Contactors

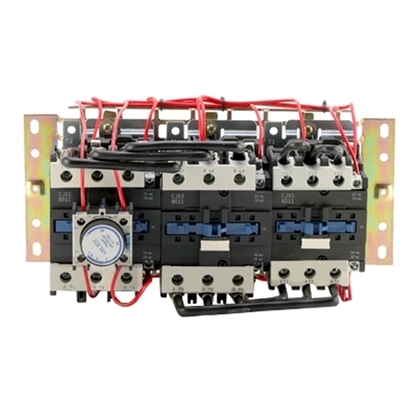

95A Star Delta Starter, 45kW/ 80kW, 220V/ 380V AC

1000A High Voltage DC Contactor, 9-36V Coil Voltage

150A DC Contactor, 12V/24V/48V

250A DC Contactor, 12V/24V/48V

9 amp Mechanical Interlock AC Contactor

12 amp Mechanical Interlock AC Contactor

1200A High Voltage DC Contactor, 9-36V Coil Voltage

18 amp Mechanical Interlock AC Contactor

25 amp Mechanical Interlock AC Contactor

32 amp Mechanical Interlock AC Contactor

40 amp Mechanical Interlock AC Contactor

50 amp Mechanical Interlock AC Contactor

65 amp Mechanical Interlock AC Contactor

80 amp Mechanical Interlock AC Contactor

95 amp Mechanical Interlock AC Contactor

10A/20A/40A/60A/100A/150A 3 Pole AC Contactor, 24V/110V/220V/380V Coil

115 amp 3 phase AC Magnetic Contactor, 24V/110V/220V Coil

150 amp 3 phase AC Magnetic Contactor, 24V/110V/220V Coil

185 amp 3 phase AC Magnetic Contactor, 24V/110V/220V Coil

225 amp 3 phase AC Magnetic Contactor, 24V/110V/220V Coil

A contactor is an automatic electromagnetic switch that closes and disconnects the current through the contacts through electromagnetic force. In addition, the magnetic contactor also has a low pressure release function, which is suitable for frequent operation and running distance control.

In electrical engineering, because the contactor is a device that can quickly cut off the AC and DC main circuits and can frequently turn on and off high-current control (up to 800A) circuits, it is often used in motors as control objects, and it can also be used as a control object. The electrical contactor is used to control electrical loads such as factory equipment, electric heaters, working mother machines and various power units. The contactor has a large control capacity, which is suitable for frequent operation and long-distance control, and is one of the important components in the automatic control system.

Contactors are divided into AC contactors (voltage AC) and DC contactors (voltage DC). As a high-power switching device, it is widely used in aerospace, aviation, weapons, ships, electronics and other system equipment. The control load current is greater than 25A, and the voltage is 25VDC; 115VAC, 402Hz; 386VAC, 50Hz. The power distribution switch controls the power supply or controls the start-stop control of high-power motors. It is a key device in the equipment and plays an important role.

How does the contactor work?

The magnetic contactor is mainly composed of electromagnetic mechanism, contact system and arc extinguishing device. The electromagnetic mechanism is a sensing element, and when it senses a certain electrical signal, it will drive the contacts to close or break. It mainly includes coil, iron core and armature.

When the contactor coil is energized, the coil current will generate a magnetic field, and the generated magnetic field will make the static iron core generate electromagnetic attraction to attract the moving iron core, and drive the AC contactor point to move, the normally closed contact is disconnected, the normally open contact is closed, and the two are linked. When the coil is powered off, the electromagnetic attraction disappears, and the armature is released under the action of the release spring, so that the contacts are restored, the normally open contacts are disconnected, and the normally closed contacts are closed. The working principle of a DC contactor is somewhat similar to that of a temperature switch.

5 types of contactors on ATO.com

DC contactor

DC contactor refers to a contactor whose iron core is DC control, and its load can be either DC or AC. The iron core of the DC contactor is different from the AC contactor. It has no eddy current, so it is generally made of mild steel or industrial pure iron into a round shape. Since the attracting coil of the DC contactor is connected to DC, there is no impact starting current, and there is no violent impact of the iron core, so it has a long service life and is suitable for frequent starting and stopping.

