What are the Different Types of Centrifugal Pumps?

Centrifugal pumps are currently utilized across a vast array of domestic and industrial processes. From supplying the water used in residential buildings to industrial applications like food, beverage, and chemical manufacturing, different types of centrifugal pumps are required to effectively meet pumping requirements. For those that are not that familiar with this device, a typical centrifugal pump comprises one or more impellers attached to a rotary pump shaft.

The centrifugal pumps can be classified based on many factors such as construction, design, application, service, and industrial standards. Therefore, one centrifugal pump can be placed into different groups at the same time. In this article, we will introduce three classifications of centrifugal pumps.

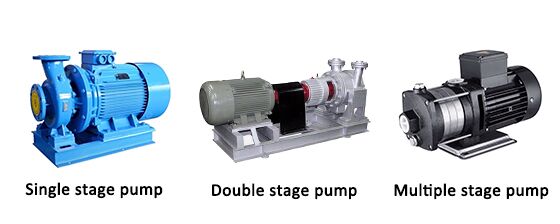

Number of Impeller:

Depending on the number of impellers in the pump, pumps can be classified as the following:

- Single-stage pumps. The single-stage centrifugal pump has a single impeller, featuring a simple design and easy maintenance.These pumps are excellent for applications with high flow rates and also, low-pressure purposes. They are commonly used in pumping services of high flow and total dynamic head (TDH) from low to moderate ranges.

- Double-stage pumps. This type of pump houses two impellers operating side by side and is generally used in middle-head applications.

- Multiple-stage pumps. The multi-stage pumps are designed with three or more impellers connected in series. These pumps are engineered to achieve maximal efficiency and are best for high head applications.

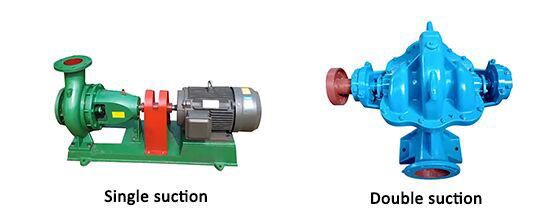

Design of Impeller:

- Single suction. This kind of pump has a single suction impeller that allows fluid to enter the blades only through one side; It has a simple design but impeller has a higher axial thrust imbalance due to flow coming in on one side of impeller only.

- Double suction. This particular type of pump comes with a double suction impeller that allows fluid to enter from both sides of the blades and has lower NPSHR (Net Positive Suction Head Required) than a single suction impeller. Split-case pumps are the most common type of pump with a double suction impeller. If a pump has more than one impeller, the design of the first stage impeller will determine if the pump is of a single or double suction type.

Shaft Orientation:

Shaft orientation is another characteristic which distinguishes the type of centrifugal pumps:

- Horizontal. These are pumps with the shaft in the horizontal plane; popular due to ease of servicing and maintenance. It is sometimes overhung or placed between bearing design.

- Vertical. Vertical centrifugal pumps have their shaft in the vertical plane. They utilize a unique shaft and bearing support configuration that allows the volute to hang in the sump while the bearings are outside the sump. it is generally an overhung and of radial-split case type design.

Standard and custom-built centrifugal pump can be provided in ATO industrial automation. You can choose different models centrifugal pump in our website. If you want to know more about the classification of centrifugal pumps, please click this video.