How does a Water Ring Vacuum Pump Work?

The working principle of water ring vacuum pump is to use water as the sealing medium to generate vacuum by rotating the water ring. Specifically, the main parts of water ring vacuum pump include pump body, water ring, impeller, inlet and outlet. When the water ring in the pump body rotates, a closed space is formed between the water ring and the pump body, and the gas at the inlet port is sucked into the inside of the water ring, and with the rotation of the water ring, the gas is compressed and discharged from the pump body. Due to the fast rotation speed of the water ring, the residence time of the gas inside the water ring is very short, so the water ring vacuum pump can produce a high vacuum degree.

Working principle of water ring pump

Water ring vacuum pumps are used to pump air or other non-corrosive, water-insoluble, solid particle-free gases to form a certain vacuum in the pumped closed container.

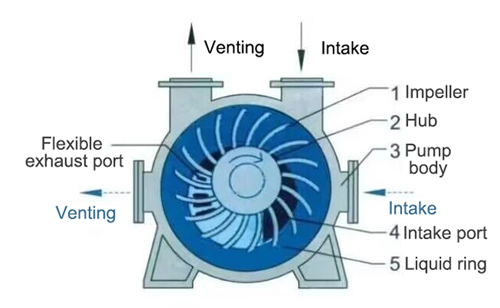

The working principle of water ring vacuum pump is shown in the figure as follows:

- Continuously injected replenishment fluid to replenish the liquid carried away by the expelled gas liquid carried away by the expelled gas.

- The impeller rotates to make the working fluid in the oval pump body to form a liquid ring. The working fluid forms a liquid ring in the elliptical pump body, at this time the working fluid simultaneously plays the role of sealing medium, compression medium and cooling medium. medium, compressed medium and cooling medium at the same time.

- In the exhaust phase, the liquid ring is gradually approaching the wheel, and the pumped medium is discharged from the exhaust port along the shaft.

- During the suction phase, the liquid ring gradually moves away from the hub, the pumping medium is sucked in axially from the suction port.

- Because the impeller is eccentric with respect to the rotating liquid ring, the liquid reciprocates in the space between the blades and produces suction and compression of the pumped medium.

For information on other pumps, go to ATO.com.

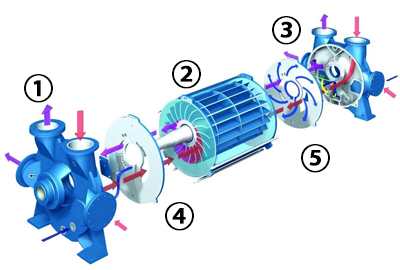

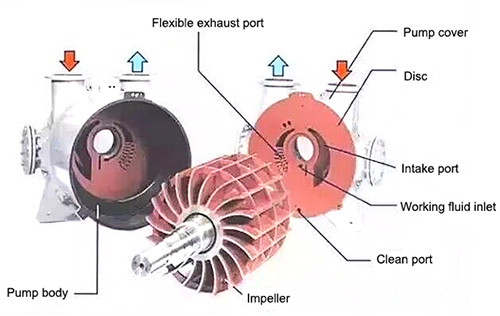

Structure of water ring pump

The water ring vacuum pump mainly consists of impeller, casing and suction and discharge discs, and the impeller consists of blades and hub and other parts.

It is in the casing to form a cylindrical space, the impeller is mounted eccentrically in which, at the same time in the appropriate position of the casing to open the suction port and exhaust port, suction port and exhaust port opened in the impeller side of the casing of the gas distributor.

The casing not only provides working space for the impeller, but also plays a more important role in directly influencing the movement of the working medium (water) inside the pump, thus affecting the energy conversion process inside the pump.

Water ring vacuum pumps need to be filled with a certain amount of water into the pump before working, which plays the role of medium for transferring energy.

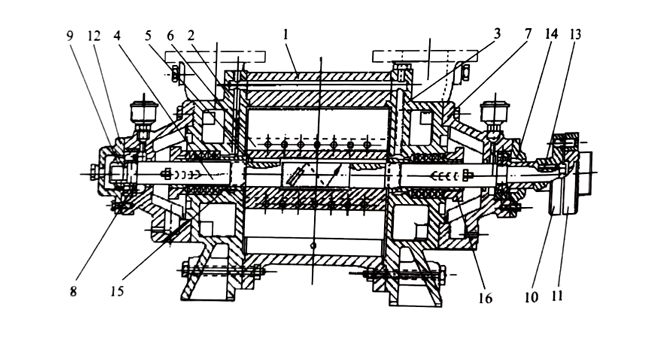

| 1 | 2 | 3 | 4 |

| Pump Body | Back Cover | Front Cover | Pump Shaft |

| 5 | 6 | 7 | 8 |

| Flat Key | Impeller | Bearing Tile Racks | Ball Bearing |

| 9 | 10 | 11 | 12 |

| Round Nut | Pump Coupling | Motor Coupling | Bearing Cover |

| 13 | 14 | 15 | 16 |

| Linchpin | Positioning Ring | Axle Sleeve | Packing Gland |