What is Knife Gate Valve used for?

A knife gate valve is a valve used to shut off or regulate fluid. It is usually installed on the pipeline to control the flow of the inlet and outlet by raising or lowering the valve plate. Nowadays, knife gate valves are widely used in industry and bring great value to people's industrial production. How much do you know about the specific application range of knife gate valves? If you are interested in the application of knife gate valves, we will provide you with more application knowledge.

Where does the knife gate valve do?

Knife gate valve, as the name implies, is a valve with a knife-shaped cutout on the bottom of the valve plate, which has the function of cutting off the medium, so that the valve is closed without being blocked by the medium. This valve is generally used for opening and closing the circulation of pulp, coal ash, chemical raw materials, sewage, food, and other media. The pressure range is generally used within 1.6MPa, and the temperature is generally used below 120°C. The valve has obvious advantages such as a light switch, reliable sealing, good elastic memory, and long service life.

The uses of knife gate valves include the following aspects.

Used for shutting off liquid, gas, and steam: As a common pipeline gate valve, a knife gate valve can be used to shut off various fluids, including liquid, gas, steam, etc.

Used for shutting off powdery and granular media: the knife gate valve has a simple structure and is not easy to accumulate debris inside, so it is also suitable for powdery and granular media.

Interception of shape and granular media.

For flow control: Since the valve plate can be raised or lowered to adjust the flow, the knife gate valve can also be used for flow control system applications.

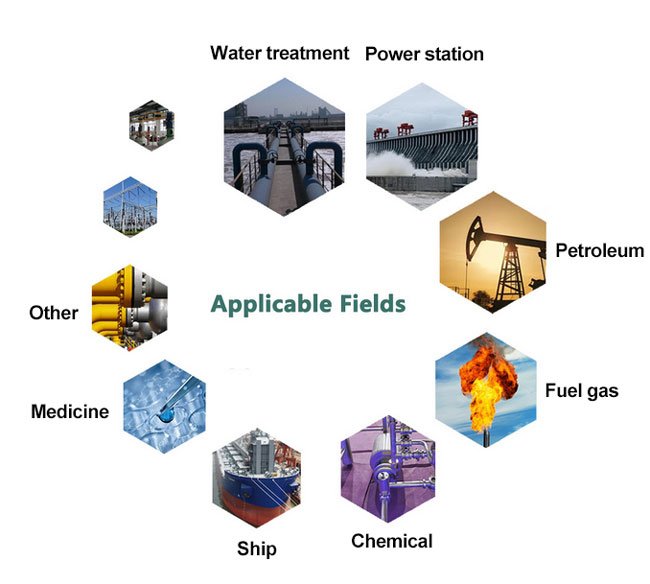

For the control of high temperature and high-pressure fluid: Knife gate valve has an excellent performance in the power of high temperature and high-pressure fluid, and can operate stably in high temperature and high-pressure environment, so it is widely used in the chemical industry, electric power, oil and natural gas and other industries.

The function of the knife gate valve

Cut off medium flow

The knife gate valve is suitable for the opening and closing control of the medium flow in the pipeline, which can realize the cutting and opening of the medium, and has the advantages of fast and easy operation.

Control media flow

The opening size of the knife gate valve can affect the flow rate, and the flow rate of the medium in the pipeline can be controlled by adjusting the opening size.

Prevent media backflow

The special structure of the knife gate valve can effectively prevent the medium from flowing backward along the pipeline, so as to ensure the normal transportation of the medium and avoid damage to the system.

Guarantee media quality

In pipelines, if the different media in the pipeline carry harmful substances, it will cause damage to the production. The knife gate valve can effectively control the flow of the medium and ensure the quality of the medium, thereby avoiding adverse effects on the production process.

Control pressure

In the process of industrial production, it is often necessary to control the flow direction of the medium by adjusting the pressure in the pipeline. The knife gate valve can act as a pressure control valve in the pipeline to achieve rapid control of the medium pressure.

Knife gate valve applications and suitable media

- Power station ash removal - suitable for mortar.

- Purification device - suitable for waste water, mud, dirt, and clarified water containing suspended solids.

- Paper industry - suitable for any concentration of pulp and water mixture.

- Mining, coal washing, iron and steel industry - suitable for coal washing pipelines, filter residue pipelines, etc., and ash discharge pipelines.

Difference between knife gate valve and normal gate valve

The difference between the knife gate valve and the ordinary gate valve is that the structure is simple, the opening and closing mechanism is a gate, and the movement direction of the gate is perpendicular to the direction of the fluid. Small size, flexible operation, easy assembly, more suitable for medium with high consistency and solid particles.

As can be seen from the name, the key of the knife gate valve is to use the knife gate to cut off the medium. The gate has two sealing surfaces that form a wedge. The gate can be made into a one-piece rigid gate, or it can be made into an elastic gate, which can cause slight deformation to improve the sealing ability technically. Generally speaking, compared with ordinary gate valves, knife gate valves mainly highlight some advantages of the following products:

- The sealing effect of the U-shaped gasket is remarkable.

- Full-bore design, so that the medium can pass through. And it is easy to assemble, disassemble and maintain when the medium is dirty, making the maintenance of the valve easier.

- The gate with the function of the gate knife has a remarkable breaking effect, which can effectively cut off some sundries in the medium, and deal with the leakage of the medium containing lumps, particles, and fibers after breaking the gate.

- The structure length of the knife gate valve is ultra-short, the volume is small, the flow resistance is small, the weight is light, the material is reasonably saved, and the effective space is small.

Structure

The knife gate valve mainly includes three parts, which are the control hand wheel of the knife gate valve, the outer wall of the valve, and the internal control device. We use the knife gate valve mainly by manipulating the easy-to-operate hand wheel on the knife gate valve to make the control device inside the valve body perform a series of physical movements, and finally form the opening and closing of the valve, so that the knife gate valve can work normally.

The internal structure of the knife gate valve is very complicated. We turn the hand wheel of the knife gate valve by hand to make it rotate, so that the knife gate valve can affect the internal levers and gears to work. After the linkage movement, the blocking device inside the valve changes rapidly, and the knife gate valve is opened and closed according to the different rotation directions. Moreover, such work can be completed in a very short time, which can effectively save time and improve work efficiency.

In short, the knife gate valve plays an important role in industrial production. It can not only realize the cutting, opening, and flow control of the medium but also prevent the backflow of the medium and ensure the quality of the medium. It can also act as a pressure control valve to realize the rapid adjustment of the medium pressure control. In order to ensure the normal function of the knife gate valve, careful maintenance is required during use to avoid rust, oxidation, and other phenomena, and to develop good usage habits, so that the application of the knife gate valve can play a better role.