Limit Switch

Waterproof Limit Switch, 1NO 1NC, 3A/250VAC, 5A/125VAC

Heavy Duty Limit Switch with Roller Lever, 1NC, AC 380V

High Temperature Limit Switch with Roller Lever

High Temperature Limit Switch with Adjustable Roller Lever

High Temperature Limit Switch with Roller Plunger

High Temperature Limit Switch with Top Plunger

High Temperature Limit Switch with Coil Spring

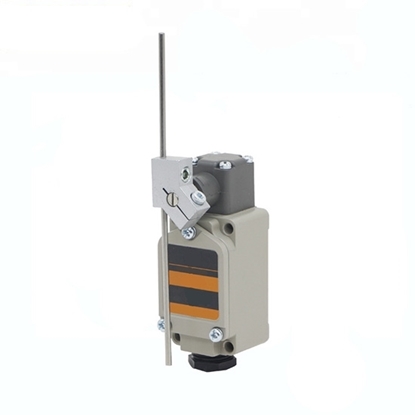

High Temperature Limit Switch with Adjustable Rod Lever

High Temperature Limit Switch with Fork Lever

Rotary Limit Switch for Crane, 380V AC/220V DC, 1 NO+1 NC

Mechanical Limit Switch with Roller Lever/Plunger, IP65 Waterproof

Micro Limit Switch, Coil Spring/Roller Lever/Plunger, 5A/250VAC

Micro Travel Limit Switch, Adjustable Rod Lever/Push Button, NO NC

Cross Rotary Limit Switch, 380V 16A, IP65, 180°/360°

Door Limit Switch, 24VDC, 1NO+1NC, IP67

Mechanical Limit Switch Box, 2-SPDT, IP67

Mini Limit Switch, Adjustable Rod Lever/Roller Lever, 6A/250VAC

Magnetic Limit Switch, NO+NC, 380VAC 8A/250VDC 5A, IP67

Explosion Proof Limit Switch, Roller Lever/Plunger, 220V/380V

Height Limit Switch for Lifting, 4 NO 4 NC, 380V 10A

Limit switch is a common small-current switch. It uses the collision of the mechanical moving parts to make their contacts make or break the control circuit, so as to achieve the purpose of mechanical control and limit protection. Usually, limit switches are used to limit the position or stroke of mechanical movement, so that the moving machinery can automatically stop, reverse movement, variable speed movement or automatic round-trip movement according to a certain position or stroke. The limit switch changes the operating state of the motor by converting the mechanical displacement into electrical signal. Therefore, limit switches are more widely used in the field of industrial automation. It can be equipped with different mechanical equipment to form more complex automation control system.

Types of Limit Switches

Limit switches can be divided into many types according to their structure, operation mode and application scenarios. The following are the main classification methods:

Mechanical limit switch

- Mechanical limit switches rely on physical contact to trigger, and are commonly used in automation equipment and mechanical devices.

- Rotary Lever Type: A lever with a roller, which can be pushed by the movement of an object to trigger the switch, suitable for linear or rotary motion detection.

- Plunger Type: The top of the switch has a press-type plunger. When the object touches and presses the plunger, the switch is triggered. It is suitable for short-distance precision detection.

- Ball Plunger Type: The end of the plunger has a ball to reduce friction and improve durability. It is suitable for high-frequency use scenarios.

- Fork Lever Type: There are two lever arms, suitable for bidirectional operation, and can detect movement in both positive and negative directions.

Non-contact limit switch

- Non-contact limit switch relies on induction technology to detect objects, does not require direct contact, and is suitable for scenarios that require high precision or avoid mechanical wear.

- Photoelectric Limit Switch: Uses infrared or laser to detect objects, suitable for high-speed or high-precision detection, such as packaging lines.

- Magnetic Limit Switch: Triggered by magnetic field induction, commonly used in access control, liquid level detection and other scenarios.

- Inductive Limit Switch: Generates induction signals for metal objects, commonly used in automation equipment, such as CNC machine tools.

- Capacitive Limit Switch: Can detect metal and non-metal objects, such as liquids, particles, powders, etc., suitable for food processing and chemical industries.

Classification by reset method

- Automatic Reset: When the object leaves the trigger position, the switch automatically returns to its initial state. For example, a temperature control switch will automatically reset after the temperature drops.

- Manual Reset: It will not automatically recover after being triggered, and the reset button must be pressed manually to recover, such as some safety protection switches.

Classification by application environment

- General Type: Applicable to general industrial machinery or automation equipment.

- High Temperature Type: Designed for high temperature environments, such as boilers, ovens, etc.

- Waterproof Type: Applicable to humid or underwater environments, such as food processing equipment or outdoor machinery.

- Explosion-proof Type: Used in flammable and explosive environments, such as chemical plants and mines, to prevent sparks from causing danger.

- Different types of limit switches are suitable for different industrial application scenarios. If you need a specific type of product recommendation, you can provide specific application requirements.

What are the Application of Limit Switch?

Limit switches play a key role in industrial automation and manufacturing, and are widely used to detect the position of mechanical parts, control conveyor belt operation, and ensure the precise operation of automated equipment. For example, in robots and CNC machine tools, limit switches can prevent overtravel and improve production accuracy and safety. In addition, in logistics and warehousing systems, it is used in sorting, handling and lifting equipment to ensure the correct transmission and storage of materials.

In terms of safety systems and equipment control, limit switches are used for elevator floor detection, emergency stop devices, and access control security control. In the transportation field, it is used in vehicle door detection, railway track switching, automatic parking systems, etc. to improve operational safety. In HVAC (heating, ventilation and air conditioning) and temperature control systems, limit switches can monitor the temperature of fans, valves and boilers to ensure that the equipment operates within a safe range.

Limit switches also play an important role in household appliances, agriculture and heavy equipment. For example, washing machines, microwave ovens and vending machines use limit switches to detect whether the door is fully closed; agricultural machinery and engineering equipment use limit switches to detect the position of arms and buckets to ensure the safe operation of equipment. Due to their high reliability and durability, limit switches have become indispensable control components in many industries.