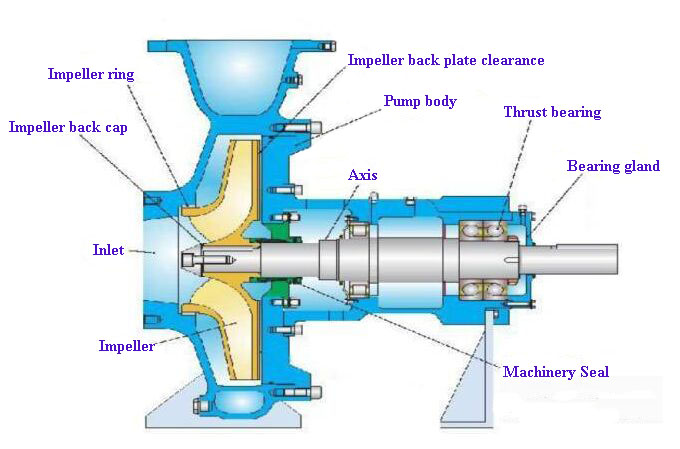

What are Parts & Functions of a Centrifugal Water Pump?

Centrifugal water pumps are widely used in electric power production, because of their wide range of performance (including flow, pressure head and loss of media properties), small size, simple structure, easy operation, uniform flow, long life, Prominent advantages such as lower acquisition costs and lower operating costs. There are many varieties of centrifugal pumps. Although the structures of various types of pumps are different, the main components are basically the same. The main components of the centrifugal water pump include: impeller, pump shaft, pump casing, pump seat, stuffing box (shaft seal device), leakage reducing ring, bearing seat, etc.

Impeller

The impeller is the working part of the centrifugal water pump. It relies on its high-speed rotation to perform work on the liquid to realize the transportation of the liquid. It is an important part of the centrifugal pump.

The impeller is generally composed of three parts: the wheel hub, the blade and the cover plate. The cover of the impeller is divided into a front cover and a rear cover. The cover on the side of the impeller port is called the front cover, and the cover on the other side is called the rear cover.

When the centrifugal pump is started, the pump shaft drives the impeller to rotate at a high speed, forcing the liquid pre-filled between the blades to rotate. Under the action of inertial centrifugal force, the liquid moves radially from the center of the impeller to the outer circumference.

The liquid obtains energy during the movement of the impeller, the static pressure energy increases, and the flow rate increases. When the liquid leaves the impeller and enters the pump casing, it decelerates due to the gradual expansion of the flow passage in the casing, and part of the kinetic energy is converted into static pressure energy, and finally flows into the discharge pipeline along the tangential direction.

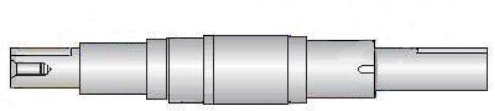

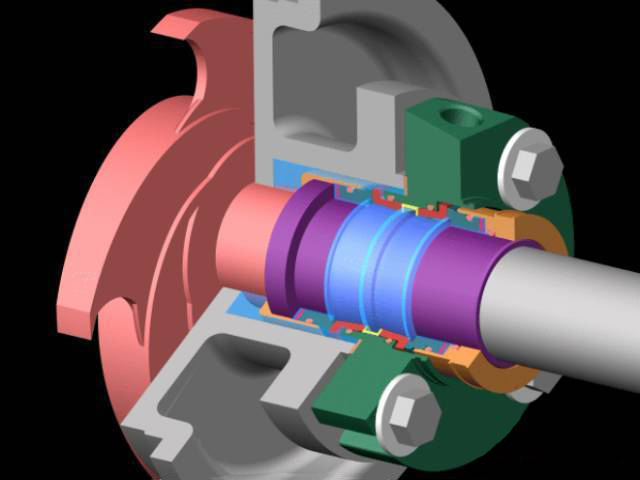

Pump shaft

The main function of the pump shaft of the centrifugal water pump is to transmit power, and the supporting impeller is kept in the working position to operate normally. One end of the shaft is connected to the motor shaft through a coupling, and the other end supports the impeller for rotational movement. The shaft is equipped with components such as bearings and axial seals.

Common materials for pump shafts are carbon steel and stainless steel.

The impeller and the shaft are connected by a key. Since this connection method can only transmit torque and cannot fix the axial position of the impeller, a shaft sleeve and a locking nut are also used in the water pump to fix the axial position of the impeller.

After the impeller is axially positioned with the locking nut and the shaft sleeve, in order to prevent the locking nut from unbuckling, it is necessary to prevent the water pump from reversing.

