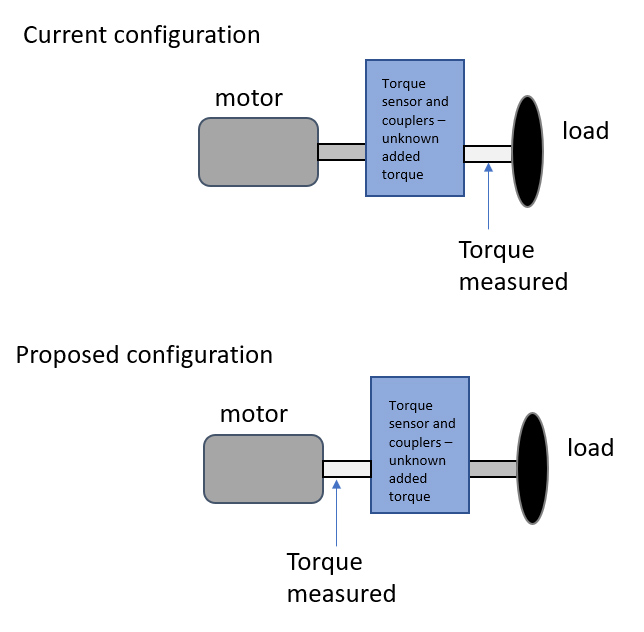

In that case, the sensor would read the full motor torque, even if it doesn’t perfectly isolate the load torque on the opposite side. I’ve added a simple illustration below to show what I mean.

This would actually work better for us, since our goal is to characterize motor performance under a known torque, not to precisely resolve the external load. Any input would be appreciated.

I have a question about the shaft orientation of the ATO-DYN-205 torque sensor during testing.

From what I can tell, one shaft seems to “drive” the other. The first shaft requires some non-zero torque just to spin, while the second shaft only registers the torque acting on it. In my quick test, gripping and spinning the first shaft doesn’t show any torque on the display, but gripping and spinning the other shaft does register torque (basically the torque needed to spin the sensor itself).

The labeling on the sensor suggests the motor should be connected to the first shaft. That makes it seem like the sensor is intended to detect the load torque, rather than the full torque produced by the motor.

My question: Is it acceptable to connect the motor to the other shaft instead?

In that case, the sensor would read the full motor torque, even if it doesn’t perfectly isolate the load torque on the opposite side. I’ve added a simple illustration below to show what I mean.

This would actually work better for us, since our goal is to characterize motor performance under a known torque, not to precisely resolve the external load. Any input would be appreciated.

0