Water Ring Vacuum Pump vs. Rotary Vane Vacuum Pump

A pump is a machine that transports or pressurises a fluid, mainly used to transport water, oil, slurries, acid and alkali liquids, emulsions, suspensions, gas mixtures and liquid metals, etc. It is a common conveying equipment in the mining, chemical and metallurgical industries.

This blog focuses on comparing the difference between water ring vacuum pumps and rotary vane vacuum pumps.

Water Ring Vacuum Pump

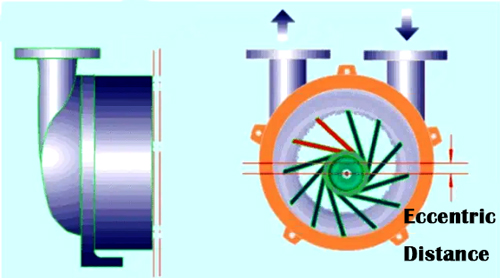

Working Principle: The impeller of the water ring vacuum pump vane is mounted eccentrically in the cylindrical pump casing. A certain amount of water is injected into the pump. When the impeller rotates, the water is thrown to the pump casing to form a water ring, and the inner surface of the ring is tangent to the hub of the impeller.

As the pump casing is not concentric with the impeller, the air intake space between the right half of the hub and the water ring is gradually enlarged, thus forming a vacuum, so that the gas enters the air intake space in the pump through the air intake pipe.

Subsequently, the gas enters into the left half, because the volume between the hub and the ring is gradually compressed to increase the pressure, so the gas is discharged to the outside of the pump through the exhaust space and the exhaust pipe.

Advantages of water ring vacuum pump:

- Simple structure, low manufacturing precision requirement, easy to process.

- Compact structure, high pump rotation, generally can be directly connected with electric motor without deceleration device. Therefore, with small structural dimensions, large exhaust volume can be obtained, and the floor space is also small.

- The compressed gas is basically isothermal, i.e. the temperature change of the compressed gas process is very small.

- Since there is no metal friction surface in the pump cavity, there is no need to lubricate the pump and the wear is small. The sealing between rotating and fixed parts can be done directly by water seal.

- The suction is even, the work is smooth and reliable, the operation is simple and the maintenance is convenient.

Disadvantages of water ring vacuum pump:

- Low efficiency, generally around 30%, better up to 50%.

- Low vacuum, not only because of the structural limitations, but more importantly by the working fluid saturated vapour pressure limitations. Water as the working fluid, the limit pressure can only reach 2000 ~ 4000 Pa. With oil as the working fluid, up to 130 Pa.

- In short, because the gas compression in the water ring pump is isothermal, so it can be pumped out of flammable and explosive gases. Because there is no exhaust valve and friction surface, it can pump out the gas with dust, condensable gas and gas-water mixture. With these outstanding features, despite its low efficiency, it is still widely used.

Rotary vane vacuum pump

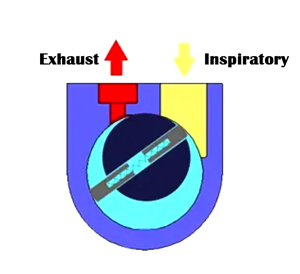

Working Principle: The rotary vane of the rotary vane pump separates the crescent-shaped space surrounded by the rotor, pump chamber and two end caps into A, B and C. When the rotor rotates in the direction of the arrow, the volume of the space A communicated with the suction port is gradually increasing, which is in the suction process.

The volume of the space C connected with the exhaust port is gradually reduced, in the process of exhaust. The volume of space B in the centre is also gradually decreasing and is in the compression process.

As the volume of space A is gradually increasing (i.e. expanding), the gas pressure decreases, and the external gas pressure at the inlet of the pump is greater than that in space A, so the gas is drawn in.

When space A is isolated from the suction port, i.e. turned to the position of space B, the gas begins to be compressed, the volume is gradually reduced, and finally connected to the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas is discharged to the atmosphere through the oil layer in the tank.

The purpose of continuous pumping is achieved by the continuous operation of the pump. If the discharged gas passes through the airway and is transferred to another stage (low vacuum stage), pumped away by the low vacuum stage, and then compressed by the low vacuum stage and discharged to the atmosphere, i.e., it is composed of a two-stage pump.

At this time, the total compression ratio is burdened by two stages, thus improving the ultimate vacuum.

Performance characteristics of rotary vane vacuum pump:

Rotary vane vacuum pump is a kind of oil-sealed mechanical vacuum pump, which belongs to low vacuum pump and can be used alone, or as a pre-stage pump of other high vacuum pump or ultra-high vacuum pump. It is widely used in metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum and medicine and other production and scientific research departments.

Small volume, light weight, low noise;

Equipped with gas ballast valve, which can pump out a small amount of water vapour;

Equipped with automatic anti-return oil check valve, easy to start;

The air inlet should not be open to the atmosphere continuously for more than one minute;

It is not suitable for pumping out gases that are corrosive to metals, chemically reactive to pump oil, containing particles of dust, and gases that are too high in oxygen, explosive and toxic.