Self Priming Pump Working Principle

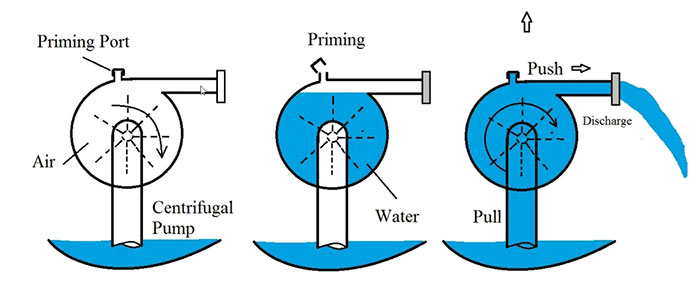

The self priming pump is a common centrifugal pump, and its self priming principle involves using centrifugal force to draw liquid into the pump from a lower point and expel it. The self priming principle of the pump can be divided into three stages: liquid introduction, negative pressure establishment, and liquid pumping. In this article, ATO Industrial Automation will briefly introduce them to you.

Working Principle of Self Priming Pump

The first stage, liquid introduction, refers to the self priming pump using gear pumps or vortex pumps to further introduce liquid, filling the pump's interior with liquid. When there is no liquid inside the self priming pump, the rotation of the pump shaft causes the impeller inside the pump to rotate, creating a certain vacuum inside the pump. When the liquid supply is restored, the liquid flows into the pump through the inlet pipe. As the liquid passes through the pump shaft and impeller, it undergoes high-speed rotation, moving along the axis due to centrifugal force, and finally exits from the pump's discharge outlet. The key to this stage is to introduce enough liquid to fill the pump chamber.

Next, the negative pressure establishment stage involves maintaining a vacuum inside the pump by using centrifugal force to draw liquid into the pump through the inlet pipe when the pump's interior is filled with liquid. After introducing the liquid into the pump, as the liquid flows outward due to centrifugal force, a portion of the liquid in the inlet pipe moves into the pump, forming a liquid film under the action of centrifugal force. When the film reaches the impeller outlet, the impeller pushes it further into the pump. At this point, a vacuum is formed inside the pump due to the decrease in pressure, and the liquid continues to move into the pump. With a continuous supply of liquid, negative pressure can be established and maintained at a certain value over time.

Finally, the liquid pumping stage is when the vacuum inside the self priming pump reaches a certain level, and the liquid is pushed to the pump outlet by centrifugal force. In this stage, as negative pressure continues to be established, the liquid source continuously replenishes the liquid inside the pump, and the liquid is also pushed to the pump inlet by the rotation of the impeller. When the liquid is pushed to the pump outlet by centrifugal force, the pressure of the liquid increases, overcoming pipeline resistance, allowing the liquid to flow smoothly. At the same time, during the rotation of the liquid through centrifugal force, the inertia causes the liquid to form a high-speed rotation, creating a vortex, further increasing the ability to pump out the liquid.

In summary, the self priming principle of the pump mainly includes three stages: liquid introduction, negative pressure establishment, and liquid pumping. Through the action of centrifugal force and vacuum, the liquid is automatically drawn into the pump from a lower point and pushed to the pump outlet, realizing the pumping function. This self priming principle allows the self priming pump to automatically draw water and drain without the need for external water intake, making it widely used in engineering, agriculture, and daily life.

Applications of Self Priming Pump

- Industrial self priming water pumps are suitable for urban environmental protection, construction, fire protection, chemical industry, pharmaceuticals, dyes, printing and dyeing, brewing, power, electroplating, papermaking, petroleum, mining, equipment cooling, oil tanker unloading, etc.

- Industrial self priming water pumps are suitable for clear water, seawater, and chemical media with acidity and alkalinity, as well as general slurry media with a viscosity ≤100 centipoise and solid content up to 30%.

- Industrial self priming water pumps, equipped with rocker-type nozzles, can spray water into the air and disperse it into fine droplets for misting, making them excellent equipment for farms, nurseries, orchards, and tea gardens.

- It can be used in conjunction with any model or specification of filter press to send slurry to the filter press for filtration. It is the most ideal pump for pressurized filtration, with the advantage of strong sewage discharge capability, a self priming height 1 meter higher than a general self priming pump, and a shorter self priming time.

In summary, the self priming pump's three-stage process, driven by centrifugal force and vacuum, allows for automatic liquid intake and efficient pumping. Its versatility spans industries, from environmental protection to agriculture, offering a reliable and autonomous solution for fluid handling. With strong sewage discharge capabilities and suitability for pressurized filtration, the self priming pump emerges as a vital tool, underlining its crucial role in diverse applications across sectors.