What is Bilge Pump Type?

When it comes to boating, safety is paramount. One crucial component of a boat's safety equipment is the bilge pump. A bilge pump is designed to remove water that accumulates in the bilge, the lowest part of the boat. However, not all bilge pumps are created equal. There are different types of bilge pumps, each with its unique features and advantages. In this blog, we will explore the various bilge pump types, helping you make an informed decision on the best one for your boat.

Manual Bilge Pumps

- Operation: Manual bilge pumps are operated by hand, typically using a lever or a handle. Boat owners or crew members physically pump the handle to remove water from the bilge.

- Advantages: These pumps are simple, reliable, and don't rely on electricity. They can be used as a backup in case of power failure. They are also relatively inexpensive.

- Disadvantages: Manual pumps require physical effort to operate and may not be as efficient as electric pumps, especially for larger vessels or in emergency situations.

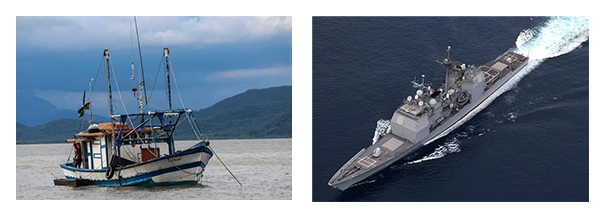

- Applications: Manual bilge pumps are commonly used on smaller boats, canoes, and kayaks. They are suitable for vessels where electrical power may not be available or where a backup pumping method is required. Manual pumps are often used for routine maintenance to remove smaller amounts of water or as an emergency backup on larger vessels.

Electric Submersible Bilge Pumps

- Operation: These pumps are electrically powered and are typically installed in the bilge. They automatically activate when a float switch or electronic sensor detects water in the bilge.

- Advantages: Electric submersible pumps are convenient and efficient. They can quickly remove water without the need for manual intervention. They are suitable for boats of various sizes and are available in different capacities.

- Disadvantages: They rely on electrical power and may be less reliable in the event of a dead battery or electrical failure.

- Applications: Electric submersible pumps are versatile and suitable for a wide range of boats, from small sailboats to large yachts and powerboats. They are ideal for vessels with electrical systems, as they automatically remove water without human intervention. These pumps are also commonly used in smaller boats with limited storage space for manual pumps.

Diaphragm Bilge Pumps

- Operation: Diaphragm pumps use a rubber diaphragm to create a pumping action. When the diaphragm flexes, it generates a vacuum, drawing water into the pump, and then flexes in the opposite direction to expel the water.

- Advantages: Diaphragm pumps are self-priming and can handle a variety of fluids, including those with solid particles. They are suitable for small to medium-sized boats.

- Disadvantages: They can be sensitive to debris and may require periodic maintenance.

- Applications: Diaphragm pumps are well-suited for boats in the mid-range size category. They are effective at handling water with a moderate amount of debris or solid particles. Diaphragm pumps are often used in fishing boats, smaller cruisers, and some medium-sized sailboats.

Centrifugal Bilge Pumps

- Operation: Centrifugal pumps use an impeller to draw water into the pump and expel it through an outlet. They rely on centrifugal force to move water.

- Advantages: These pumps are efficient and can handle relatively large volumes of water. They are suitable for larger vessels.

- Disadvantages: Centrifugal pumps are not as effective at removing water with high solids content, and they may not work well with very low water levels.

- Applications: Centrifugal pumps are suitable for larger vessels, including commercial ships, larger sailboats, and powerboats. They can efficiently handle higher volumes of water, making them well-suited for vessels with greater bilge capacities. However, they may not be ideal for removing water with a high solid content.

Air-Operated Bilge Pumps

- Operation: Air-operated pumps use compressed air to create a vacuum and draw in water. They are commonly used in industrial and commercial settings.

- Advantages: These pumps are suitable for hazardous or explosive environments and can handle a wide range of fluids.

- Disadvantages: They require a source of compressed air, which may not be readily available on all boats.

- Applications: Air-operated bilge pumps are commonly found in industrial and commercial marine applications, such as oil tankers, large cargo ships, and vessels that transport hazardous materials. They are chosen for their ability to handle a wide range of fluids, including chemicals, and their suitability for potentially explosive environments.

Understanding the different types of bilge pumps allows boat owners to select the most appropriate pump for their vessel's size, purpose, and specific needs, ensuring effective water removal and enhancing the safety of their boating experience.

Selecting the right bilge pump for your boat is a crucial decision that can greatly impact your safety on the water. Consider the size of your boat, the amount of water you anticipate dealing with, and your budget when choosing the best bilge pump type. Whether you opt for a manual pump for a small dinghy or a powerful electric submersible pump for a larger vessel, ensuring you have a reliable bilge pump is an essential part of responsible boating. In addition, the ATO store also offers other types of pumps, welcome to browse.