How Does a 3 Phase Motor Work with 1 Phase Power Supply?

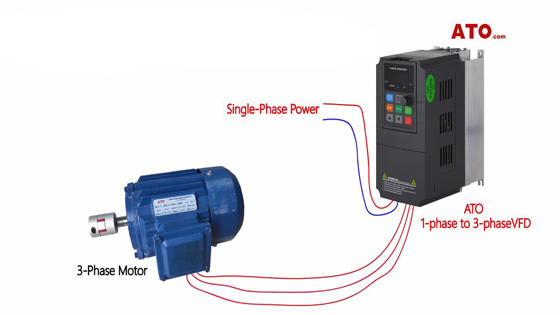

Can a three-phase 220V-240V motor work with a single-phase 220V supply? ATO single-phase VFD can do it. It can convert 1-phase 220V-240V into 3-phase to supply power to a three-phase motor, and can also reduce the inrush current when the motor starts.

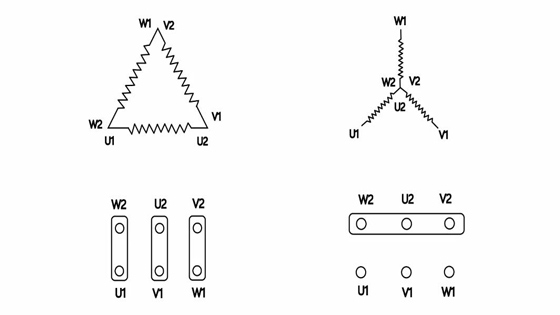

Before running, we need to know the internal wiring of the 3-phase motor.

Modification principle

Connect a capacitor, and use the capacitor or inductance phase-shift method for one phase winding coil, so that two phases pass different currents so that a rotating magnetic field can be established to start the motor, which is equivalent to a three-phase asynchronous motor Modified into a single-phase asynchronous motor.

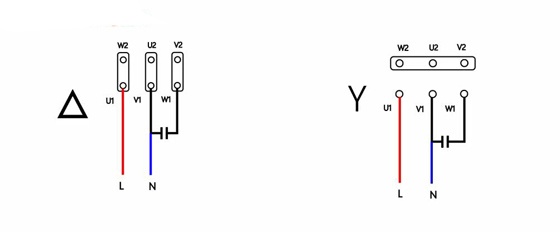

Connect diagram

Some advice

- If the motor is originally in a star connection, it is better to change to a delta connection, because the power attenuation will be more after the star connection is changed.

- In the case of 220V single-phase electricity as an example, the capacity of the capacitor can be estimated at 70~80μF per 1kW.

- It is best to use pressure-resistant oil-intrusion capacitors above 450V.

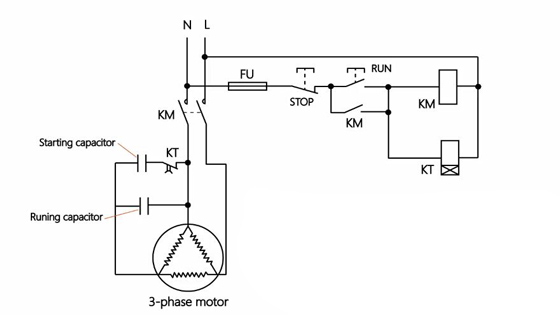

Complete circuit diagram

Install the starting capacitor and the running capacitor, and use a KT (timer relay) to control the on and off of the starting capacitor, and automatically cut off the starting capacitor line section after the motor runs. When the motor power is greater than 1kW, it is recommended to add a starting capacitor.

Only need to connect to a single-phase power supply to run a three-phase motor. ATO 1-phase to 3-phase VFD (Variable Frequency Drive) is a good choice.

VFD terminal control

Press the white button and the motor starts to rotate clockwise.

VFD potentiometer control

I Rotate the potentiometer and the motor starts to run normally.

VFD multi-speed control

K3 (X1 ~ X3) has seven different combinations, so it can set seven different running speeds.

VFD analog signal control

- Input 4mA analog current to the VFD and the VFD frequency is 0Hz.

- Increasing the VFD input current, the output frequency becomes large and the motor speed becomes fast.

- When the input reaches 20mA, the VFD output frequency is 50Hz at the maximum.

VFD & PLC communication control

When 10.03 is turned on, the VFD starts and the frequency gradually rises to the set value. The parking area monitoring display is normal.

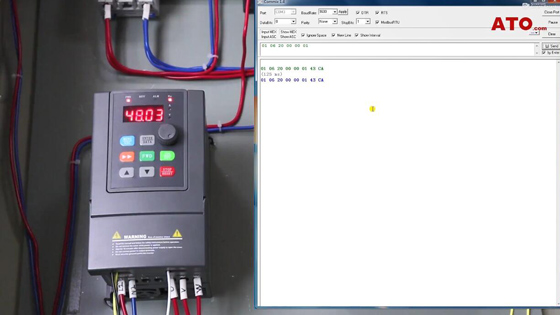

VFD Modbus control

VFD sensor control

- Lift the pressure sensor to reduce the pressure it receives.

- After decreasing to a certain extent, the VFD starts and the frequency rises to the motor running frequency.

- When pressing "Rated Hz" of HMI, the frequency of VFD is modified to 50Hz.

VFD HMI control

Press "RUN" on the HMI, the VFD starts to run and the motor starts to rotate.

By using ATO VFD, 3-phase motors can be run, stopped, forward, reverse and speed control freely. If you want to see more details of the video, please check: