Check Valve Selection Guide

Check valves, also known as one-way valves, are designed to prevent the backflow of media in the pipeline. The bottom valve for water pump suction and closing also belongs to the check valve category. A valve that relies on the flow and force of media to open or close itself to prevent media backflow is called a check valve. It belongs to the category of automatic valves and is mainly used in pipelines with unidirectional flow of media. It only allows media to flow in one direction to prevent accidents.

Factors for Your Option

- Application of the Check Valve

Generally suitable for cleaning media, not suitable for media containing solid particles and high viscosity. - Nominal Diameter of the Check Valve

For low-pressure check valves below DN50mm, butterfly check valves, vertical lift check valves, and diaphragm check valves should be selected; For medium and low pressure check valves with a DN greater than 200mm and less than 1200mm, it is recommended to choose a wear-free ball check valve. For low pressure check valves with a DN greater than 50mm and less than 2000mm, butterfly check valves and diaphragm check valves should be selected.

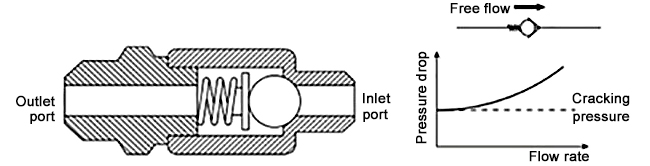

- Flow Characteristics

If a check valve closes very quickly, it may prevent slamming against upstream equipment such as pumps. However, fast closing does not prevent surges caused by pump start-up and shutdown. If the valve opens (and closes) quickly, the flow rate will change rapidly thereby increasing the likelihood of surging. - Head Loss of the Check Valve

The head loss is one of the functions of fluid velocity. The head loss of a valve is determined by its internal design and opening. When the valve is designed with a restricted (narrowed) opening compared to the pipeline, the speed through the valve will increase, thereby increasing pressure head loss. Conversely, if the design limitations of the valve are small and the aperture is the same as the pipe size, the head loss will be smaller, and the valve will not actually affect the overall head loss of the system. There are many values for head loss, including zeta value, Kv, and Kvs value. - Total Cost of Ownership

The cost of a check valve is not just the purchase price. For some installations, the most important costs may be procurement and installation, but in other cases, maintenance or energy costs may be equally or even more important. It is also necessary to consider protecting more valuable equipment, such as pumps, and checking valve performance will be crucial. When using cost as the selection criteria for check valves, the total cost of the check valve throughout its service life should be considered. Generally speaking, the simpler the valve structure, the lower the maintenance requirements. The higher the Kv value, the lower the energy consumption. The higher the performance, the better the protection ability.

Tips for the Check Valve Selection

- The straight lift check valve can only be installed in horizontal pipelines;

- For the pump inlet pipeline, a bottom valve should be selected. The bottom valve is generally only installed on the vertical pipeline at the pump inlet, and the medium flows from bottom to top;

- The lifting type has better sealing performance and greater fluid resistance than the rotating type, so it should be installed horizontally in horizontal pipelines and vertically in vertical pipelines;

- The installation position of swing check valves is not restricted. Can be installed on horizontal, vertical, or inclined pipelines. If installed on a vertical pipeline, the flow direction of the medium should be from bottom to top.

ATO stores offer a variety of check valves for you to choose, such as swing check valves, wafer check valves, ball check valves, foot valves etc.. In order to choose a suitable check valve in a right way, several selection criteria should be considered. However, no type of check valve is the best choice for all applications, and the selection criteria may not be equally applicable for all situations. You need to consider the following items: applicability of check valves, nominal diameter of check valves, flow characteristics, head loss, non impact characteristics, and total cost of ownership.