How to Test a Timer Relay?

Testing timer relays is one of the most important steps in ensuring reliable operation of electrical systems. timer relays are widely used in industrial, power, automation, and control systems to trigger, delay, or control various circuits and devices. Testing timer relays help to verify their performance, accuracy, and reliability to ensure their proper operation in critical applications. ATO online shop will detail the steps, methods, and considerations on how to test timer relays to ensure the reliability and safety of electrical systems.

Basic Operating Principles of Timer Relays

Before start testing a timer relay, you first need to understand its basic principle of operation. A timer relay is an electronic device that triggers an output action by delaying it for a certain period of time after an input signal is activated. It usually consists of a timer and a high-quality relay that can be used in different applications to control various circuits and devices.

The Need to Test Timer Relays

The importance of testing safe and raliable relays is to ensure that they work reliably in critical applications. If the timing function of a timer relay is inaccurate, it can lead to circuit failures, equipment damage, or production interruptions. The following are important reasons to test timer relays. Inaccuracies in timer relays can lead to unsafe operation, such as untimely starting or stopping of equipment. Testing helps ensure that relays trigger outputs at safe times.

Timer relays are often used to control the start and stop of equipment. Inaccurate timing can lead to equipment damage or abnormal operation. Timer relays are used to coordinate the operation of different pieces of equipment in manufacturing and production processes. The accuracy of timer relays is critical to the efficiency of the production process. In automation systems, timer relays may be used to synchronize data acquisition and transmission. Accurate timing functions ensure data consistency and accuracy. Timer relays play a critical role in automated control systems. Testing helps ensure system stability and reliability.

Steps for Testing Timer Relays

- Preparation: Before testing, confirm the specifications and requirements of the timer relay. Check the technical specification sheet of the timer relay for parameters such as rated voltage, rated current, and time delay.

- Safety Measures: When testing the timer relay, make sure you have taken appropriate safety measures such as disconnecting the power supply to avoid electric shock or electrocution.

- Connecting Relay: Connect the timer relay to an appropriate power source and test equipment. Make sure the connections are correct to prevent short circuits or other problems.

- Setting Time: Set the time delay for the timer relay according to your testing needs. This can usually be accomplished with a knob, button, or digital panel on the timer relay.

- Input Signal: Provide an appropriate input signal to activate the timer relay. This can be a voltage, current, or digital signal depending on how the timer relay operates.

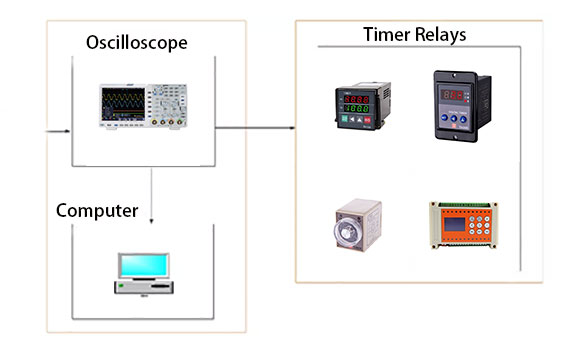

- Test Output: Observe the output action of the timer relay to ensure that the timer relay triggers within the set time delay. You can use an oscilloscope, multipurpose meter, or other relay tester equipment to monitor the output signal.

- Test Several Times: Repeat the test several times to ensure consistency and reliability of the results. This helps to rule out chance errors.

- Record Results: Record the results of the test, including the set time delay and actual trigger time. These records can be used for comparison and analysis.

- Analyze the Results: Analyze the test results to ensure that the performance of the timer relay meets the specifications. If there are deviations or problems, maintenance or calibration may be required.

- Maintenance and Calibration: Timer relays may require periodic maintenance and calibration to ensure performance and accuracy. Follow the manufacturer's recommendations for maintenance and calibration.

Test Methods and Equipment

- Oscilloscope: An oscilloscope is a device used to observe signal waveforms and can be used to monitor the output signals of timer relays and measure time delays.

- Multi-purpose Meter (Dometers): Multi-purpose meters can be used to measure voltage, current, and resistance to monitor the input and output signals of timer relays.

- Frequency Meter: A frequency meter can be used to measure the frequency of an output signal to determine the time delay of a timer relay.

- Standard Clocks: Standard clocks can be used to compare the time delays of timer relays to evaluate their accuracy.

- Automated Test Equipment (ATE): An ATE system allows for automated testing and efficient batch testing of multiple timer relays.

Precautions and Frequently Asked Questions

- Prioritize Safety: Always ensure safety to avoid electric shock, electrocution, or other potential risks.

- Follow Manufacturer's Guidelines: Follow the timer relay manufacturer's test and maintenance guidelines to ensure proper operation.

- Constant Temperature Environment: Maintain a stable temperature environment when testing timer relays, as temperature variations may affect relay performance.

- Calibration: Calibrate test timer relays periodically to ensure accurate test results.

- Multiple Tests: Repeat the tests several times to verify the stability and reliability of the timer relays.

- Records and Documentation: Record all test results and maintenance logs to track the relay's performance history.

Testing timer relays is a critical step in ensuring the reliable operation of electrical systems. Best timer relays play an important role in industrial, power, automation, and control systems, and their accuracy is critical to safety, equipment protection, productivity, and system stability. Following proper testing procedures, methods, and precautions will ensure the reliability of timer relays and improve the reliability and safety of electrical systems. Careful testing and maintenance will help ensure that timer relays perform well in their critical applications.