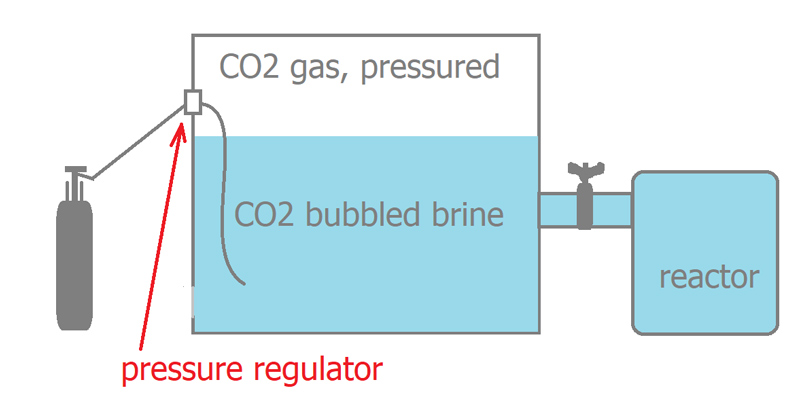

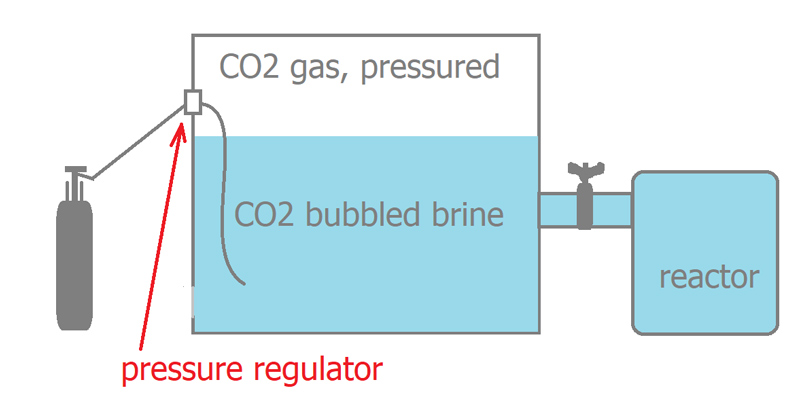

Hi, I am a Ph.D. student at a University, working in the Environmental Engineering department. I am running an experiment that consists of a 10-gallon tank filled with a specific brine (5 gallons), where CO2 is bubbled to keep a 100% CO2 atmosphere (inside the tank) with a pressure of 5 psig +/- 10%. The CO2 used to keep this pressure comes from a commercial cylinder, and the system is relieved to the atmosphere. The brine is pumped to another reactor and then returned to the original tank. I am having difficulties keeping this pressure stable. The test runs for 6 hours and demands full attention and adjustment all the time. I need to expand the test time to 24 and 48h, which makes it infeasible to operate without an automatic controller. I am using a manual pressure regulator valve to control the intake of CO2 and a back-pressure valve to control the relief of the Tank.

I was thinking about using the 1/4 Inch Electronic Air Pressure Regulator model ATO-NITV103 to replace the relief valve (back pressure valve). But I am not sure how it is going to work. I don’t know what power supply, input and output signal to use. Does it work as a controller by itself? Can I just adjust the set point for 4.5 psig and have the valve 100% closed and 5.5 psig to get the valve 100% open and let the control regulate in between these set points? Does the valve operate as a proportional valve? Is the controller proportional, too? Can I have an output signal to be read by a computer or data logger? I have a ¼” FNPT available, and the flow rate is very low (not measured).

I would appreciate your thoughts and input.

Thank you in advance for your help.

I was thinking about using the 1/4 Inch Electronic Air Pressure Regulator model ATO-NITV103 to replace the relief valve (back pressure valve). But I am not sure how it is going to work. I don’t know what power supply, input and output signal to use. Does it work as a controller by itself? Can I just adjust the set point for 4.5 psig and have the valve 100% closed and 5.5 psig to get the valve 100% open and let the control regulate in between these set points? Does the valve operate as a proportional valve? Is the controller proportional, too? Can I have an output signal to be read by a computer or data logger? I have a ¼” FNPT available, and the flow rate is very low (not measured).

I would appreciate your thoughts and input.

Thank you in advance for your help.

0