What is Pneumatic Drill?

Pneumatic Drill is a handheld pneumatic tool mainly used for drilling metal components, especially suitable for drilling on thin-walled shell components and light alloy components such as aluminum and magnesium. Air drills have the characteristics of high work efficiency and high drilling accuracy, and are widely used in home appliance manufacturing, house decoration, automobile ship manufacturing, aerospace industry manufacturing and maintenance industries. They have high power, no sparks, and high safety. Next, ATO automation will provide a detailed introduction to the types, working principles, advantages, and precautions of pneumatic drills.

Pneumatic Drill Types

There are many types of pneumatic drills, mainly divided into right angle drills, straight drills, and angle drills. Among them, right angle drills are mostly used in narrow spaces or situations with limited degrees of freedom. Straight drills are suitable for surface dressing of larger workpieces or other larger holes, while angle drills can complete the work of right angle drills and straight drills. In addition, according to the different designs of pneumatic heads, pneumatic drills can also be divided into three types: axial, angular, and hollow. Axial pneumatic drills are suitable for machining small holes and have relatively high work efficiency; Angular pneumatic drills are suitable for processing larger holes. Due to their special angle design, they can improve the posture of the human body during work and reduce work burden; Hollow pneumatic drills are commonly used in fields such as wall penetration and coal mining.

Pneumatic Drill Working principle

The core of an air drill is a pneumatic motor, which converts the compressed air capacity into the rotational kinetic energy of the motor, and then outputs it to the chuck, which is the drill bit part, through a reduction gear. Its working principle is to use pneumatic motors to convert the energy of compressed air into mechanical energy. When compressed air enters the pneumatic motor, the blades inside the pneumatic motor begin to rotate, pushing the rotor to rotate. The rotation of the rotor is transmitted to the drill bit through the gearbox, causing the drill bit to generate rotational motion and complete the drilling operation on the workpiece. During this process, pneumatic drill rigs have high work efficiency and can quickly complete drilling operations. In addition, the working principle of pneumatic drills also includes two aspects: pneumatic system and transmission system. Pneumatic system refers to a system composed of pneumatic motors, pressure control devices, and other components. Its function is to introduce compressed air into the pneumatic motor and provide a power source. The transmission system refers to a system composed of components such as a rotor, gearbox, drill bit, etc. Its function is to transmit the power generated by the pneumatic motor to the drill bit and complete the drilling operation.

Pneumatic Drill Advantages

Stable performance: Air drilling is driven by air, and compared to other driving methods, a stable air drilling system can maintain appropriate drilling parameters, such as speed, impact force, etc, ensuring that the drill bit can smoothly pass through the formation and complete drilling tasks, and the working time is long and not prone to failure.

Easy to operate: The operation of an air drill rig is relatively simple, and basic skills such as mastering the correct grip posture and controlling the working speed of the air drill can be used.

Low cost: Compared to hydraulic drills and other equipment, air drilling rigs have lower costs and more affordable maintenance costs. This external pneumatic drill bit can be used with various accessories, including drill bits, screwdriver heads, reamers, etc. This versatility enables the tool to perform various tasks beyond drilling, such as screwdrivers, grinding and chiseling.

Durability: The pneumatic drilling rig can withstand heavy usage. They are designed with sturdy components that can withstand the requirements of industrial and building environments.

Adjustable power and torque: Pneumatic drills provide adjustable power and torque settings, providing flexibility for different drilling tasks. This feature allows operators to customize the performance of tools based on the materials drilled and the desired results.High safety: Because compressed air is used as the power source, which is cold, long-term use of the machine greatly helps with heat dissipation. This is why factories prioritize air drills for long-term work. Due to the use of gas as power, it is safer and not afraid of safety hazards such as electric shock and leakage. It is also suitable for special scenarios such as flammable and explosive operations.

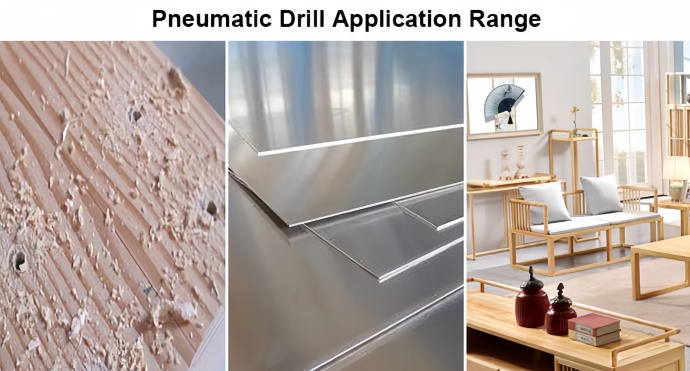

Wide application range: Pneumatic drills are suitable for drilling natural stone, concrete, fiberglass, plastic and other materials, and can also be used in industries such as mining, tunnel engineering, and construction. The efficiency and versatility of air drills can meet various home maintenance needs. They can be used to make small household items, decorations, etc, to meet the needs of personalized decoration.

Matters Needing Attention

- Before using a pneumatic drill, it is necessary to ensure that there is sufficient air in the compressed gas tank and thoroughly check whether all components of the pneumatic drill are functioning properly;

- When using drill bits, appropriate rotation speed and drill bit size should be selected, and the air flow rate should be adjusted as needed;

- When using, the drill bit should be kept perpendicular to the surface of the workpiece to avoid damage to the drill bit;

- After use, the pneumatic drill should be thoroughly cleaned and properly stored.