Why Choose a Centrifugal Water Pump?

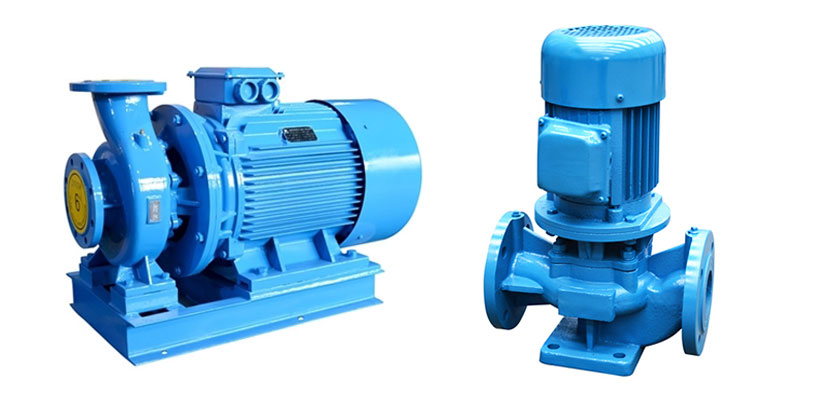

Centrifugal water pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping.

Centrifugal water pumps are ideal for conveying low viscosity fluids in food, dairy, beverage and other high purity applications. Centrifugal pumps are the most common type of process pump and are designed to provide various advantages for food grade pump applications.

5 reasons to choose a centrifugal water pump

- Flexibility

Sanitary centrifugal water pumps can provide high flow rates and accommodate clean-in-place (CIP) procedures. They have a small footprint and flexibility in various configurations to provide a wide range of pressure outputs and flow rates. In some food grade pump applications, sanitary centrifugal pumps can accommodate liquids containing some small solids or suspended particles, adding to their already robust product. - Performance

Our leading Alfa Laval centrifugal pump LKH range features a uniquely designed semi-open impeller and special vane design to ensure exceptionally low NPSHr (requires net positive suction head). This helps prevent cavitation, minimizes the risk of mechanical damage, and ensures smooth, pulse-free flow and reliable performance.

- Outstanding Efficiency

Sanitary centrifugal pumps employ an internal impeller that uses centrifugal force to "throw" material against the outer walls of the pump to force fluid out of the pump. Since lower viscosity fluids are more easily accelerated by centrifugal force, this design provides higher fluid transfer efficiency than other food grade pump designs. - Cleanability

Dairy, food, beverage and other high purity food grade pump applications require hygienic processing conditions to prevent contamination. Therefore, daily cleaning is a top priority. While relatively simple in design, sanitary centrifugal pumps and cleaning methods do vary by manufacturer.

ATO pumps pay more attention to cleanability and hygienic design. Controlled compression gaskets, gapless internals, external mechanical seals and optimized impellers with balanced holes all ensure that the pump is thoroughly cleaned during an efficient CIP cycle. Perfectly aligned components and fittings with O-rings tightened to a predefined compression minimize elastomer product contact surfaces, which also guarantee hygiene. - Low cost

Generally speaking, the upfront cost of sanitary centrifugal water pumps is relatively low. Their reliability, flexibility and high efficiency all result in a lower total cost of ownership than other food grade pumps. Another consideration for total cost of ownership is the maintainability of sanitary centrifugal pumps. Spare parts, maintenance or repair downtime and man-hours can significantly impact overall operating costs. A well thought out pump design ensures easy maintenance.

Overall, the flexibility, performance, efficiency, cleanability and relatively low cost of sanitary centrifugal pumps make them the first choice for many food, beverage and dairy processors. For centrifugal pumps meeting pharmaceutical grade specifications.