What is Tantalum Capacitor Failure Mode?

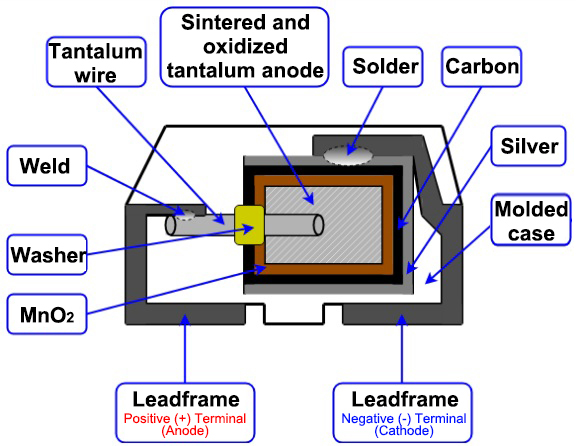

Tantalum (Ta) is a silver-gray metal with the atomic number 73. When looking at a cross-sectional view of a tantalum capacitor, such as a standard SMD tantalum electrolytic chip capacitor with solid electrolyte shown in the figure below, the positive (anode) terminal is tantalum powder pressed and sintered into a pallet. The dielectric is formed by an insulating oxide layer covering the positive (anode) terminal, and the negative (cathode) terminal is formed by a solid manganese dioxide electrolyte.

We not only know the features of tantalum capacitor, in this article, ATO industrial automation will mainly introduce failure mode of tantalum capacitor.

In the case of solid tantalum capacitors, the electrolyte is added to the anode through pyrolysis. In order to make manganese dioxide coating, solid tantalum capacitors are immersed in a special solution and baked in an oven. Repeat this process until there is a dense coating on the inner and outer surfaces of the pellets. Finally, in order to ensure a strong cathode connection, the particles used in solid tantalum capacitors are immersed in graphite and silver. Unlike solid tantalum capacitors, wet tantalum capacitors use liquid electrolytes. After the anode is sintered and the dielectric layer is grown, it is immersed in the liquid electrolyte in the shell. In wet tantalum capacitors, the shell and electrolyte act as the cathode.

Tantalum capacitors have a high capacitance per volume and weight due to their thin, high permittivity dielectric sheet, which sets them apart from other electrolytic capacitors. Tantalum electrolytic capacitors are also ideal for passing or bypassing low-frequency signals and storing significant quantities of electric energy due to their large capacitance.

3 Failure Modes of Tantalum Capacitor:

- High Leakage / Short. High leakage currents may result from applying reverse voltage, which is common during troubleshooting, malfunctions, and/or bench testing. Since the hotspots formed during crystallization heat the cathode, tantalum capacitors with crystallization cause short circuit failure.

- High Equivalent Series Resistance (ESR). When a capacitor is exposed to board mounting, pick-and-place, reflow, and operation lifetime, the mechanical/thermomechanical has a significant impact on its ESR. External and/or internal relations are often harmed as a result of this form of stress, resulting in a high ESR.

- Low Capacitance / Open. The failure is uncommon since the capacitance of a chip tantalum capacitor does not shift under normal operating conditions. A tantalum capacitor's lower capacitance in any application may indicate a shorted capacitor, while an open failure can be caused by a damaged positive lead and wire link.

As we all know, tantalum electrolytic capacitors have a potentially dangerous failure mode. The tantalum anode may come into contact with the manganese dioxide cathode during voltage spikes, and if the energy of the spike is adequate, a chemical reaction may start. This chemical reaction generates heat and is self-sustaining, as well as the possibility of smoke and flame. External failsafe circuitry, such as current limiters and thermal fuses, should be used in combination with tantalum capacitors to avoid thermal runaway.