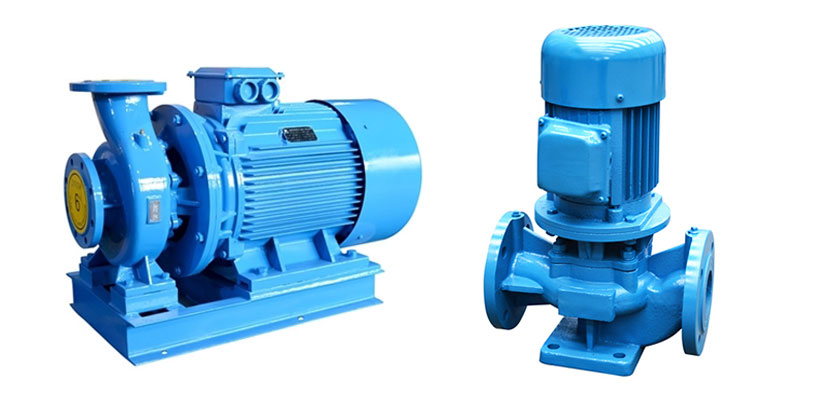

Horizontal Centrifugal Pump vs. Vertical Centrifugal Pump

A Centrifugal pump refers to a pump that transports liquid by the centrifugal force generated by the rotation of the impeller. Centrifugal pumps work by rotating the impeller to make the water centrifugally move. Before the pump is started, the pump casing and the suction pipe must be filled with water, and then the motor is started so that the pump shaft drives the impeller and the water to rotate at a high speed. into the pressurized water line of the pump.

We all know vertical centrifugal pumps and horizontal centrifugal pumps, both of which are centrifugal pumps. It can be used in everyone's daily life. So what is the difference between these two pumps? And what are the differences? For this issue, ATO.com will give you a brief explanation so that you can have a more detailed understanding of these two pumps.

Difference between the two centrifugal pumps

Structure

We know from their names and obvious that one is a centrifugal pump with a vertical structure, and the other is a centrifugal pump with a horizontal structure.

Functions

- Vertical centrifugal pump: It is mainly used to transport clean water and other liquids with physical and chemical properties (similar to clean water), used for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire pressurization, long-distance transportation, HVAC Refrigeration cycle, bathroom and other cold and warm water cycle pressurization and equipment. The operating temperature is <80℃.

- Horizontal centrifugal pump: It is used to transport liquids that do not contain solid particles, are corrosive and have a viscosity similar to water. Its operating temperature is -20°C to 120°C.

Connection Type

The vertical pump is a bottom-up superimposed connection form, and the horizontal pump is longitudinally arranged on the left and right and on the base.

Space

Since the vertical centrifugal pump is a vertical structure, the vertical pump does not require much space in terms of floor space. The horizontal centrifugal pump has a much larger footprint than a vertical pump due to its horizontal structure.

Installation form

The two different structures, vertical and horizontal, also make their installations different. For example, the vertical pump is integrally connected, and the installation is very simple. The horizontal pump also needs to be adjusted for accuracy after installation.

Maintenance

The maintenance of the vertical pump is difficult. For example, the upper part of the impeller needs to be removed before it can be carried out. The horizontal pump is relatively easy, as long as the inlet pipe is removed, the impeller can be overhauled.

These two centrifugal pumps have their own advantages, and users can buy them according to their needs. ATO 1 hp to 100 hp single-stage vertical centrifugal pump and horizontal centrifugal pump for sale, which are suitable for different purposes. Welcome to the ATO website for purchase.