What is a Centrifugal Pump?

A centrifugal pump is a mechanical device designed to move fluid by transferring rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly rotating impeller along its axis and exits through the impeller's blade tips along its circumference by centrifugal force. The action of the impeller increases the velocity and pressure of the fluid and directs it towards the pump outlet. The pump casing is specially designed to compress the fluid from the pump inlet, direct it to the impeller, and then slow and control the fluid before discharging.

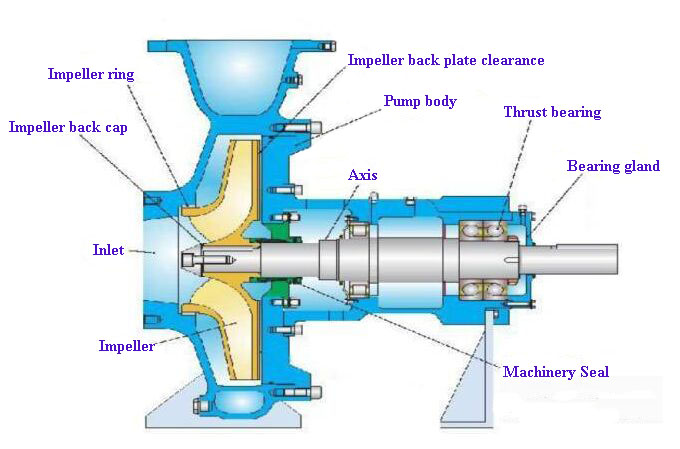

Basic structure of centrifugal pump

The main components of the stainless steel centrifugal pump include: impeller, pump shaft, pump casing, pump seat, stuffing box (shaft seal device), leakage reducing ring, bearing seat, etc.

- The impeller is the core part of the centrifugal pump. It has a high speed and a large output force.

- The pump body is also called the pump casing, which is the main body of the pump. It plays the role of supporting and fixing, and is connected with the bracket on which the bearing is installed.

- The function of the pump shaft is to connect the motor with the coupling and transmit the torque of the motor to the impeller, so it is the main component for transmitting mechanical energy.

- The sealing ring is also called the leakage reducing ring.

- The stuffing box is mainly made of stuffing, so that the water flow in the pump does not flow to the outside and the outside air does not enter the pump. Always maintain a vacuum inside the pump! When the friction between the pump shaft and the packing generates heat, the water seal pipe is used to inject water into the water seal ring to cool the packing!

- Axial force balance device. During the operation of the centrifugal pump, since the liquid enters the impeller under low pressure and flows out under high pressure, the pressure on both sides of the impeller is unequal, resulting in an axial thrust directed towards the inlet. It will cause axial movement of the rotor, resulting in wear and vibration, so an axial thrust bearing should be installed to balance the axial force.

Advantages of centrifugal pump

- Compact structure.

- Wide range Wide range of flow and head.

- Suitable for mildly corrosive liquids.

- Various control options.

- Uniform flow, stable operation and low vibration. No special shock-absorbing foundation is required.

- Equipment installation, maintenance and repair costs are low.

Application of centrifugal pump

- liquid delivery

- cooling system

- Industrial Cleaning System

- aquaculture farm

- Fertilizer system

- Metering system

- Industrial equipment

Centrifugal pumps can be widely used in electric power, metallurgy, coal, building materials and other industries to transport slurries containing solid particles. Such as hydraulic ash removal in thermal power plants, slurry transportation in metallurgical concentrators, coal slurry and heavy medium transportation in coal washing plants, etc. When the centrifugal pump is working, the pump needs to be placed on land, the suction pipe is placed in the water, and the pump needs to be started. Due to the limitation of the structure of the mud pump and the submerged centrifugal pump, the motor needs to be placed on the water surface and the pump is put into the water, so it must be fixed, otherwise, the motor will be scrapped when it falls into the water.