Types of Air Motor: Geared, Piston and Vane Air Motor

Air motor is a continuously rotating pneumatic actuator, is a compressed air pressure energy into rotary mechanical energy conversion device. It outputs torque and drives the actuator to rotate. There are three main types of pneumatic motors: vane air motor, piston air motor, geared air motor. This article mainly introduces the types of air motor.

Vane Air Motor:

The vane air motor is a device that can convert the pressure of compressed air into rotational mechanical energy. The most widely used in pneumatic transmission are vane and piston types. It is mainly composed of motor housing, connecting rod, crankshaft, piston, cylinder, valve and so on. The compressed air enters the valve core to make it rotate, and at the same time, the compressed air is fed into the surrounding cylinders in turn by the rotation of the valve core. Due to the expansion of the compressed air in the cylinder, the piston rod and the crankshaft are pushed to rotate. When pushed to the "bottom dead center", the valve spool of air motor also moves to the first exhaust position.

Air vane motors consist of a cylinder (called a stator) that contains an eccentric rotor closed at both ends. The space between the stator and rotor is kidney-shaped. The rotor has grooves in which the blades can move freely. Compressed air enters the motor at one end and exits through openings in the cylinder. To ensure the motor starts correctly, the air first enters under the vanes, pushing the vanes against the inner wall of the cylinder. Once the motor starts, centrifugal force comes into play.

The advantage of vane air motors is their simplicity of design. Service is easy as the motor is easy to remove and worn parts (filters, vanes) are cheap to replace. The most common type of pneumatic motor is the compact, economical and simple design, which is perfectly suitable for use in numerous equipments in various industrial sectors such as agriculture, food, petrochemical, and even the nuclear industry.

Air vane motors work with clean, filtered air and should be properly lubricated. Depending on the equipment or intended end use, a specially designed motor can be selected and can be used without lubrication. The vane motor rotates at a higher speed and provides more power relative to the weight of the piston motor. However, the effective starting torque they provide is lower. Blade motors are lighter and less expensive than piston motors, and operate at the same power.

Piston Air Motor:

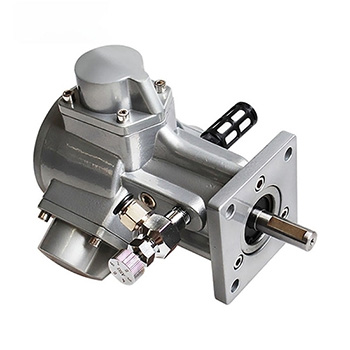

A piston air motor is an pneumatic motor that converts the linear motion of several pistons into rotary motion through a crank or a swash plate. According to their different structures, they can be divided into radial piston type and axial piston type. Piston air motors are suitable for applications with low speed and high torque. The air consumption is not small, which has many components, and the price is expensive. Piston-type air motors are mainly used in mining machinery, and can also be used as drive motors for conveyor belts, etc.

Piston air motors have 4 to 6 cylinders. Power is created by the pressure within each cylinder. They rev lower than vane engines. These motors have a high starting torque and control their speed well. They are suitable for heavy duty work at low speed. The piston can be axial or radial. The basic idea of a piston air motor is to provide a motor that provides a high torque while spinning at a low speed.

Geared Air Motor:

The gear air motor comprises a cylinder, which is enclosed with a holding groove, an intake flow channel and an exhaust flow channel, the intake flow channel and the exhaust flow channel respectively connected with the holding groove, the cylinder has an inner wall, located in the holding groove surface.

And a rotor, includes a spindle, multiple main blade and short blade, wherein the spindle off center and can rotate to set in for slot, in the outer ring is arranged on the surface of earth is equipped with multiple concave axial-radial direction into the heart of main chute and vice chute, the blades can be radial slip slide in main chute, each pair of blade can be radial slip slide in vice chute, the lord The blade rotates with the mandrel and against the inner wall when the mandrel rotates, and a part of the auxiliary blade on the rotation Angle is in contact with the inner wall of the cylinder when the mandrel rotates. The invention can greatly increase the cylinder output torque on the premise that the rotor speed is maintained in the allowable working speed range.