AC contactor

AC contactors often use three types of arc extinguishing methods: double-break electric arc extinguishing, longitudinal seam arc extinguishing and grid arc extinguishing. It is used to eliminate the arc generated by the moving and static contacts during the opening and closing process. Contactors with a capacity of more than 10A have arc extinguishing devices. The AC contactor also has auxiliary components such as reaction spring, buffer spring, contact pressure spring, transmission mechanism, base and terminal.

Vacuum contactor

The vacuum contactor uses a vacuum interrupter to extinguish arcs to frequently connect and cut off the normal working current. It is usually used to remotely connect and disconnect medium and low voltage 6kV, 380V (660V, 1140V) with frequent start and stop. ) AC motor.

Lighting contactor

The lighting contactor is a relay switch, providing reliable and convenient lighting control. Magnetic contactors operate at lower but safer loads and optimize the electromagnetic system to reduce maintenance power.

Definite purpose contactors

ATO has dedicated contactors designed for the heating, ventilation, air conditioning and refrigeration industries.

What are the main parts of a contactor?

Taking AC contactor as an example, it consists of electromagnetic mechanism, contact system, arc extinguishing system, reaction force device, bracket and base.

1. Electromagnetic mechanism

The composition of the electromagnetic mechanism: It is composed of electromagnetic coil, iron core and armature.

The function of the electromagnetic mechanism: the closing and opening of the operating contacts.

2. Contact system

The magnetic contact is the first opening element of the contactor, which is used to make or break the controlled circuit. The contact system includes main contacts and auxiliary contacts.

- Main contact: Used in the main circuit with large on-off current.

- Auxiliary contact: Used to connect or disconnect the control circuit, only a small current can be passed.

3. Arc extinguishing system

Contactors with a capacity of more than 10A have arc extinguishing devices, often using longitudinal slit arc extinguishing covers and grid arc extinguishing devices.

4. Reaction device

Including spring, transmission mechanism, terminal and shell, etc.

5. Brackets and bases

For fixing and installation of contactors.

Difference between AC contactor and DC contactor

- The main difference between AC contactor and DC contactor is in the iron core and coil. There are eddy currents in the electromagnet core of the AC contactor, so the electromagnet cores are made into pieces and stacked together. The electromagnet core of the current contactor is an integral iron core, the coil is slender and the number of turns is particularly large.

- The main circuit of the DC contactor is generally two poles, and the DC only has positive and negative poles. The AC contactor has three poles because of the opening and closing of three-phase electricity.

- For the AC circuit, when the contactor is disconnected, the overvoltage generated by the circuit is small. At the same time, when the AC arc has a zero-crossing time, the arc will be extinguished and reignited after the zero-crossing, so the AC arc measures are relatively easy. For the DC circuit, when the contactor is disconnected, the overvoltage generated by the circuit is too high, and the arc is not easy to extinguish. It can be seen that compared with the AC contactor, the DC arc extinguishing measures are relatively difficult.

- The protection coordination relationship (SCPD) of DC and AC is different, and the parameter table must be carefully consulted when using.

Why use contactors to control motors?

When the motor starts, its starting current is very large. Generally, the starting current of the motor should be 5-7 times, and the starting current of the small-capacity motor is larger. When the motor is disconnected, since the motor is an inductive load, a relatively high voltage will be induced at both ends of the switch contacts at the moment of disconnection, thereby breaking down the air gap between the contacts and forming an arc. Therefore, the electrical appliance that controls the breaking motor must have the ability to withstand the impact of the starting current and extinguish the arc when it is disconnected. Therefore, an electrical appliance with the above-mentioned capabilities, such as a contactor or an air switch, is chosen to control the breaking motor.

The control relay node does not have the above functions, so use the relay node to start the contactor, and use the contactor node to control the motor. In places with a high degree of automation, the contactor is used as the final actuator for the start and stop of the motor due to its low price and reliability. Large motors above 4200KW are also controlled by air switches. This is often used in large industrial enterprises, because at this capacity class, the contactor is not sufficient. The most important thing is that the contactor can meet the closing-opening operation of 300,000 times, and can meet the component life requirements of frequent starting and stopping electrical circuits.

Filter by:

Clear All