What is the Water Ring Vacuum Pump?

The water ring vacuum pump is equipped with an eccentric rotor with fixed vanes, which is a rotary variable volume vacuum pump that throws water (liquid) to the stator wall, the water (liquid) forms a liquid ring concentric with the stator, and the liquid ring and the rotor vanes together constitute a variable volume.

Water ring vacuum pump (water ring pump for short) is a kind of rough vacuum pump, the ultimate vacuum it can get is 2000~4000 Pa, and the vacuum degree of unit with vacuum pump can reach 1~600 Pa. Water ring pump can also be used as a compressor, which is called water ring compressor, and it is a kind of low pressure compressor, and its pressure ranges from 1~2×10^5 Pa gauge pressure.

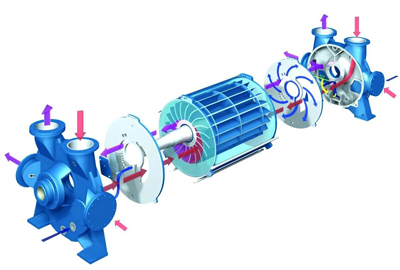

Water Ring Vacuum Pump Working Principle

Water ring pumps were initially used as self-priming pumps, and then gradually used in many industrial sectors such as petroleum, chemical, machinery, mining, light industry, medicine and food. In many processes of industrial production, such as vacuum filtration, vacuum water diversion, vacuum feeding, vacuum evaporation, vacuum concentration, vacuum moisture back and vacuum degassing, etc., water ring pumps are widely used. Due to the leaping development of vacuum application technology, water ring pumps have been valued in pumping vacuum to obtain. As the gas compression in the water ring pump is isothermal, it can pump out flammable and explosive gases, in addition, it can also pump out dusty and watery gases, so the application of water ring pump is increasing. As shown in Figure 1: (see additional pictures) the pump body is equipped with an appropriate amount of water as the working fluid. When the impeller rotates clockwise in the direction indicated in Figure 1, the water is thrown around by the impeller, and due to the centrifugal force, the water forms a closed ring of approximately equal thickness that determines the shape of the pump chamber. The upper part of the inner surface of the water ring is exactly tangent to the impeller hub, the lower part of the inner surface of the water ring is just in contact with the top of the blade (in fact, there is a certain insertion depth of the blade in the water ring). At this time between the impeller hub and the water ring to form a crescent-shaped space, and this space is divided into a number of small cavities with equal number of blades by the impeller. If the upper part of the impeller 0° as a starting point, then the impeller in the rotation of the first 180° when the volume of the small cavity from small to large, and with the end of the surface of the suction port, the gas is sucked in at this time, when the suction end of the small cavity and suction port isolation; when the impeller continues to rotate, the small cavity from the large to small, so that the gas is compressed; when the small cavity and the exhaust port when the gas is discharged out of the pump.

To sum up, the water ring pump relies on the change of pump cavity volume to achieve suction, compression and exhaust, so it belongs to variable capacity vacuum pump.

Figure 1

Water Ring Vacuum Pump Features

- Easy maintenance: The temperature of compressed gas is low, the exhaust temperature is only 10~15℃ higher than the inlet temperature, because of this feature, it is very easy to be suitable for pumping and conveying flammable and explosive gases.

- Scope of application: Mainly used in coal mine (gas pumping), chemical, pharmaceutical, mining, papermaking, food, beer, building materials, plastics, metallurgy, electrical appliances and other industries.

- Flexible configuration: It can be assembled with separator, heat exchanger, pipeline, valve, instrument, electric control device together on a chassis as a complete set of equipment.

Pros and Cons

Advantages

- Simple structure, low manufacturing precision, easy to process.

- Compact structure, pump speed is high, generally can be directly connected with the motor, without deceleration device. Therefore, a large exhaust volume can be obtained with small structural dimensions and a small floor space.

- The compressed gas is basically isothermal, i.e. the temperature change of the compressed gas process is very small.

- Since there is no metal friction surface in the pump cavity, there is no need to lubricate the pump and the wear is small. The sealing between rotating and fixed parts can be done directly by water seal.

- The suction is even, the work is smooth and reliable, the operation is simple and the maintenance is convenient.

Disadvantages

- Low efficiency, generally around 30%, better up to 50%.

- Low vacuum, not only because of the structural limitations, but more importantly by the working fluid saturation vapour pressure limit. Water as working fluid, the limit pressure can only reach 2000 ~ 4000 Pa. With oil as working fluid, up to 130 Pa.

- In short, since the gas compression in the water ring pump is isothermal, flammable and explosive gases can be pumped out. Because there is no exhaust valve and friction surface, it can pump out the gas with dust, condensable gas and gas-water mixture. With these outstanding features, despite its low efficiency, it is still widely used.