Butterfly Valve Buying Guide

Butterfly valves are widely used, so the selection and purchase of butterfly valves is particularly important. Today, we will introduce the selection of butterfly valves so that you can buy a butterfly valve suitable for you.

The plate of the butterfly valve is installed in the diameter direction of the pipeline. The butterfly valve is simple in structure, small in size and light in weight. It only consists of a few parts, and it can be opened and closed quickly by rotating 90°, and the operation is simple. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small

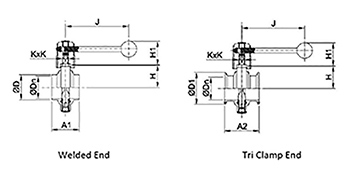

Size and type of butterfly valve

Before buying a butterfly valve, you need to know the size and type of valve.

If a butterfly valve is required for flow control, you need to pay attention to the size and type of valve. The structure principle of the butterfly valve is especially suitable for making large-diameter valves. Commonly used butterfly valves are wafer type butterfly valve and flange type butterfly valve.

Wafer type butterfly valve is to connect the valve between two pipe flanges with stud bolts. Flanged butterfly valve is a process with flanges on the valve, and the flanges at both ends of the valve are connected to the pipeline flange with bolts.

As a component used to realize the on-off and flow control of the pipeline system, the butterfly valve has been widely used in many fields such as petroleum, chemical industry, metallurgy and so on. In butterfly valve technology, the sealing structure is mostly adopted, and the sealing material is rubber, PTFE, etc. Due to the limitation of structural characteristics, it is not suitable for industries such as high temperature resistance, high pressure, corrosion resistance and wear resistance.

A relatively advanced butterfly valve is a triple eccentric metal hard-sealed butterfly valve. The valve body and the valve seat are connected components, and the sealing surface layer of the valve seat is surfacing with temperature-resistant and corrosion-resistant alloy materials. The multi-layer soft stacked sealing ring is fixed on the valve plate. Compared with the traditional butterfly valve, this kind of butterfly valve has the advantages of high temperature resistance, easy operation, no friction when opening and closing. It compensates with the increase of the torque of the transmission mechanism when closing. It improves the sealing performance of the butterfly valve and prolongs the service life.

Applications

In addition to knowing the size and type of the valve, you also need to know the application of the butterfly valve when purchasing.

Butterfly valves are suitable for flow regulation. Since the pressure loss of the butterfly valve in the pipeline is relatively large, the firmness of the butterfly plate to withstand the pressure of the pipeline medium should also be considered when it is closed. Additionally, you must consider the operating temperature limitations of the elastomeric seat material at elevated temperatures. The butterfly valve has a small structural length and overall height, fast opening and closing, and good fluid control characteristics. The structure principle of butterfly valve is most suitable for making large-diameter valve. When the butterfly valve is required to be used for flow control, the most important thing is to correctly select the size and type of the butterfly valve so that it can work properly and effectively.

Generally, in throttling, regulating control and mud medium, short structure length and fast opening and closing speed (1/4 revolution) are required. Low pressure cut-off (small differential pressure), butterfly valve is recommended.

Butterfly valve can be used in two-position adjustment, constricted channel, low noise, cavitation and gasification, a small amount of leakage to the atmosphere, and abrasive medium.

When the butterfly valve is used for throttling adjustment under special working conditions, or requiring strict sealing, or serious wear, low temperature (cryogenic) and other working conditions, it is necessary to use a specially designed metal sealing belt adjustment device for triple eccentric or double eccentric.

Butterfly valve is suitable for fresh water, sewage, sea water, salt water, steam, natural gas, food, medicine, oil and various Acid-base and other pipelines.

Soft-sealed eccentric butterfly valve is suitable for two-way opening and closing and adjustment of ventilation and dust removal pipelines. It is widely used in gas pipelines and waterways of metallurgy, light industry, electric power, and petrochemical systems.

Metal-to-metal wire sealed double eccentric butterfly valve is suitable for urban heating, gas supply, water supply and other gas, oil, acid and alkali pipelines, as a regulating and throttling device.

In addition to being used as a program control valve for a large-scale pressure swing adsorption (PSA) gas separation device, the metal-to-metal surface sealing triple eccentric butterfly valve can also be widely used in petroleum, petrochemical, chemical, metallurgy, electric power and other fields.