What is a Bearing?

A bearing is a common mechanical component widely used in various machinery. It is a device capable of reducing friction, supporting, and positioning rotating shafts. Bearings provide crucial support and facilitate the movement of rotating or moving parts, playing a vital role in carrying and transmitting forces in mechanical equipment. In this article, ATO industrial automation will introduce the basic information about the bearing (including structure, type, and its functions) for you.

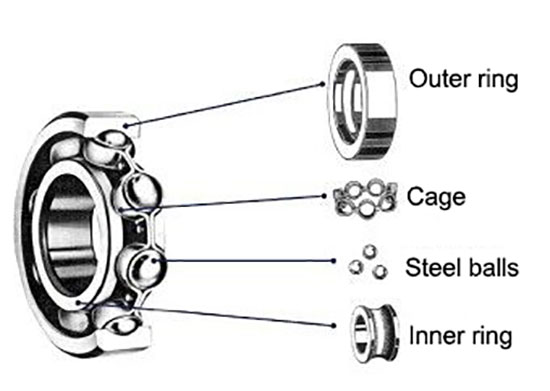

Structure of Bearings

The basic structure of a bearing includes four components: the inner ring, outer ring, rolling elements, and the cage. The inner and outer rings are the main load-bearing parts of the bearing, while the rolling elements bear the load and rotational forces. The cage fixes the position of the rolling elements, allowing them to maintain a certain gap and relative position.

The inner ring is the inner circular part of the bearing, typically made of steel or cast iron. Its primary function is to support the inner shaft of the bearing, ensuring smooth rotation. The outer ring, also made of steel or cast iron, supports the external load of the bearing and closely matches the bearing seat to stabilize the bearing during operation.

The rolling elements are the core part of the bearing, usually made of materials such as steel balls, steel columns, or rollers. Their main function is to bear the internal load and rotational forces of the bearing, allowing smooth rotation through rolling.

The cage, typically made of steel or plastic, fixes the position of the rolling elements. Its main role is to maintain the gap and relative position of the rolling elements, ensuring the stability and durability of the bearing.

Classification of Bearings

- Sliding Bearings:

Sliding bearings have no inner or outer rings and lack rolling elements. They are typically made of wear-resistant materials and are commonly used in low-speed, heavy-load applications where lubrication and maintenance are challenging. - Roller Bearings:

Roller bearings are classified based on the direction of the load they can bear or the nominal contact angle. They include radial bearings and thrust bearings. Radial contact bearings have a nominal contact angle of 0 and are used for radial loads. Angular contact bearings have a nominal contact angle greater than 0 but less than 45 and are used for combined radial and axial loads. Thrust contact bearings have a nominal contact angle of 90 and are used for axial loads. Angular thrust contact bearings have a nominal contact angle greater than 45 but less than 90. - Linear Slide Bearings:

Linear slide bearings are a cost-effective linear motion system used in conjunction with cylindrical shafts for infinite travel. Due to the point contact between the bearing balls and the shaft, they carry light loads. The steel balls rotate with minimal friction, providing high-precision smooth motion. - Turntable Bearings:

Turntable bearings are large bearings with a special structure capable of simultaneously bearing large axial loads, radial loads, and overturning moments. They integrate various functions such as support, rotation, and fixing. These bearings are widely used in large rotating devices such as lifting and transport machinery, mining equipment, construction machinery, port machinery, wind power generation, medical equipment, radars, and other large rotary devices.

Functions of Bearings

- Friction Reduction:

Bearings provide a lubricating medium between the rotating shaft and the support, reducing friction and wear. Through the action of bearings, mechanical equipment operates more smoothly, resulting in decreased energy consumption and wear. - Supporting Force:

Bearings can support the weight of the rotating shaft, maintaining its rotation in the correct position. They withstand forces from both the rotating shaft and the applied load, ensuring stable operation of mechanical equipment. - Positioning of the Rotating Shaft:

Bearings enable the precise positioning and orientation of the rotating shaft, ensuring the operational accuracy and stability of mechanical equipment. Through various structures and designs, bearings accurately locate the position of the rotating shaft, preventing axial displacement and oscillation. - Power Transmission:

Bearings can withstand forces from both the rotating shaft and the load, enabling the transmission of power and torque. Through the action of bearings, mechanical equipment achieves power transmission and rotation.

In summary, bearings are indispensable components in mechanical equipment, serving to reduce friction, provide support and positioning for the rotating shaft, and facilitate power transmission. They play a crucial role in various industries, including automotive, aerospace, and industrial machinery.