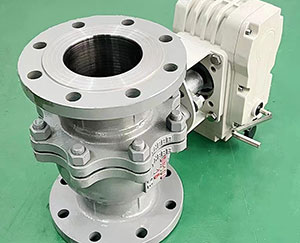

Electric Ball Valve Selection Guide

Electric ball valves are a common type of industrial valve, widely used in various fluid control systems. However, there are many factors to consider when selecting the right electric ball valve. In this article, ATO Store will discuss the selection process of electric ball valves in detail, including information on the working environment, valve material, caliber specification, control mode, actuator parameters and brand selection.

Fluid Medium and Working Environment:

In the selection of electric ball valves before you first need to understand the fluid medium you are dealing with and the working environment. Different media may have different material requirements, and some media may be corrosive to the valve body and sealing materials. In addition, the working environment of the temperature, pressure and humidity and other factors also need to be considered to ensure that the selected motorized ball valve can adapt to your working conditions, so that its safe and reliable operation. For example, will the ball valve be used indoors or outdoors? Is the ambient temperature high or low? Is there corrosive media present? All of these factors will have a direct impact on the material selection and mechanical performance requirements of the motorized ball valve.

Valve Materials and Sealing Performance:

According to the different environments of use, the choice of materials for electric ball valves will also be different, and the material of the valve body of electric ball valves directly affects its corrosion resistance and sealing performance. Common materials include stainless steel, carbon steel, cast iron, etc., of which stainless steel is one of the most commonly used materials, with excellent corrosion resistance. In addition, it is also necessary to consider the choice of sealing materials, such as PTFE, polytetrafluoroethylene, etc., so as to ensure that the valve can be effectively sealed.

Caliber Specification:

The caliber specification of the electric ball valve should be determined according to the needs of the fluid system. Too large or too small will affect the flow control effect of the valve. Therefore, in the selection should be based on the flow of fluid media, flow rate and system requirements to choose the appropriate caliber specifications. It is also necessary to confirm the connection between the pipe diameter and the valve, such as: flange, thread, clamp, etc..

Control Mode and Function:

Electric ball valves have many control methods to choose from, such as manual, electric and pneumatic control. Choose the suitable control method according to your needs and the degree of automation. In addition, some electric ball valves have additional functions, such as position feedback, alarm function and remote control. Consider these functions according to actual needs to improve the flexibility and operability of your system.

Actuator Parameter:

You need to confirm the voltage size and power requirements, or according to the media pressure, pipe size to select the corresponding actuator model, different size pressure requires different opening torque, but also pay attention to whether the actuator with manual switch and other detailed requirements.

Brand Selection:

Consider choosing a reliable brand when shopping for electric ball valves. Well-known brands usually have better quality assurance and after-sales service, which can ensure stable performance and long-term reliable operation of the valve. In addition, brand selection can also be considered from the brand's reputation, user reviews and market share .

.

In short, the selection of suitable electric ball valves needs to take into account the working environment, valve materials, caliber specifications, mode of operation and brand selection and other factors. Only in a full understanding of the application requirements based on a comprehensive comparison and evaluation, in order to select the most suitable electric ball valve. Through proper selection, we can ensure the efficient operation and reliability of the valve in industrial fluid control