Bushing

The function of the shaft sleeve is to protect the pump shaft, so that the friction between the packing and the pump shaft is transformed into the friction between the packing and the shaft sleeve, so the shaft sleeve is an easy-to-wear part of the centrifugal pump.

The surface of the shaft sleeve can also generally be treated by carburizing, nitriding, chrome plating, spraying and other treatment methods. The surface roughness requirements generally reach Ra3.2μm-Ra0.8μm. It can reduce the friction coefficient and improve the service life.

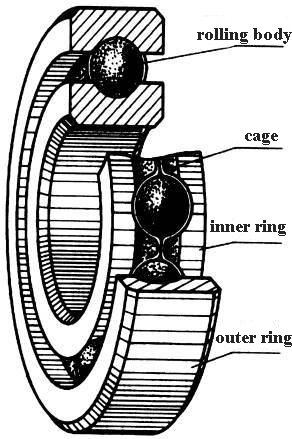

Bearing

The bearing plays the role of supporting the weight and bearing force of the rotor. Rolling bearings are mostly used in centrifugal pumps. The outer ring and bearing seat hole are made of base shaft, and the inner ring and shaft are made of base hole. There are recommended values in national standards for matching categories, which can be selected according to specific conditions. Bearings are generally lubricated with grease and oil.

Stuffing box

When the pump shaft passes through the pump casing, there is a gap between the shaft and the casing.

In a single-suction centrifugal pump, if the shaft sealing device is not used in this part, the high-pressure water in the pump casing will leak out in large quantities.

The stuffing box is a commonly used shaft sealing device. The stuffing box is composed of shaft seal sleeve, packing, water seal pipe, water seal ring and packing gland.

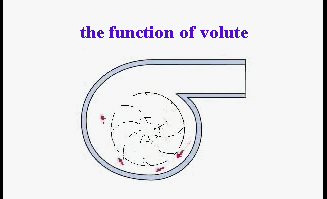

Volute

The volute refers to a spiral flow channel with a gradually increasing cross-sectional area between the impeller outlet to the next stage impeller inlet or to the pump outlet pipe. The flow channel gradually expands, and the outlet is in the shape of a diffuser tube. After the liquid flows out of the impeller, its flow rate can be gently reduced, so that a large part of the kinetic energy is converted into static pressure energy.

The advantages of the volute are that it is easy to manufacture, has a wide high-efficiency area, and the efficiency of the pump changes less after turning the impeller.

The disadvantage is that the shape of the volute is asymmetric, and the pressure acting on the radial direction of the rotor is not uniform when using a single volute, which is easy to bend the shaft. Therefore, in the multi-stage pump, only the volute is used in the first section and the tail section, and the guide wheel is used in the middle section. device.

The material of the volute is generally cast iron. The volute of the anti-corrosion pump is made of stainless steel or other anti-corrosion materials, such as plastic glass fiber reinforced plastic. Due to the high pressure, the multi-stage pump requires high material strength, and its volute is generally made of cast steel.

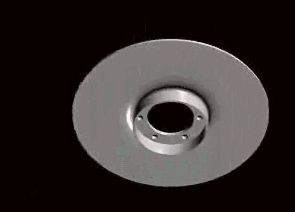

Guide wheel

The guide wheel is a fixed disc with forward guide vanes wrapped around the outer edge of the impeller on the front. These guide vanes form a diffusion-shaped flow channel, and on the back there are reverse guide vanes that guide the liquid to the population of the next stage of the impeller. . After the liquid is thrown out from the impeller, it enters the guide wheel smoothly, and continues to flow outward along the forward guide vane. The speed gradually decreases, and most of the kinetic energy is converted into static pressure energy.

The radial unilateral clearance between the impeller and the guide vane is about 1 mm. If the gap is too large, the efficiency will be reduced; if the gap is too small, it will cause vibration and noise. Compared with the volute, the pump casing of the segmented multi-stage centrifugal pump using the guide wheel is easy to manufacture, and the energy transfer efficiency is also higher. But the installation and maintenance is more difficult than the volute.

Seal ring

In order to reduce internal leakage and protect the pump casing, a removable sealing ring is installed on the casing corresponding to the inlet of the impeller.

The radial clearance between the inner hole of the seal ring and the outer circle of the impeller is generally between 0.1-0.2mm.

After the sealing ring is worn, the radial clearance will increase, the discharge volume of the pump will be reduced, and the efficiency will be reduced. When the sealing clearance exceeds the specified value, it should be replaced in time.