Peristaltic Pump: Structure, Working Principle and Selection

Peristaltic pump is also called peristaltic metering pump, constant flow pump, peristaltic hose pump. A peristaltic pump is a liquid transmission device that can control the flow rate. By repeatedly compressing the elastic tubing, the liquid in hose moves in a certain direction, and its flow rate is determined by the diameter of tubing and the compression speed. The liquid is delivered by alternately squeezing and releasing the elastic delivery hose of the pump. Because the high flow peristaltic pump outputs a fixed amount of fluid every revolution, the peristaltic pump is also a kind of precision liquid dispenser, which can achieve precise metering and dosing transmission by adjusting the speed and timing. In this article, we will introduce structure, working principle and selection of peristaltic pump.

Peristaltic hose pumps are typically found in medical testing equipment, environment protection equipment, analysis instruments, inkjet printers, washing machinery, food and beverages manufacturing, scientific experiments, pharmaceutical production, intelligent domestic appliances as well as industrial machinery, etc.

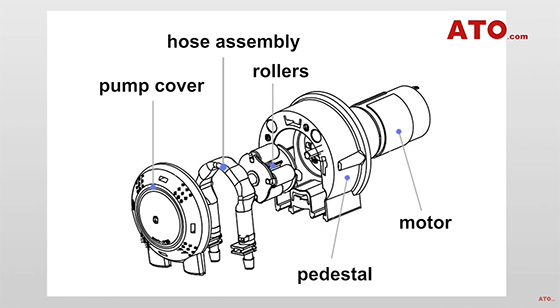

Peristaltic Pump Structure:

A peristaltic hose pump is composed of a pump cover, hose assembly, rollers, a pedestal and a motor, sometimes plus a gearbox if necessary.

- Pump cover. We have different colors of pump cover for customers to choose and transparent design provides the best view of the inner structure.

- Hose assembly. The pump tubing is available in three kinds of size.

- Rollers. Different roller configurations come with distinctive features with double rollers having a larger flow rate and four rollers producing less pulsation.

- Pedestal. The pedestal is made of imported materials, delivering remarkable performance and reliability.

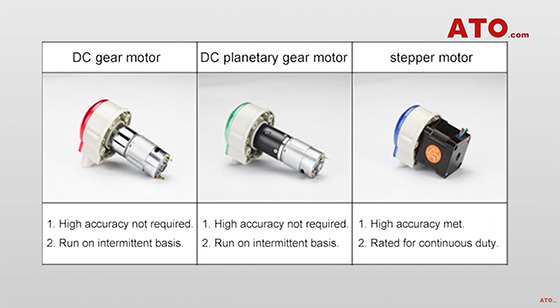

- Motor. There are mini peristaltic pumps that are suitable for DC gear motors, DC planetary gear motors and stepper motors and these motors can also be found at ATO online shop.

How Does a Peristaltic Pump Work?

We are gonna use a DC gear motor-driven pump to show you how it works. The small peristaltic pump shown is model ATO-PP-104KAZL and it's rated at 24V DC with pumping volume being 220mL/min.

A mini peristaltic pump works like squeezing a fluid-filled hose between your fingers. The fluid moves forward as you slide your finger forward. Peristaltic pumps work the same way, but with rollers instead of fingers. The fluid is pumped by alternately squeezing and releasing the pump's flexible delivery hose. Like squeezing a hose between two fingers, as the fingers move, negative pressure forms inside the tube and the liquid flows with it.

High precision peristaltic pump is a "pillow" shaped fluid formed in a pump tube between two rotating rollers. The volume of the "pillow" depends on the inner diameter of the pump tube and the geometry of the rotor. The flow rate depends on the product of three parameters: the speed of the pump head and the size of the "pillows" and the number of "pillows" produced by the rotor per revolution.

How to Select the Right Peristaltic Pump?

There are three kinds of motors that can be used to actuate the peristaltic pump. They are DC gear motors, DC planetary gear motors and stepper motors. We can choose peristaltic pumps according to different needs and situations.

- To choose a proper peristaltic pump for a particular application, there are a number of factors that need to be considered. They include flow, pressure, viscosity of pumped media, temperature limitations, suction lift and so on.

- The type of power supply also needs to be factored into selection consideration. Be sure which kind of power supply is required.

- Pump configuration selection includes working modes and control methods. Consider whether you need direct switching control, analog control and pulsation containment in stepping systems.

- Selecting the right hose (or tube) for the pump is also of great importance for the success of the job. It is advised to choose the correct hose with a right size, desired lifespan and chemical compatibility.

If you want to know more information about peristaltic pump, please click this video.