How Does a Dielectric Oil Tester Work?

In the realm of electrical equipment maintenance and safety, the dielectric oil tester stands as a stalwart guardian, ensuring the dielectric strength and integrity of insulating oils. But have you ever wondered how this remarkable instrument operates? In this comprehensive exploration, we will delve into the inner workings of a dielectric oil tester, shedding light on the technology behind its critical role in maintaining electrical systems.

Understanding Dielectric Strength

Before we dive into the inner workings of a dielectric oil tester, it's essential to grasp the concept of dielectric strength and its significance. Dielectric strength is a measure of an insulating material's ability to withstand electrical stress without breaking down and allowing current to flow through it. In the context of electrical equipment, insulating oils play a pivotal role in preventing electrical discharges and short circuits, making their dielectric strength a critical factor in operational reliability and safety.

The Core Function: Assessing Dielectric Strength

At its core, a dielectric oil tester is designed to evaluate the dielectric strength of insulating oils. It does so by subjecting a sample of the oil to an increasing electric field until electrical breakdown occurs. The key to this process lies in the meticulous control of voltage and current.

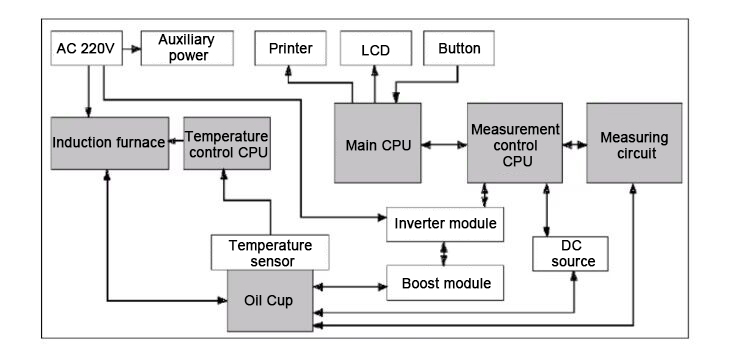

The commonly used equipment for testing the dielectric strength of insulating oil is an insulating oil dielectric strength tester. The instrument mainly consists of a high-voltage generator, measurement circuit and control system. When testing, first place the insulating oil sample in the tester, and then gradually increase the electric field intensity until the insulating oil breaks down. The tester will automatically record the value of the breakdown voltage, and the dielectric strength of the insulating oil can be obtained through calculation.

The results of the dielectric strength test of insulating oil can be used to evaluate the insulating performance of the insulating oil. Typically, the dielectric strength of insulating oil is related to its purity and moisture content. Insulating oils with higher purity and lower water content generally have higher dielectric strength. Therefore, the dielectric strength test can be used to determine whether the insulating oil meets the requirements and whether it needs to be replaced or processed.

The dielectric strength test of insulating oil is of great significance in the maintenance and repair of power equipment. By regularly testing the dielectric strength of insulating oil, the aging, contamination or other defects of the insulating oil can be discovered in time to prevent failures and accidents of power equipment. At the same time, this test can also be used to evaluate the quality of insulating oil to ensure that the performance of the insulating oil is stable and reliable.

The principle of dielectric strength testing of insulating oil is simple and easy to understand, but there are some issues that need to be paid attention to in actual operation. First of all, it is necessary to ensure the purity of the insulating oil sample during testing to avoid interference from external impurities. Secondly, the electric field strength needs to be gradually increased during the test to avoid excessive electric field strength acting on the insulating oil at one time, which may lead to inaccurate test results. In addition, the selection and calibration of testers are also critical. Appropriate instruments need to be selected and calibrated and maintained regularly.

The dielectric strength test of insulating oil is an important method to evaluate the insulation performance of insulating oil. By measuring the breakdown voltage of insulating oil, the insulation performance of insulating oil can be evaluated. This testing method has important application value in the maintenance and repair of power equipment, and can prevent accidents and ensure the safe operation of power equipment.

Here's a step-by-step breakdown of how a dielectric oil tester works:

- Sample Preparation: A small sample of the insulating oil to be tested is carefully extracted and placed in a test cell within the dielectric oil tester.

- Applying an Electric Field: The tester applies a steadily increasing electric field to the oil sample. This electric field is generated by the instrument's internal circuitry.

- Measuring Voltage and Current: As the electric field intensifies, the voltage across the sample and the current passing through it are continuously monitored and recorded.

- Detecting Breakdown: Breakdown occurs when the voltage reaches a critical point at which the insulating oil can no longer resist the electrical stress. At this moment, electrical current starts to flow through the oil.

- Recording the Breakdown Voltage: The voltage at which breakdown occurs is recorded as the breakdown voltage, which is a crucial parameter in assessing the dielectric strength of the oil.

- Analysis and Interpretation: The recorded breakdown voltage is then analyzed, and the results are used to determine the dielectric strength of the insulating oil. This value provides insights into the oil's condition and its ability to effectively insulate electrical components.

A dielectric oil tester is a sophisticated instrument designed to assess the dielectric strength of insulating oils through precise control of voltage and current. Its ability to measure the breakdown voltage is invaluable in ensuring the reliability and safety of electrical equipment across various industries. You can buy a dielectric oil tester at the ATO store. The next time you encounter this essential tool in the world of electrical maintenance, you'll have a deeper understanding of how it operates and its pivotal role in safeguarding electrical systems.