How to Control a VFD with a PLC?

In industrial automation, communication between a Programmable Logic Controller (PLC) and a Variable Frequency Drive (VFD) is essential for controlling motors and adjusting their speed, torque, and other parameters. Here are the general communication types between a PLC and a VFD.

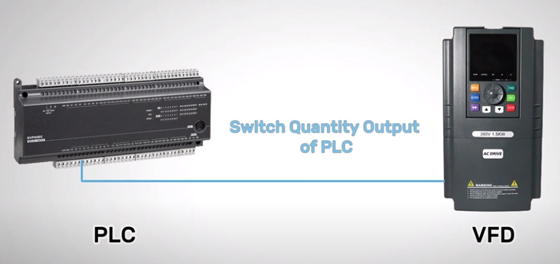

Switch Quantity Output of PLC

This is the most basic connection method. It involves directly connecting the PLC's switch quantity output to the corresponding input of the VFD. The switch quantity output of PLC can control VFD functions like its start/stop, forward/reverse rotation, multi-speed operation, etc., while this method is not suitable for precise speed control.

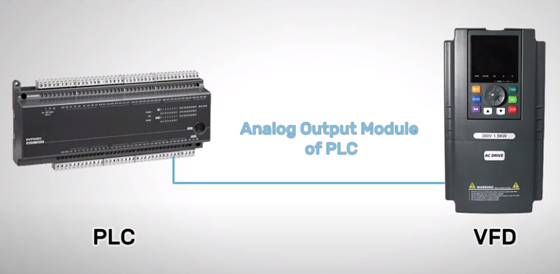

Analog Output Module of PLC

The PLC's analog output module (AO) generates 0-10V or 4-20mA signals, connected to the analog input terminals of the VFD to control the motor speed. This method is ideal for applications that require continuous speed adjustment.

Serial Communication Control

Serial communication control utilizes protocols like RS-485 to establish a connection. The PLC sends control commands and receives status feedback from the VFD through communication modules. Common communication protocols include Modbus, RTU, PROFIBUS, etc. This method enables complex control logic, remote monitoring, and fault diagnostics, and features simple wiring that is easy to expand.

Ethernet Connection

In modern automation systems, PLCs and VFDs can communicate directly through Ethernet interfaces using industrial Ethernet protocols like EtherCAT, Profinet, and Ethernet/IP. This provides high-speed data exchange capabilities and advanced network integration.

The choice of connection method depends on specific application requirements, system complexity, cost considerations, and the need for control precision and flexibility. Understanding these methods is crucial for optimizing automation processes.

You can view the YouTube video below to learn about the major wiring methods between a PLC and a VFD. For more insights and expert advice on industrial automation solutions, visit ato.com to explore our product offerings and elevate your automation projects with our resources and expertise.