Y-type Strainer Installation & Maintenance

Sat, Apr 29 by ATO.com

The Y-type strainer is a small device that removes a small amount of solid particles in the liquid, which can protect the normal operation of the device. When the fluid enters the filter cartridge with a certain size filter, its impurities are blocked, and the clean filtrate is discharged from the outlet of the Y-shaped strainer. When cleaning is required, just take out the detachable strainer cartridge and reinstall it after treatment. Therefore, it is extremely important to install and maintain the Y-type strainer correctly. Let me provide you the knowledge about the installation and maintenance of the Y-type strainer.

Y type strainer installation direction

When the Y-type strainer is used for steam, gas and liquid, the installation direction is slightly different:

- Steam or gas pipeline: install the filter screen in a horizontal direction.

- Liquid pipeline: install the filter screen downward.

- Vertical installation: according to the installation orientation of the filter.

Y-type strainer installation and maintenance

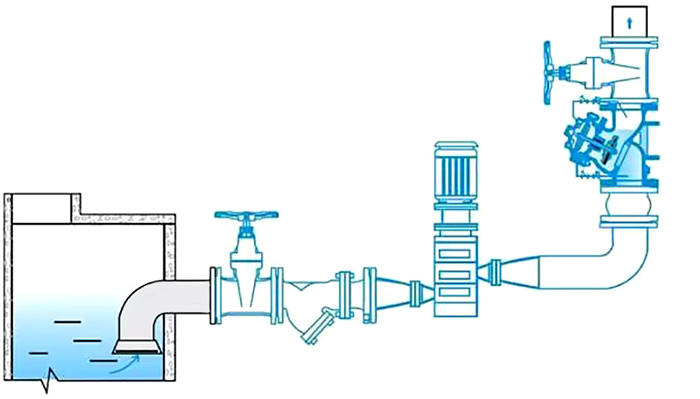

- The installation of the Y-type strainer should be carried out according to the flow direction, recommended installation method and installation requirements shown in the product catalog and installation instructions provided by the manufacturer. The upstream and downstream of the Y-type strainer can be equipped with differential pressure gauges according to the needs of process production to judge the clogging situation, and the back flushing cleaning pipeline should be configured according to the process needs.

- When piping, the convenience of installing and removing the Y-type strainer should be considered. Pipeline Y-type strainer has requirements for pipeline design.

- Pipelines equipped with Y-type strainers can be divided into intermittent operation and continuous operation. During discontinuous operation, set shut-off valves before and after the Y-type strainer to clean the Y-type strainer. For continuous operation, two sets of Y-type strainers in parallel should be installed for the Y-type strainer, and cut-off valves should be set before and after the Y-type strainer.

- The Y-type strainer should be installed at the inlet of the pipeline in order to filter out impurities and particles. At the same time, you should choose a location that is easy to maintain and clean. The Y-type strainer requires a mounting bracket to ensure its stability and safety. The bracket should be made of strong material and firmly connected with the pipeline. The Y-type strainer needs to be connected to the pipeline, and the diameter and connection method of the pipeline should be paid attention to when connecting to ensure a firm connection. Valves should be installed at the inlet and outlet of the Y-type strainer for easy maintenance and cleaning.

- A pressure gauge should be installed at the inlet of the Y-type strainer to monitor the working condition of the filter. The Y-type strainer needs to be cleaned regularly to ensure its filtering effect. When cleaning, the inlet and outlet valves should be closed, the filter should be removed, and the filter screen and internal impurities should be cleaned.

- The filter screen is the core component of the Y-type strainer and needs to be replaced regularly. When replacing, you should choose the filter screen of the same model and specification as the original one. The tightness of the Y-type strainer is very important to its filtering effect and safety. It is necessary to check the tightness regularly, and replace the seals in time if there is any problem. The valves at the inlet and outlet of the Y-type strainer also need to be checked regularly, and replaced in time if there is any problem.

- After the Y-type strainer works for a period of time, certain impurities will be deposited in the filter element, the pressure will increase, and the flow rate will decrease. It is necessary to remove the impurities inside the filter element in time. When cleaning is required, unscrew the screw plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and reinstall it after cleaning. Note that the stainless steel wire mesh on the filter element cannot be deformed or damaged. Otherwise, the filtering effect of the reinstalled filter will not meet the design requirements. If the stainless steel wire mesh is found to be deformed or damaged during inspection, it should be disassembled and replaced immediately. The pressure gauge at the inlet of the Y-type strainer needs to be checked regularly, and replaced in time if there is any problem.

- When installing a large-diameter socket welding Y-type strainer, pay attention to whether this type of Y-type strainer gasket is made of non-metallic material. If it is made of non-metallic material, it is easy to cause damage due to overheating, so after welding is completed, the Y-type strainer should be cooled quickly to reduce the welding time.

Y-type filter maintenance

- The water flow direction of the y-type strainer system should be consistent with the direction of the arrow on the valve, either horizontally or vertically. If water leakage occurs, it may be that the gasket is damaged and can be replaced.

- Check regularly whether there are too many impurities in the Y-type strainer. This method can be used: install pressure gauges at both ends of the Y-type strainer system. When the pressure readings at both ends of the Y-type strainer system differ greatly, it indicates that there are a lot of impurities in the filter screen and can be cleaned.

- When maintaining the Y-type strainer, also pay attention to cleaning the filter frequently, because the filter is easy to breed bacteria and pollute the liquid in the pipeline. I would like to remind everyone that in order to protect the equipment from working normally for a long time, during daily use and maintenance, it is necessary to protect the fittings on the equipment pipeline to avoid wear and blockage.

Function of Y-type filter

- Y-type strainer is an indispensable filter device for the pipeline system of conveying medium. It has the advantages of simple manufacture, advanced structure, convenient installation and cleaning, large pollutant holding capacity, small resistance and convenient sewage discharge.

- Y-type strainer is usually installed at the inlet of pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to remove impurities in the medium to protect the normal use of valves and equipment. The applicable medium can be water, oil, gas.

- Y-type strainer is divided into flange connection, threaded connection and welded connection, and the process is divided into casting and welding. The specific conditions are verified according to the actual working conditions and technical requirements, and the customer needs to provide.