What is a Programmable Logic Controller?

Programmable Logic Controllers (PLCs) have become indispensable in the realm of automation and control systems. These specialized devices play a crucial role in ensuring the seamless operation of various industrial processes. In this comprehensive blog post, we will delve into the fundamentals of PLCs, exploring their architecture, functions, applications, and the pivotal role they play in modern industries.

Basic Knowledge

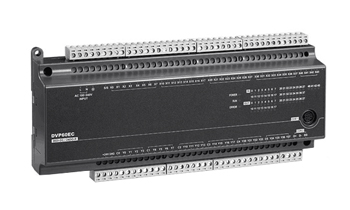

A Programmable Logic Controller (PLC) is a digital computing controller equipped with a microprocessor, designed for automated control. It can load and store control instructions in memory for execution at any time. A PLC comprises a Central Processing Unit (CPU), instruction and data memory, input/output interfaces, power supply, digital-to-analog converters, and other functional units. In its early stages, PLCs were primarily focused on logic control, hence the name "Programmable Logic Controller." However, as they evolved, these initially simple computing modules incorporated various functions, including logic control, sequential control, analog control, and multi-machine communication. The term "Programmable Controller" emerged as a more inclusive name, but due to the abbreviation conflict with "Personal Computer" (PC), and due to convention, people often continue to use the term "Programmable Logic Controller" (PLC) along with the acronym PLC.

Basic Structure

- Power Supply: The power supply is used to convert alternating current (AC) into the direct current (DC) required for the internal operations of the PLC. Most PLCs utilize a switched-mode voltage regulator for power supply.

- Central Processing Unit (CPU): The Central Processing Unit (CPU) serves as the control center and core component of the PLC, determining its overall performance. The CPU consists of a controller, arithmetic logic unit, and registers, all integrated on a single chip. It is interconnected with the input/output interface circuits of the memory through the address bus and control bus. The CPU's role is to process and execute user programs, perform logical and mathematical operations, and control the entire system for coordination.

- Memory: Memory is a semiconductor circuit with memory functions, responsible for storing system programs, user programs, logical variables, and other information. System programs control the various functions of the PLC and are written by the PLC manufacturer, typically embedded in read-only memory (ROM), inaccessible to users.

- Input Unit: The input unit is the interface connecting the PLC to the controlled devices, serving as the bridge for signals entering the PLC. Its function is to receive signals from main control elements and detection elements. Input types include direct current input, alternating current input, and AC/DC input.

- Output Unit: The output unit is also a connecting component between the PLC and controlled devices. Its role is to transmit PLC output signals to the controlled devices, converting the low-voltage signals from the central processing unit into level signals to drive the execution elements of the controlled devices. Output types include relay output, transistor output, and thyristor output.

In addition to the aforementioned components, PLCs may have various external devices depending on the model, aiding in programming, monitoring, and network communication. Common external devices include programmers, printers, cassette tape recorders, computers, and more.

Fratures

- High Reliability: Due to the widespread use of single-chip microcomputers in PLCs, their high integration, coupled with protective circuits and self-diagnostic functions, enhances system reliability.

- Easy Programming: PLC programming often utilizes relay control ladder diagrams and command statements. The number of instructions is much less than that of microcomputers, typically around 16 for small PLCs, except for mid to high-end models. The graphical representation of ladder diagrams makes programming easy to grasp and user-friendly, requiring minimal computer expertise.

- Flexible Configuration: PLCs adopt a modular structure, allowing users to easily combine components to flexibly alter the functionality and scale of control systems. As a result, PLCs can be applied to various control systems.

- Comprehensive Input/Output Function Modules: One of the significant advantages of PLCs is the availability of templates for different field signals (such as DC or AC, digital or analog, voltage or current, etc.). These templates can be directly connected to industrial devices (such as buttons, switches, current transmitters, motor starters, or control valves) and linked to the CPU motherboard via a bus.

- Convenient Installation: In comparison to computer systems, PLCs do not require dedicated rooms or strict shielding measures. During usage, connecting detection devices and executive mechanisms to the I/O interface terminals of the PLC is sufficient for normal operation.

- Fast Operation: Since PLC control is executed by programmed instructions, both reliability and operational speed surpass those of relay logic control.

Programmable Logic Controllers (PLCs) stand as the cornerstone of modern industrial automation, seamlessly orchestrating complex processes across various sectors. As we've explored the fundamentals of PLCs, delving into their architecture, programming languages, functions, and applications, it becomes evident that these devices are pivotal in ensuring efficiency, precision, and reliability in industrial operations. For more information on PLC go to ATO.com.