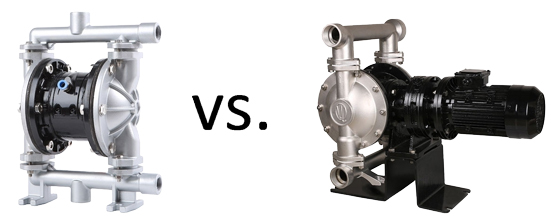

Air Diaphragm Pump vs. Electric Diaphragm Pump

Diaphragm pump is divided into air powered diaphragm pump and electric operated diaphragm pump. Pneumatic diaphragm pump is a new type of conveying product that uses compressed air as the power source. It can absorb all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. Material is available in aluminum alloy, stainless steel, non-metallic and cast iron. Electric diaphragm pump is also a new type of pump, which is used in petrochemical, ceramics, metallurgy and other industries. There is no need to irrigate and divert water, and the self-priming ability is strong. It directly separates the conveyed medium from the transmission mechanical parts, so the medium will never leak to the outside. However, what is the difference between an air diaphragm pump and an electric diaphragm pump?

- Different driving methods. The air operated double diaphragm pump is driven by compressed air (2-8.4 kg air pressure), and the electric diaphragm pump is driven by electricity.

- Different flow parameters. The maximum flow rate of the air operated diaphragm pump is 60m/h, and the flow rate of the electric diaphragm pump is only 28m/h.

- Different adjustments. The pneumatic diaphragm pump can adjust the flow rate directly by adjusting the air source pressure. The electric diaphragm pump just can adjust the flow rate with a frequency converter.

- Air diaphragm pumps are structural explosion-proof, which is suitable in all kinds of flammable and explosive places, while electric diaphragm pumps must be equipped with an explosion-proof motor to meet explosion-proof requirements.

- The outlet of the AODD pump can be held back, but the outlet of the electric diaphragm pump cannot be held back, and a safety valve or a pressure relief valve must be installed.

- Under the same model, the air diaphragm pump is cheaper and lighter than the electrical diaphragm pump.

ATO air operated diaphragm pump features

- It will not overheat. It is a process of expansion and heat absorption when exhausting. When the pneumatic pump is working, the temperature is reduced, and no harmful gas is discharged.

- No sparks will be produced. The pneumatic diaphragm pump does not use electricity as power, and prevents static sparks after grounding.

- AODD pump can pump particle-containing liquid. Because the positive displacement works and the inlet is a ball valve, it is not easy to be blocked.

- The shear force for the material is extremely low. When working, the pump spits out as it sucks in, so the agitation of the material is minimal, and it is suitable for the transportation of unstable.

- It has the function of self-priming.

- It can do diving work.

- The fluid that can be transported is extremely wide, from low viscosity to high viscosity, from corrosive to viscous.

- Small size, light weight, easy to move.

- No lubrication is required, easy to maintain, and the working environment will not be polluted due to dripping.

- The air diaphragm pump can always maintain high efficiency and will not be reduced due to wear.

- 100% energy utilization. When the outlet is closed, the pump automatically stops.

- No dynamic seal, easy maintenance to avoid leakage.

ATO electric diaphragm pump features

- No need to irrigate and divert water, and the self-priming capacity is more than 7 meters.

- With good passing performance, particles and mud with a diameter of less than 10 mm can pass through effortlessly.

- Since the diaphragm separates the conveyed medium from the transmission mechanical parts, the medium will never leak outward. And the pump itself has no shaft seal, and the service life is greatly extended. According to different media, the diaphragm is divided into neoprene, fluororubber, nitrile rubber, etc., which can fully meet the requirements of different users.

- Small size and light weight. Due to the planetary cycloid transmission structure, the pump type is small in size. Compared with the same type of pump, its volume and weight are reduced by about half.

ATO offers 3/8 inch, 1/2 inch, 3/4 inch, 1 inch, 1-1/2 inch, 2 inch, 3 inch 4 inch, and 5 inch air and electric diaphragm pumps for you, shop online now!