How Does the Aerator Pump Work?

An aerator pump is a device used to increase dissolved oxygen dispatch in a body of water. Its basic principle is through the air through the water body, the use of air bubbles and water contact water to achieve the transfer of oxygen. If you want to better explain the main principle of the work of the aeration pump, first we need to briefly understand what aeration is. Aeration is the transfer of oxygen from the air to the water column through specific equipment to increase the dissolved oxygen content in the water, thus ensuring that the pool microorganisms in the conditions of sufficient dissolved oxygen, the oxidative decomposition of organic matter in sewage. On this basis, ATO will introduce you to further aerator pump work-specific steps.

Aeration Pump Working Steps

Step 1: The Air Pump to Generate Airflow

Motor energized, driven by the shaft and propeller rotation, the water from the inlet into the aerator pump usually used as the air pump will be sucked into the air, and then through the pipeline will be transported by the airflow.

Step 2: Airflow Into the Aerator Pump

The airflow enters the pump through the air inlet, usually through a small hole or a diffuser or other equipment to control the amount of airflow.

Step 3: Bubbles Emerge

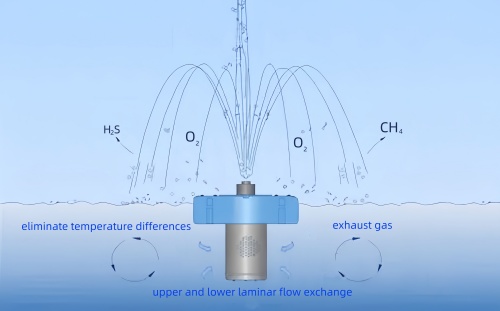

When the airflow into the aeration pump, a large number of bubbles will be formed, after the propeller's pushing effect, these bubbles with the airflow gradually up out of the water surface, from the nozzle of the inflow device.

Step 4: The Bubbles Contact with the Water Body

At this time to open the air pump, adjust the air pump air volume, air from the aeration pipe into the aerator inside, bubbles in the process of bubbling out of the water surface and the water body for full contact, ozone molecules from the bubbles diffuse into the water body.

Step 5: Dissolved Oxygen Increases

Due to the large contact area of bubbles and water, bubbles out of the water surface speed, and gas-water mixture by the propeller mixing, bubbles are fully broken, will produce turbulence in the process of rising, further increasing the contact time and press the contact area of bubbles and water, bubbles in the process of movement with the water in the bubbles in the oxygen component of the water is constantly dissolved, thus making the oxygen faster dissolved into the water, and then from the infusion Sprayed from the device, the effect of aeration is achieved.

It is through the above steps, that the aerator pump can effectively dissolve oxygen into the water body, and improve the dissolved oxygen concentration in the water body. Different types of aerator pumps may have some details on the difference, but overall to improve the concentration of dissolved oxygen in sewage, promote the growth and reproduction of aerobic microorganisms, and accelerate the degradation of pollutants in the process, which is important for aquaculture, sewage treatment, and other environmental and industrial applications.

What is the Difference Between Aeration and Air Supply, Oxygen Supply?

Many people will have this question. In the previous we have explained the aeration, will not repeat, the following to talk about the air supply and oxygen supply.

Gas supply usually refers to the process of providing people with enough gas (usually oxygen or air) to maintain normal breathing in medical, diving, aerospace, or other environments where artificial respiration is required. For example, during diving activities, divers need to carry compressed air cylinders or oxygen cylinders for gas supply.

Oxygen supply is often used in the medical field, especially for people who are unable to obtain enough oxygen through regular breathing, such as patients with severe lung disease or newborns. In these cases, doctors may use oxygen masks, nasal cannulas, or other devices to provide additional oxygen to the patient. According to the theoretical basis of oxygen delivery, oxygen delivery sometimes becomes oxygen transfer or transfer, referring to the transfer or transfer of oxygen from the air bubbles to the water. During the process of aeration, the oxygen in the air is transferred or passed from the gas phase to the liquid phase of the wastewater as a process of diffusion of oxygen between the gas and liquid phases, i.e., the oxygen in the gas phase diffuses through the gas-liquid interface into the main body of the liquid phase. It can be considered that oxygen transfer is actually a diffusion process.

In simple terms, aeration, gas supply, and oxygen supply are all to provide gas, but their application scenarios and purposes are different. Aeration is mainly used in wastewater treatment, gas supply is usually used in environments where artificial respiration is required, while oxygen supply is mainly used in the medical field.