How to Select a Right Heat Sink?

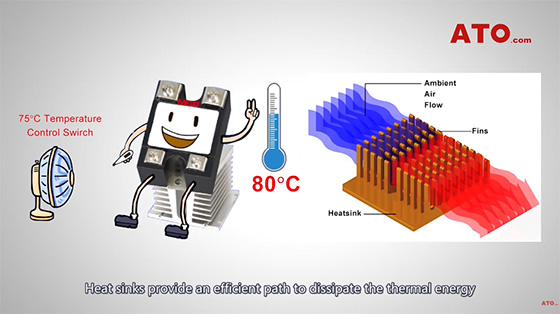

Solid state relays generate heat when they are in operation. A heat sink for a solid state relay is a device that is used to dissipate the heat generated by the solid state relay during its operation. Solid state relays are electronic switching devices that use semiconductors to switch electrical loads on and off. When a solid state relay is in operation, it generates heat due to the resistance of the semiconductors.

The heat sink is designed to absorb and dissipate this heat away from the solid state relay. It is typically made of a thermally conductive material such as aluminum, which helps to transfer the heat away from the solid state relay and into the surrounding air. Choosing the right heat sink helps to increase the efficiency and service life of solid state relays. In this article, ATO automation will help you choose the right heat sink with three questions.

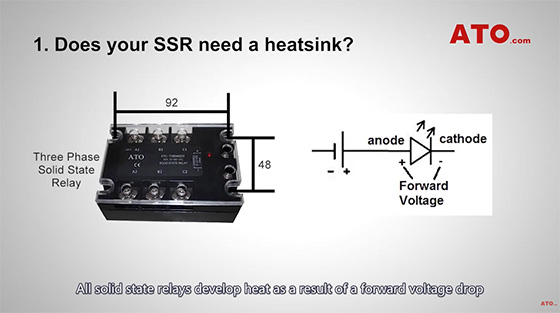

Does your SSR need a heatsink?

All solid state relays develop heat as a result of a forward voltage drop through the junction of the output device. Beyond a point, heat will cause a lowering (or derating) of the load current. With loads of less than 4 amperes, cooling by free flowing convection or forced air currents around the unit is usually sufficient. Loads greater than 4 Amps will require heat sinks. The heat dissipation effect of the heat sink is not only related to its specification (size, shape), but also related to external environmental factors, such as the ambient temperature, ventilation conditions (natural cooling or forced cooling, and ventilation volume), and installation density.

In addition, it is also necessary to consider whether the volume of the solid state relay and the installation space of the heat sink in the equipment matches the specifications of the heat sink. Heat Sinks are made of high thermal conductive material such as aluminum. Not only is aluminum's thermal conductivity high, its cost is relatively low. Heat sink performance is rated by thermal impedance, measured in °C per watt (°C/W). Thermal impedance represents the resistance to the transfer of thermal energy, (thermal impedance is the inverse of thermal conductivity). Therefore lower numerical thermal impedance ratings mean more efficient heat transfer.

Thermal impedance ratings of solid state relay heat sinks are based upon natural convection air flow. To achieve this performance, the heat sink must be oriented such that air flow over its finned surface is maximized. Generally this means the fins should be oriented vertically. Significant improvement in SSR heat sink performance can be achieved by providing forced air flow over the heat sink's surface area. Fans delivering relatively small volumes of air can reduce the heat sink's thermal impedance substantially, thereby improving its efficiency and consequently the SSRs reliability.

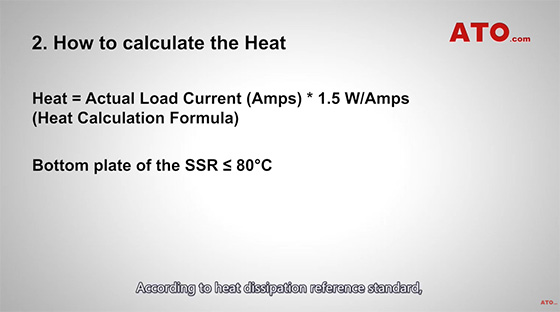

How to calculate the Heat?

The heat generated by the solid state relay in practical applications can be calculated by the following formula: Heat = Actual Load Current (Amps) * 1.5 W/Amps (Heat Calculation Formula). According to heat dissipation reference standard, the temperature of the bottom plate of the solid state relay (the side in contact with the heat sink) should not exceed 80 ℃.

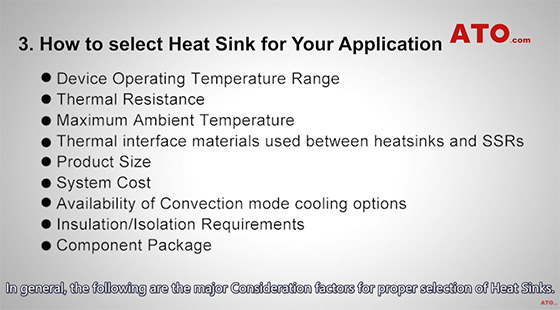

How to select Heat Sink for Your Application?

In general, the following are the major consideration factors for proper selection of heat sinks.

- Device Operating Temperature Range

- Thermal Resistance

- Maximum Ambient Temperature

- Thermal interface materials used between heatsinks and SSRs

- Product Size

- System Cost

- Availability of Convection mode cooling options

- Insulation/Isolation Requirements

- Component Package

If you want to know more information about heat sink, please click this video.