Gloss Meter Basics

Working principle

Gloss is a physical quantity that evaluates the ability of a material surface to reflect light under a set of geometrically specified conditions, with directional selective reflection properties. The gloss we usually say refers to mirror gloss, so the gloss meter is sometimes called mirror gloss meter. Gloss is quite different from the machining industry's concept of finish or roughness, which is a continuation of the tiny unevenness on a material's surface.

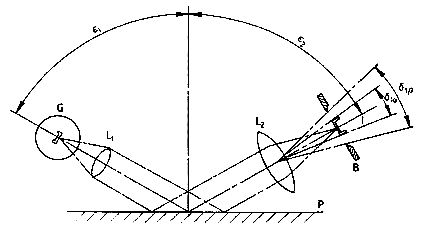

The measurement principle of the gloss meter is shown in the figure below. The measuring head of the instrument is composed of a transmitter and a receiver. The transmitter is composed of an incandescent light source and a group of lenses, which generate a certain required incident beam. The receiver consists of a lens and a photosensitive element for receiving the cone beam reflected from the sample surface.

Mirror gloss is a relative measure of mirror gloss. The reference standard is black glass with a refractive index of np=1.567. Assuming that its plane is in an ideally polished state, the natural light beam will be mirror-reflected by the plane, and the gloss value at this time is defined as 100.0 gloss units. Gloss board is divided into high, medium and low according to the gloss value. High gloss plates are made of black optical glass or other materials. Medium and low gloss panels are made of glazed ceramic or black optical glass frosted. Gloss meters use the principle of light reflection to measure the gloss of a sample. That is, the sample is irradiated under the conditions of a predetermined incident angle and a predetermined light beam, and the reflected light in the direction of the mirror reflection angle is obtained.

Many optical properties of materials can be qualitatively explained by wave theory. According to the wave theory, it can be derived that the ratio of the energy W of the incident light passing through the unit area per unit time to the energy flow W of the reflected light per unit time.

Measurement

- From a place with a lower temperature to a place with a higher temperature (such as outdoor to indoor in winter), please wait for a while before measuring. (Because the surface of the optical lens will be fogged from a place with low temperature to a place with high temperature) Please do not measure in the environment where the sunlight directly shines on the measured object, so as not to affect the measured value.

- When using the small hole gloss meter to measure the curved object, in order to ensure that the small hole is completely covered by the medicine, when the amount is consumed, the measuring hole of the gloss meter can be slowly covered along the tangent of the measured curved surface until the object to be measured cannot be seen. The light spot on the object to be measured (the white light spot illuminated by the measuring hole on the object to be measured) is sufficient.

How to use

Press the switch, the instrument is placed on the black glass standard plate, and the adjustment knob is rotated to make the displayed value the same as the nominal value of the standard plate. Then the instrument is placed on the white ceramic standard plate, and the error between the displayed value and the nominal value of the white ceramic standard plate should not be greater than ±1.2 gloss units, otherwise problems such as contamination of the standard plate should be considered. This process does not need to be done every time. When the error is out of tolerance, re-calibrate according to the above method. After calibration, the sample can be measured. Overflow 1 is displayed when the measurement exceeds 199.9 gloss units.

Note: The gloss meter uses one AA alkaline battery. After opening the battery cover, install the battery according to the positive and negative signs. Please do not install it in reverse. When the under-power sign "←" is displayed, the battery should be replaced in time.

Application

The gloss meter is suitable for the measurement of mirror gloss of coatings, paints, inks, plastics, stone, floors, wood furniture surfaces, etc.