Different Types of Contactors

Contactors are used in electric power, distribution and electricity applications. A contactor refers to an electrical appliance that uses a coil to flow through a current to generate a magnetic field to close the contacts in order to control the load in industrial electricity. There are many types of contactors according to their purpose and characteristics.

Types of Contactors

According to the voltage of the control coil, it can be divided into DC contactor and AC contactor. Electromagnetic contactors, hydraulic contactors and pneumatic contactors are divided depending on the operation structure. According to the action mode, it can be divided into direct-acting contactor and rotary contactor. For the number of poles of the main contacts (the number of main contacts), there are two types of DC contactors: single pole and double pole. AC contactors have three poles, four poles and five poles.

AC contactors and DC contactors are the most common contactors. AC contactors often use three arc extinguishing methods: double-break electric arc extinguishing, longitudinal seam arc extinguishing and grid arc extinguishing to eliminate arcs generated during the opening and closing process of moving and static contact. ATO low price lighting contactors and definite purpose contactors are AC contactors that can control systems well.

DC contactor refers to a contactor whose iron core is DC control, and its load can be either DC or AC. Unlike the AC contactor, its iron core has no eddy current, so it is generally made of mild steel or industrial pure iron into a round shape. DC contactors are suitable for occasions with frequent start and stop. For occasions with frequent start and stop, DC contactors with superior performance are very suitable.

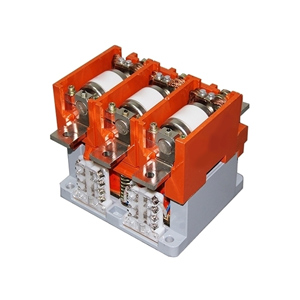

A semiconductor contactor is a kind of current operation by changing the on-state and off-state of the semiconductor circuit loop. A permanent magnet contactor is a micro-power contactor formed by replacing the traditional electromagnet drive mechanism with a permanent magnet drive mechanism using the principle of the same-sex repulsion and opposite-sex attraction of magnetic poles. There are also some other types of contactors. In order to extinguish the arc, the vacuum contactor is a type of contactor whose contact system adopts a vacuum degaussing chamber.

When the AC contactor coil is energized, a magnetic flux is generated in the iron core. As a result, a suction force is generated at the air gap of the armature, which causes the armature to produce a closing action. The main contact is also closed under the drive of the armature, and the main circuit is connected. At the same time, the armature also drives the action of the auxiliary contacts to close the originally opened auxiliary contacts, so that the originally closed auxiliary contacts are opened. When the coil is powered off or the voltage is significantly reduced, the suction force disappears or weakens, the armature opens under the action of the released spring, and the main and auxiliary contacts return to their original states. This is how a contactor works. The main purpose of the contactor is to control the starting, reversing, speed regulation and braking of the motor. It is the most important and most commonly used control electrical appliance in the electric drag control system.