What is a Needle Valve?

Needle valve is a pipeline accessory. It is a device used to change the cross-section of the passage and the direction of medium flow, and to control the flow of the conveying medium. It is named after the shape of the valve body, similar to a slender needle. This type of valve is typically used in applications that require precise flow regulation, such as laboratory equipment, analytical instruments, chemical production, and other industrial processes. In this article, ATO industrial automation will introduce the basic information about the needle valve (including working principle, classification, advantages and its applicaiton) for you.

Working Principle of Needle Valves

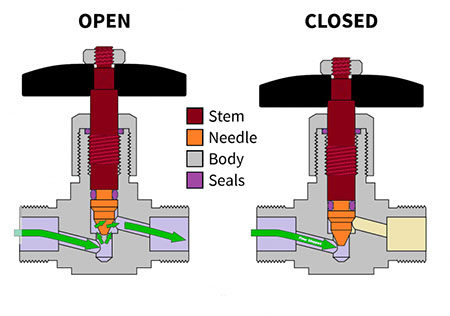

The working principle of a needle valve is based on the sealing effect between the valve core and the valve seat. The opening degree of the valve port is adjusted by controlling the lifting of the valve core, thereby controlling the flow rate of the fluid. When the valve core is tightly attached to the valve seat, the valve port closes and fluid cannot pass through. However, when the valve core is separated from the valve seat, the valve port opens and fluid can pass through smoothly.

Specifically, when the handle or electric device on the valve stem rotates or lifts, the valve core also rises and falls accordingly. When the valve core rises, it separates from the valve seat, forming a valve port of a certain size, and fluid flows through the valve port; When the valve core descends, the valve core adheres to the valve seat, the valve port closes, and the fluid stops flowing.

Classification of Needle Valves

According to the different functions of needle valves, it can be divided into the following categories:

- According to its purpose, it can be divided into: block valve, check valve, safety valve, regulating valve, and diverter valve.

- According to the different nominal pressures in use, it can be divided into: vacuum valve, low-pressure valve, medium pressure valve, high-pressure valve, ultra-high pressure valve.

- According to the normal operating temperature classification, it can be divided into: ultra-low temperature valve, low-temperature valve, room temperature valve, medium temperature valve, and high-temperature valve.

- According to the braking method: automatic valve (including safety valve, pressure reducing valve, drain valve, check valve, and automatic regulating valve), and driving valve (which can be further classified into electric valve, pneumatic valve, hydraulic valve, gas-driven valve), and manual valve.

- According to the diameter of fluid passing through the valve: small-bore needle valve, medium-bore needle valve, large-bore needle valve, and extra-large-bore needle valve.

- According to the structural shape of the needle valve: gate-shaped, plug-shaped, plug valve, globe valve, butterfly-shaped, and slide valve.

- According to the connection mode with other pipes and fittings: threaded connection needle valve, flange connection needle valve, welded connection needle valve, clamp connection needle valve, sleeve connection needle valve, and clamp connection needle valve.

- According to the material used in manufacturing the needle valve: metal material needle valve(such as brass needle valve), non-metal material needle valve, and metal valve body lining needle valve.

Advantages of Needle Valves:

- High precision and adjustment performance

Due to the small contact area between the valve core and the valve seat, it provides more accurate regulation of fluid flow. - Continuous up and down movement of the valve core

It allows minor adjustments according to actual needs, meeting flow requirements under different operating conditions. - Excellent sealing performance

It is effectively prevents fluid leakage, enhancing system safety and stability.

Application of Needle Valves:

Needle valves have several uses, including:

- Opening or closing the medium in pipeline, such as gate valves, globe valves, ball valves, plug valves, diaphragm valves, butterfly valves, etc.

- Regulating and controlling the flow and pressure of the medium in the pipeline, such as throttle valves, regulating valves, pressure reducing valves, safety valves, etc.

- Changing the direction of medium flow in the pipeline, such as distribution valves, three-way plug valves, three-way or four-way ball valves, etc.

- Preventing backflow of the medium in the pipeline, such as various types of check valves, bottom valves, etc.

- Separating the medium, such as various structures of steam trap valves, air trap valves, etc.

- Indicating and adjusting the liquid level height, such as liquid level indicators, liquid level regulators, etc.

- Other special purposes, such as temperature control valves, emergency cut-off valves for overflow protection, etc.

In summary, the needle valve is a structurally simple and reliable fluid control valve. It regulates the opening of the valve port by the contact and separation of the valve core and valve seat, thereby controlling the flow of fluid. With high precision, excellent adjustment performance, and superior sealing characteristics, needle valves find wide applications in various fields.