What is Magnetic Drive Pump?

The magnetic drive pump is a new type of sealless pump that uses the principle of permanent magnet transmission technology to achieve contactless transmission of torque. There is no mechanical connection between the driving shaft and the driven shaft, and no dynamic seal is required in the structure. Therefore, this type of pump has no seal and can achieve zero leakage. The magnetic drive pump is especially suitable for transporting flammable, explosive, volatile, toxic, and hazardous materials. For corrosion and precious liquids, magnetic pumps are mostly used in situations where the magnetic drive pump can only leak slightly or even without leakage, as well as in high vacuum situations where mechanical seals are difficult to handle.

Basic Introduction

The magnetic drive pump is a positive displacement gear pump that uses a magnetic actuator to achieve contactless torque transmission and replaces the dynamic seal with a static seal, making the magnetic drive pump completely leak-free. The magnetic drive pump uses a magnetic coupling to isolate the transmission and is generally a rotary working pump. Half of the magnetic coupler (the inner magnet) is mounted on the magnetic drive pump shaft and sealed in the pump body with an isolation cover made of non-ferromagnetic material.

The other half (outer magnet) is installed on the magnetic drive pump motor shaft, and the inner magnet is driven by a magnetic force outside the isolation cover to rotate and drive the magnetic drive pump to work, so there is no leakage. The bearings are made of self-lubricating materials and lubricated by the sent liquid. The magnetic drive pumps are suitable for transporting toxic and harmful, flammable, explosive, highly corrosive, and valuable liquids that do not contain particles. The magnetic drive pump adopts an independent lubrication system and is isolated from the liquid being sent. It is suitable for transporting granular, slurry-like materials and high-temperature liquids (450°C).

Structural Principles

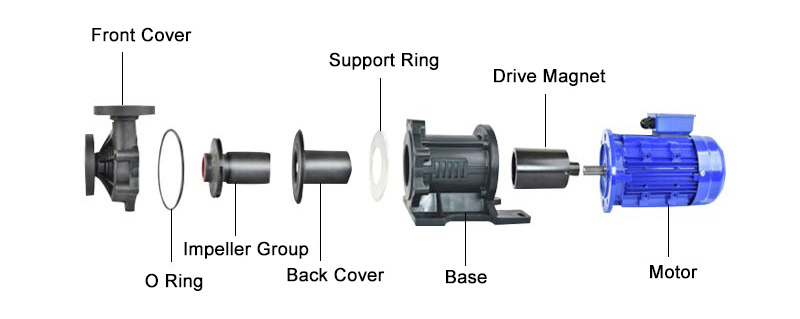

Magnetic drive pumps use magnets to attract ferromagnetic substances and there is a magnetic force between magnets or magnetic fields. Non-ferromagnetic substances do not affect or rarely affect the magnitude of the magnetic force, so the can pass through non-magnetic conductors (isolation sleeves) without contact. Characteristics of power transmission. The magnetic drive pump is mainly composed of a pump body, an impeller, a magnetic coupling, an isolation sleeve, an electric motor, etc.

The magnetic drive pump motor is connected to the external magnet through a coupling. The impeller and inner magnet are integrated through the impeller nut and the inner shaft of the magnetic drive pump and are installed in a sealing body composed of the pump body and an isolation sleeve. The motor drives the outer magnet, and the outer magnet drives the inner magnet to rotate the impeller, thereby replacing the dynamic seal with a static seal to achieve leak-free transmission of the medium.

Component

- The magnetic drive pump body and impeller are basically the same as ordinary pumps, and serve the purpose of working on the fluid and collecting and transporting the fluid after the work has been done.

- The cylindrical magnetic coupling is composed of inner and outer magnetic rotors and isolation sleeves. It serves the purpose of transmitting force or torque in space and is a key transmission component in the magnetic drive pump.

- Sliding bearings and thrust bearings support and axially limit the rotor components such as the impeller, pump shaft, and internal magnetic rotor. It is a key component in the magnetic pump, and its performance directly affects the service life of the magnetic pump.

- The main connector is the coupling support component in the magnetic pump. Mainly plays the role of connection and positioning.

- The bearing suspension component supports the drive shaft that drives the external magnetic rotor. Only exists in non-direct structures.

- The prime mover is usually an electric motor. Power the magnetic drive pump.

Typical Structural Classification

According to the Motor Connection Method

The external magnetic rotor of the direct-coupled structure is driven by the magnetic drive pump motor shaft for active rotation. The prime mover adopts a direct-coupled motor with a B35 connection method. The advantage is that the magnetic drive pump has a compact structure and a small space volume. The disadvantage is that disassembly, assembly, and maintenance are relatively complicated. Usually used when the magnetic drive pump motor power is small.

Indirect coupling structure is also called bearing bracket structure. The external magnetic rotor is driven by the drive shaft to actively rotate, and the drive shaft and the magnetic drive pump motor shaft are connected by a coupling. The advantage is that disassembly, assembly, and maintenance are very simple and convenient, and the operation is smooth. The disadvantage is that the axial dimension is long and the space volume is large. Mainly used in situations where the motor power is relatively large.

According to the Cooling Cycle Method

The internal circulation method is mainly used for the transportation of normal temperature and pure media. Its main feature is that the cooling circulation path is completed within the magnetic drive pump. The external circulation method is mainly used for conveying high-temperature and granular media. Its main feature is that the cooling circulation path passes outside the magnetic drive pump and then returns to the magnetic drive pump to form a circulation path. Magnetic drive pump structure is relatively complicated, and its disassembly, assembly, and maintenance are also relatively complicated.

Application

- Chemical Industry: Magnetic drive pumps are often used to transport corrosive, toxic, or volatile chemicals such as acids, alkalis, solvents, and media in chemical reactions. Since there is no mechanical seal in the pump, leakage can be prevented and production safety ensured.

- Pharmaceutical Industry: In pharmaceutical processes where precise delivery of pharmaceuticals, solvents, and other chemicals is required, the non-contact nature and high-precision measurement of magnetic drive pumps make them ideal.

- Water Treatment: Used to treat wastewater, water supply systems, and sewage treatment plants, capable of handling the transportation needs of different liquids while preventing cross-contamination.

- Semiconductor Production: In semiconductor manufacturing, a high-purity chemical reagent supply is required to ensure the quality of semiconductor production. Magnetic drive pumps provide highly pure and controlled chemical delivery.

- Laboratory Applications: In scientific research laboratories, precise liquid transport is required for chemical experiments and sample analysis. Magnetic drive pumps can be used to meet the precise requirements of experiments.

- Medical Devices: Used for fluid delivery in medical devices such as blood analyzers, dialysis machines, and drug delivery equipment.

- Food and Beverage Industry: In food and beverage production, magnetic drive pumps are used to transport food, beverages, additives, and raw materials, ensuring hygiene and traceability of the production process.

- Energy Industry: Used to transport petroleum, chemical products, and natural gas to meet energy needs.

- Environmental Monitoring: In environmental monitoring applications, magnetic drive pumps are used to collect water, chemical, and gas samples for environmental research and monitoring.

Magnetic drive pumps are highly efficient pumps for the handling of corrosive, toxic or expensive liquids, with a unique magnetic coupling principle that eliminates mechanical seals, thereby improving operational safety, reliability and control of liquid leakage. This makes the magnetic drive pump very useful in a range of industrial and laboratory applications. ATO store can provide you with high-performance magnetic drive pumps, many types of magnetic drive pumps are ideal for you to handle corrosive, toxic, or expensive liquids, not only reliable, and efficient, but also provide excellent liquid leakage control, if you are interested, welcome to click.