What is the Procedure of Steam Autoclave Sterilizer?

In the medical, laboratory and industrial fields, maintaining a sterile environment is critical to preventing the spread of microorganisms and ensuring the accuracy of experimental results. As a commonly used sterilization equipment, steam autoclave provides us with a reliable and efficient sterilization solution. This article will introduce the general operation process of the steam autoclave to help you operate the equipment correctly to ensure effective sterilization and the establishment of a sterile working environment.

Operating procedures

Step 1: Open the lid and add water

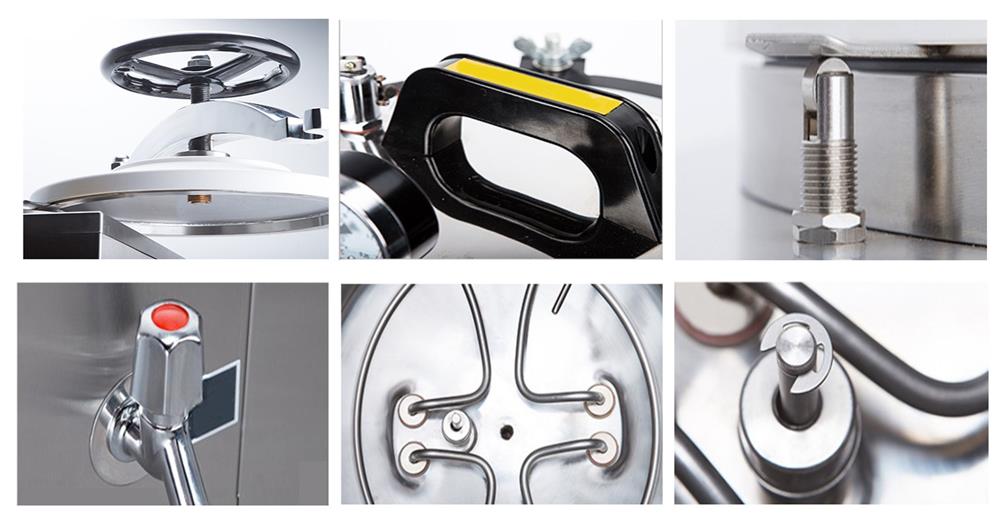

First, make sure the power to the steam autoclave sterilizer is turned off. Then, carefully open the lid of the sterilizer and confirm that there are no items inside. For a portable autoclave, use a rotating quick-open structure, and the lid can be opened by rotating it. For vertical autoclaves steam autoclaves, you need to turn the handwheel counterclockwise until it cannot be turned, so that the sterilizer cover can be fully lifted, and the sterilizer cover can be removed by pushing the beam to the left. Next, using a clean container or water filling device, add the appropriate amount of purified water to the autoclave's sink. Depending on equipment requirements, distilled or deionized water can be used. However, make sure that the water level does not exceed the maximum mark line specified by the equipment, so as to avoid poor sterilization effect or equipment damage due to excessive water level.

Step 2: Putting items in and sealing

Place the items to be sterilized inside the steam autoclave. Arrange items according to their size and shape, making sure there is enough space between them for adequate steam circulation. Take care to avoid items touching or overlapping each other. For sensitive items or liquid samples, use appropriate containers or sealed bags for packaging to prevent contamination or leakage during sterilization. When you are finished placing items, carefully close the door or lid of the autoclave and make sure it is completely sealed.

Step 3: Set the sterilization parameters and start the sterilization program

According to the nature of the item and the sterilization requirements, carefully set the appropriate sterilization parameters. Set the desired temperature, pressure and sterilization time using the relevant buttons or knobs on the device control panel. Make sure the parameters are set correctly and adjust as needed. After confirming that the parameter setting is completed, press the start button to start the sterilization process. The device will start heating and increasing the pressure, and automatically adjust the temperature and pressure to achieve the set parameters. During start-up, the device may display relevant messages or light up to indicate that the sterilization process is in progress.

Step 4: Sterilization continues

Once the autoclave reaches the set temperature and pressure, start the timer to maintain the set sterilization time. During this period, the equipment will continue to maintain the set temperature and pressure to ensure that the items are fully sterilized. Monitor the device's display or indicator lights to ensure parameters remain stable and make adjustments as needed. During the duration of the sterilization process, the device may emit an audible or light signal to indicate that the sterilization process is in progress.

Step 5: Cool and pressure release

After the sterilization time has elapsed, the autoclave automatically stops heating. At this point, the device enters a cooling phase, reducing temperature and pressure. During cooling, the device may display remaining cooling time or temperature changes. After the internal temperature of the equipment has dropped to a safe range, follow the equipment's operating instructions and carefully open the exhaust valve or other safety device to release residual steam and pressure. Be sure to use caution during release to avoid burns or injury.

Step 6: Open the sterilizer and remove items

Carefully open the door or lid of the autoclave after confirming that the pressure inside the device is completely relieved. At this point, hot steam may be released, so be cautious. Carefully remove sterilized items using appropriate tools, such as long gloves and tongs. Caution Items may still be hot, handle with care to avoid burns.

Step 7: Cleanup and maintenance

After the sterilization process is complete, it is critical to perform equipment cleaning and maintenance. Clean the interior and exterior surfaces of the equipment, including sinks, seals, exhaust valves, etc., using appropriate cleaners and tools according to the equipment manufacturer's recommendations. Regularly inspect and replace worn parts such as seal rings and filters. Make sure the device is kept dry and clean to prolong its life and maintain its performance.

Some common repair and maintenance suggestions

Regular cleaning: Regular cleaning of your steam autoclave is an important step in keeping it functioning properly. To use proper cleaning agents and tools, clean internal and external surfaces, including sinks, sealing rings, steam lines, etc., taking care not to damage or wear equipment during cleaning.

Check and replace seals: Regular inspection and replacement of seals is key to preventing steam leaks. Components such as sealing rings and door rubber rings may wear or age over time, resulting in a decrease in the sealing performance of the sterilizer. Periodically inspect these parts for wear and replace as necessary.

Check and clean filters: Steam autoclaves are usually equipped with filters to filter out impurities from the steam. Check and clean the filter regularly to make sure it is unobstructed and replace the filter if necessary.

Inspect and maintain vent valves and safety devices: Vent valves and other safety devices are an important part of ensuring safe operation of the sterilizer. Regularly check the function of the exhaust valve and safety devices and make sure they are working properly. Clean, lubricate or replace as needed.

Calibrate and adjust temperature and pressure control: Temperature and pressure control are critical to the proper operation of a steam autoclave. Regularly calibrate and adjust temperature and pressure controllers to ensure their accuracy and stability.

Regular service and maintenance: Regular service and maintenance is key to ensuring the long-term operation of your steam autoclave. Perform regular repairs and maintenance as recommended by the equipment manufacturer, including replacing worn parts, lubricating moving parts, checking electrical systems, and more.

Entrust professional maintenance: For larger failures or situations that require professional maintenance, it is recommended to entrust professional technicians for maintenance. Contact the equipment manufacturer or authorized maintenance service provider for professional technical support and service.