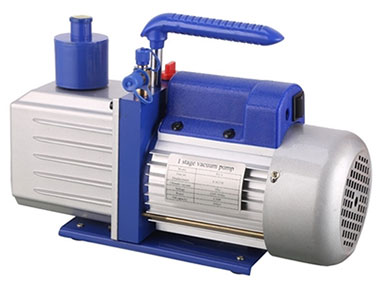

What is a Rotary Vane Vacuum Pump Used for?

A rotary vane vacuum pump one of the four main types of rotary pumps, in current society a vane pump has many usages, such as agricultural production, industrialization or transportation industry, etc. Next we will learn the definition of rotary vane vacuum pump and what it can be used for.

What is a Rotary Vane Vacuum Pump

The definition of rotary vane vacuum pump is a positive displacement pump, vanes installed inside the cavity rotating  rotor constitute the main body. Vane pump is a two-stage structure, composed of high pressure level and low ones two parts. In some cases, the vane has the function of controlling the length and keeping in contact with the wall when the pump rotates. The principle of its work is that when the equipment obtains vacuum, the high pressure stage exhaust valve will be closed, and the gas inhaled by the high pressure stage will be transferred to the second stage, inhaled and discharged through the second stage, so that the vacuum equipment can obtain a certain vacuum. According to the user's own demand, it can be equipped with vacuum booster pump, and the pump will be used as the pre-stage pump, because the pumping force of the booster pump is strengthened, resulting in the continuous pumping out of the pre-stage pump, so the equipment can obtain a higher vacuum space.

rotor constitute the main body. Vane pump is a two-stage structure, composed of high pressure level and low ones two parts. In some cases, the vane has the function of controlling the length and keeping in contact with the wall when the pump rotates. The principle of its work is that when the equipment obtains vacuum, the high pressure stage exhaust valve will be closed, and the gas inhaled by the high pressure stage will be transferred to the second stage, inhaled and discharged through the second stage, so that the vacuum equipment can obtain a certain vacuum. According to the user's own demand, it can be equipped with vacuum booster pump, and the pump will be used as the pre-stage pump, because the pumping force of the booster pump is strengthened, resulting in the continuous pumping out of the pre-stage pump, so the equipment can obtain a higher vacuum space.

Adjust Air Pressure to Separate Liquid

Because of their powerful pumping capacity, vane vacuum pumps are commonly used as high-pressure hydraulic pumps, including boosting, power steering, air conditioning and automatic transmission pumps, or medium-pressure pumps can be used as fountain soft drink dispensers and carbonators for espresso machines, and so on. In addition, vane vacuum pumps can also be used for low-pressure gas applications, such as secondary air injection for automotive exhaust emission control, or for low-pressure chemical vapor deposition systems. The rotary vane pump is a common type of vacuum pump, the two stages capable of reaching pressures far below 10-6 bar. The pumped gas and oil are mixed inside the pump, so they must be separated externally. Therefore, the inlet and outlet have a large chamber, perhaps with swirls, where oil droplets fall from the gas. Sometimes the inlet has louvers cooled by the room air (pump temperature is usually 40K) to condense the broken pump oil and water and let it fall back to the inlet.

Industrial Oil Transportation

Rotary vane vacuum pumps can be used in industrial oil transportation. Inside the vane vacuum pump there is a force between the rotor and the stator that is biased and the vanes can slide flexibly in the grooves of the rotor. Under the action of the centrifugal force of the rotor rotation and the influence of pressure oil passed into the root of the vane, the rotor in the vane pump rotates with the tip pressed against the inner surface of the stator, which is able to compress the air in the chamber to generate suction, so that the two vane with the rotor and the inner surface of the stator constitute a certain working volume. Due to the influence of centrifugal force, moving in and out along the inner surface of the casing, thus pumping air molecules from the container or area, relying on the working elements in the pump cylinder for reciprocating or rotary motion, the working volume alternately increases and decreases, this spatial volume change forces the liquid to be transferred from the suction port to the discharge channel. In the oil transportation, vane pump first from small to large oil suction and then from large to small oil discharge, vane rotation a week, complete a suction and discharge of oil.

Agricultural Water Irrigation

Vane vacuum pump can also be used in agricultural irrigation. Vane vacuum pumptransporting water is called axial flow pump, there are 2 to 7 vane rotation in the circular tube-shaped pump casing. Its working principle is the upper part of the impeller pump casing is equipped with a fixed guide vane, which role is to eliminate the rotational motion of the liquid, so that it becomes axial motion, and the kinetic energy of the rotational motion transform into pressure energy. If the wing-shaped paddle is fixed on the shaft to form a propeller, and make it can’t move along the axial direction, then when the shaft rotates at high speed, the wing surface (the lower side of the propeller) due to negative pressure and suction flow, the back of the wing due to positive pressure and discharge, so a suction and discharge result in the flow of liquid (or gas).

More Usages

The rotary vane vacuum pump can also be widely used in daily life such as refrigerators, air conditioners, light bulbs, oil filters and other industrial vacuum smelting, vacuum welding, vacuum impregnation, vacuum coating, vacuum heat treatment, vacuum drying, vacuum packaging and other processes.