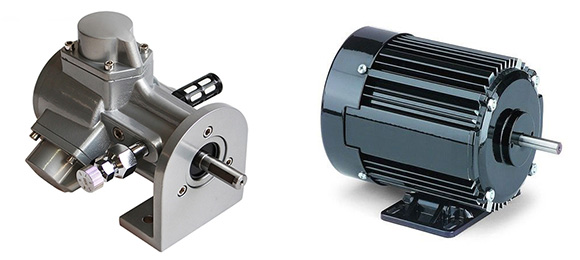

Air Motor vs. Electrical Motor

When it comes to motors, the first thing that comes to mind is electric motors. But if you're looking for a motor with torque and energy efficiency, check out an air motor. Choosing the right motor type depends on your application and surrounding environment. Electric motors are useful for small items; air motors are great for factories, manufacturing facilities, etc. This article introduces something differernt between air motor and elecrical motor.

For example, when you're mixing a 10000-gallon bucket of liquid, which motor you use can make a big difference. Speed, torque, energy efficiency and the environment play a important role in deciding which motor you should use. Using the wrong motor will slow down the manufacturing process and cause inefficiencies. The right motor will speed up your process and improve overall operational performance.

Applied Torque and Power Output:

The biggest advantage of an air motor over an electric motor is torque. The air motor allows you to adjust the torque output according to different needs. The pneumatic motor has a dynamically generated torque load. Electric motors derive their power from alternating current (AC) or direct current (DC) electric motors. The electric motor is powered by a 12 volt outlet or battery. Although there are multiple speed settings, the torque of the motor remains the same.

Unlike electric motors, air motors increase or decrease motor torque to meet precise mixing requirements. The most common types of air motors used in industrial processes are vane air motor and piston air motor. They generate torque by changing the air pressure to turn the motor. The more air that passes through, the faster the motor spins, resulting in less torque. As the pressure increases, the motor spins slower and the torque increases.

An air pressure of 20 pounds per square inch (psi) produces a 2500 revolutions per minute (rpm) motor. This produces an output of about 1 horsepower. Most air motors have a maximum horsepower output of around 4. To make the motor spin at the same speed, the motor increases the psi to 100. Electric motors do not have this versatility. If the torque is overloaded, the motor can jam or even be damaged. Air motor compensation increases torque demand with more air pressure until demand is met.

Energy Efficiency:

Electric motors are more efficient than air motors. The electric motor provides air pressure directly to the sealed motor box. The air motor relies on external air compression to deliver to the motor box.

Air motors require tubes, elbows, and fittings to filter out small amounts of air. Even with these small efficiency drops, air motors provide many times the output power as electric motors. However, the extra energy comes at the cost of reduced energy efficiency.

Precision Speed Control:

The speed at which the motor can run is variable with the air motor. Responds accordingly to the speed and torque of the motor by increasing the air pressure. However, electric motors only provide variable speed control while charging. Pneumatic motors work to produce precise results with every use. You can count on the same production quality over the life of the motor. Electric motors are less reliable, and over time, their efficiency drops.

Environmental Factors:

In an air motor or motor, the biggest consideration is the environment in which it is intended to be used, as some environments are dangerous for the motor. Air motor is suitable for a wide range and is the first choice for working in environments where corrosion can occur.

The design of the motor ensures the explosion-proof performance of the unit. Such enclosures require that the motor enclosures be placed very closely together with very little space between the parts. The casing of these motors eventually collects moisture and corrodes the moving parts of the motor. Air motors rely on compressed air, not moving parts, so air motors are safe to use in wet environments.

All in all, there are many differences between air motor and electric motor. But considering many factors, air motor is more widely uesd than electric motor. If you want to know more information about air motor, please contact us.