What is a Film Capacitor?

There are many types of capacitors depending on the medium, such as electrolyte capacitors, tantalum capacitors, film capacitors, ceramic capacitors, mica capacitors, air conditioner capacitors, etc. However, electrolytic capacitors and film capacitors are the most frequently used in audio equipment. In this article, ATO Store will mainly introduce you to the basic knowledge of the structure, working principle, advantages, applications, and other aspects of film capacitors.

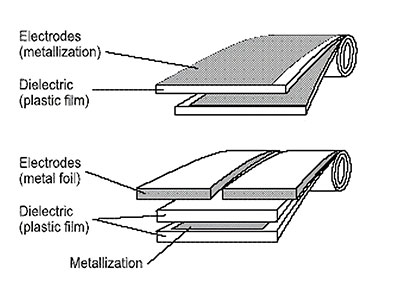

Structure of Film Capacitors

The main structure of film capacitors includes two electrodes and a dielectric film. Electrodes are usually made of metal materials, such as aluminum, silver, etc. Dielectric films can be insulating materials such as aluminum oxide, silicon nitride, etc. The electric field formed between the electrode and the film is the core part of the film capacitor.

Working Principle of Film Capacitors

Film capacitors work on the same principle as general capacitors, they are stored on the electrode charge storage of electrical energy, usually used in conjunction with an inductor to form an LC oscillator circuit, capacitors work on the principle of charge in the electric field will be subjected to the force and move, when the conductor between the medium, it impedes the movement of the charge and make the charge accumulated in the conductor, resulting in the accumulation of charge storage.

Advantages of Film Capacitors

- Small change in capacitance due to temperature change

The dielectric constant of the ceramic capacitor dielectric and the electrostatic capacitance of the capacitor change with temperature changes. In addition, aluminum electrolytic capacitors, the conductivity of the electrolyte and the resistance of the electrode will change with the temperature change, and thus the electrostatic capacitance will also change. Ceramic capacitors and aluminum electrolytic capacitors, its electrostatic capacitance will change with the temperature change and more than 10% change, while the same temperature range by the film capacitor electrostatic capacitance only a few percent change. - High insulation resistance

Film capacitors use PP (polypropylene), PET (polyethylene terephthalate), PPS (polyphenylene sulfide), and PEN (polyethylene terephthalate) as the dielectric, and are characterized by higher insulation resistance and a better ability to maintain the saved electricity than ceramic capacitors and aluminum electrolytic capacitors. The insulation resistance of capacitors generally decreases with increasing temperature, but compared to other capacitors, the insulation resistance of film capacitors is less likely to decrease even when the temperature increases, thus maintaining performance. - Fewer failures and longer life

Plastic film as a dielectric for film capacitors is characterized by fewer failures and longer life than other capacitors due to its stable physical properties. - No change in bias characteristics

While the electrostatic capacitance of ceramic capacitors changes with the applied voltage, the electrostatic capacitance of film capacitors hardly changes with the applied voltage. Utilizing this characteristic, film capacitors have the advantage of less distortion and improved sound quality when used in audio circuits. - Excellent withstanding voltage and ripple current characteristics

Aluminum electrolytic capacitors have an withstand voltage of about 500V, but film capacitors can be manufactured to handle high withstand voltages of nearly 4000V. Inverter power supplies are used to handle high voltages of 650V for solar power generation systems, 48 to 750V for HEVs, and 1,000 to 3,000V for railroad vehicles. Film capacitors are indispensable for stabilizing the voltage of the inverter power supply (noise removal, smoothing). Film capacitors also have excellent ripple current resistance (allowable current) and are not prone to self-heating even when large currents flow through them.

Applications of Film Capacitors

Film capacitor is a common electronic component, widely used in various electronic devices. It has the advantages of small size, light weight, low cost and high reliability, so it is widely used in the electronics industry.

- Film capacitors play an important role in communication devices.

Film capacitors are used for touch screens in devices such as cell phones, tablet PCs, and TVs. By coating the film with conductive material, a capacitive structure is formed, and when the user touches the screen, the capacitance changes, thus realizing the control of touch. Film capacitive touch screen has the advantages of high sensitivity, high resolution, fast response, etc., and has become an indispensable and important part of modern electronic equipment. - Film capacitors are widely used in electronic computer equipment.

Film capacitors are used for voltage stabilization and filter design on circuit boards such as computer motherboards and graphics card memory. Film capacitors are able to stabilize the output voltage through the principle of capacitance, providing a stable power supply to other electronic components. At the same time, film capacitors can also be used for signal filtering, removing interfering signals in the circuit and improving the working stability of the equipment. - Film capacitors also play an important role in audio equipment.

Film capacitors are used for sound conversion and amplification in headphones, stereos, speakers and other devices. Film capacitors generate sound by vibrating the film, convert the sound signal into electrical signal through the change of capacitance, and then amplify and output it to speakers through amplifiers, so that people can enjoy high-quality music and sound effects. The high sensitivity and fast response capability of film capacitors make the sound quality of audio equipment clearer and more detailed. - Film capacitors are also widely used in lighting equipment.

Film capacitors are used for power management and drive control in devices such as LED lights and liquid crystal displays. Film capacitors can stabilize the output current and voltage to ensure the normal operation of LED lights or LCDs. At the same time, film capacitors are also able to control the brightness and color of LED lights or LCDs through changes in capacitance, making the lighting equipment have the function of dimming and color adjusting to meet people's different needs.

As an important electronic component, film capacitor plays an important role in communication equipment, electronic computer equipment audio equipment and lighting equipment. Its small, lightweight, low-cost features, making electronic devices become more intelligent, convenient and efficient. With the continuous progress of science and technology and innovation, it is believed that film capacitors in the future application areas will be more extensive for people's lives to bring more convenience and fun.