Diaphragm Pump vs. Peristaltic Pump

Both styles have their own advantages and disadvantages. While today's diaphragm pumps are more complex than they were a few years ago, with better valves, diaphragms, drive mechanisms, etc, they still require a basic understanding of a successful procedure. On the other hand, peristaltic pumps are simpler to use initially and require less experience to operate under adverse conditions. In this article, we will compare diaphragm pump and peristaltic pump.

Definition:

Peristaltic pumps or also known as chemical feed pumps refer to the way liquid is moved from one part to another. The word peristalsis means frequent compression and release. Here, this means that frequent compression and release of the tubing creates a pressure differential that allows the 3V portable peristaltic pump to deliver the liquid.

A diaphragm pump, also known as a membrane pump, is a positive displacement pump that utilizes a rubber, thermoplastic or teflon diaphragm and suitable valves on either side of the diaphragm (check valve, butterfly valve, flap valve or any other form of globe valve) in combination with the reciprocating action to pump out the liquid.

Working Principle:

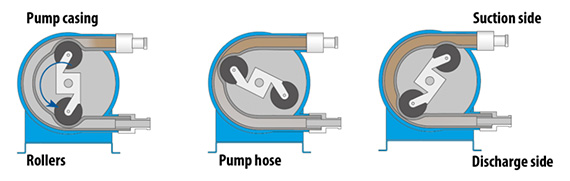

The basic principle on which 12V peristaltic pumps work is to transport liquid from one point to another by creating a pressure differential. As shown in the picture, when the triangular rotor of the pump is connected with the shaft of the motor. When the motor is powered, it spins the triangular rotor.

The triangular rotor of the high precision peristaltic pump compresses the hose. At the top of the triangular rotor, there is an arrangement so that when the rotor comes into contact with the hose pipe, it compresses and releases the pipe. This effect can be called peristalsis. During this movement, the liquid within the hose is propelled forward. Accurately control the speed of the shaft and avoid air gaps in the liquid.

Diaphragm pumps work as simple as two valves use air pressure to force a piston back and forth to open and close, but also as complex as delicately balanced vanes turn on air. Using an air motor on this type of pump allows it to be used in multiple applications. The air motor can be made small and light, ideal for use as a portable pump. As a submersible pump, the use of air makes it a sealed unit with no external moving parts.

Application:

Peristaltic pumps have a variety of uses. It is mainly used in the medical field and laboratory applications. In medical applications, blood can be transferred from one part to another. This is very useful during procedures like dialysis. In laboratory applications, such as chemical laboratories, it is used as a chemical feed. Also, it is used to fill different containers with chemicals.

Other medical applications include pumping IV fluids through infusion sets, other fluids that must be strictly avoided from cross contamination, corrosive chemicals, etc. They are also used in critical surgeries. Besides medical and laboratory applications, they are also used in agricultural applications to pump large amounts of water. It is also suitable for inducing the effects of some pesticides on crops. Also used for pumping abrasive and viscous fluids.

The applications of diaphragm pump commonly applicable in many industries. These pumps are used to push liquids like corrosive chemical, volatile solvents, viscous, shear-sensitive foodstuffs, pharma product, sticky fluids, dirty water, smaller solids, creams, abrasive slurry, oils, and gels.