Tantalum Capacitor: Definition, Advantages and Comparison

The full name of tantalum capacitor is tantalum electrolytic capacitor, which is a kind of electrolytic capacitor. It uses tantalum metal as the medium instead of electrolyte as common electrolytic capacitor. In this article, we will introduce what tantalum capacitor is, what advantages tantalum electrolytic capacitor has, and the comparison with ceramic capacitor.

What is a Tantalum Capacitor?

Tantalum electrolytic capacitors are a subtype of electrolytic capacitors. They are made of tantalum metal that acts as an anode, covered with an oxide that acts as a dielectric, and surrounded by a conductive cathode. The use of tantalum makes the dielectric layer very thin. This results in higher capacitance per volume values, superior frequency characteristics and superior stability over time compared to other types of capacitors. Tantalum capacitors are usually polarized, which means they may only be connected to a DC power source by observing the correct terminal polarity.

A SMD tantalum capacitor includes tantalum metal as an anode, enclosed in an anodic oxide layer of oxide, acting as a dielectric, which is further wrapped by a liquid or solid electrolyte as a cathode.

The disadvantage of using tantalum capacitors is their unfavorable failure mode, which can lead to thermal runaway, fires, and small explosions, but this can be prevented by using external fail-safe devices such as current limiters or thermal fuses. The most common form is surface mount device (SMD). These surface mount tantalum capacitors require less space on the printed circuit board and allow greater packing density. Tantalum capacitors are very stable, smaller and lighter, with lower maximum operating voltage and capacitance.

Advantages of Tantalum Capacitor:

Tantalum capacitors have the advantage of excellent performance. Tantalum chip capacitors are small in size, but can achieve larger capacitances. Low ESR (equivalent series resistance) tantalum capacitors are the best choice for applications such as power filtering and AC bypassing. Tantalum capacitors use a unique process that allows them to operate in a wide temperature range, ranging from minus 55 degrees to 125 degrees. In addition, tantalum capacitors have good stability, high precision and small size. This capacitor is made of oxide film to strengthen the dielectric and restore its insulating ability. therefore. It has a unique self-healing function.

Tantalum capacitors have stable performance. In addition, tantalum capacitors have the advantages of high precision and good high-frequency filtering effect. Tantalum capacitors are generally used in circuits that require high capacitance stability. We can see its application on computer motherboards, graphics cards or mobile phones.

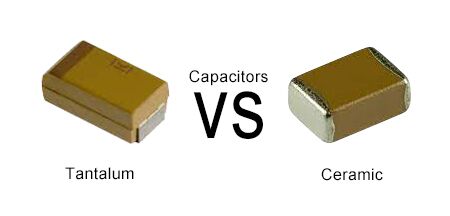

Ceramic vs. Tantalum Capacitor:

- Aging. Ceramic capacitors tend to age faster than tantalum capacitors. Tantalum capacitors do not have a known wear-out mechanism.

- Polarization. Tantalum capacitors are polarized, which means that they can only be connected to a DC supply and maintain the right terminal polarity. In contrast, ceramic capacitors are non-polarized, and you can easily connect them to an AC source.

- Temperature response. Tantalum capacitors show a linear change in capacitance when subjected to temperature changes, while general ceramic capacitors usually show a non-linear response.

- Voltage response. Tantalum capacitors show consistent stability with change in applied voltage, whereas ceramic capacitors do not.